Specac Gateway GS11155 User manual

Gateway™ ATR Electrically

Heated Trough Top Plate

User Manual

2I-11155-16

List of Safety Symbols

Safety Symbol

Meaning

General Caution.

(Reference ISO 7000-0434B, 2004-01)

Caution – Hot Surface.

Reference IEC 60417-5041, 2002-10)

Caution – Possibility of Electric Shock

Indoor Use Only

Electrical Safety

Warning: The temperature controller supplied with the this

accessory is Class 1 (earthed) construction and must be

connected to an earthed mains socket outlet.

Warning: Disconnect the mains from the temperature

controller before cleaning. Clean only with a soft cloth,

lightly moistened with water.

Gateway™ ATR Electrically

Heated Trough Top Plate

User Manual

2I-11155-16

User Manual

2

Gateway™ ATR Electrically Heated Trough Top

Plate P/N GS11155

CONTENTS

1. INTRODUCTION ................................................................................. 3

2. SAFETY CONSIDERATIONS ................................................................ 5

3. UNPACKING AND CHECKLIST ............................................................. 6

4. ALIGNMENT OF THE GATEWAY™ ATR HEATED TROUGH TOP PLATE .. 7

FITTING THE GATEWAY™ ATR HEATED TROUGH TOP PLATE ............. 8

5. ANALYSING DIFFERENT SAMPLE TYPES ........................................... 10

LIQUID SAMPLING ........................................................................... 10

PASTE SAMPLES ............................................................................ 11

SEMI-SOLID SAMPLES (FILMS) ........................................................ 12

6. ATR CRYSTAL REMOVAL AND REPLACEMENT .................................. 14

CRYSTAL REMOVAL FROM THE HEATED TROUGH TOP PLATE ............ 14

CLEANING THE KALREZ GASKET ...................................................... 16

REPLACING THE CRYSTAL IN THE TOP PLATE ASSEMBLY .................. 18

CLEANING THE GATEWAY™ ATR HEATED TROUGH TOP

PLATE INTACT................................................................................ 19

NOTES ON CLEANING ...................................................................... 20

DATA SHEET FOR ZINC SELENIDE .................................................... 22

DATA SHEET FOR GERMANIUM ........................................................ 23

DATA SHEET FOR SILICON .............................................................. 24

7. GATEWAY™ ATR HEATED TROUGH TOP PLATE OPERATING

PARAMETERS ................................................................................. 25

8. GATEWAY™ ATR HEATED TROUGH TOP PLATE "BUBBLE NUMBER"

PART IDENTIFICATION ..................................................................... 27

9. GATEWAY™ ATR HEATED TROUGH TOP PLATE SPARE PARTS ........ 27

10. GATEWAY™ ATR TECHNICAL SPECIFICATION… ............................. 28

11. GATEWAY™ ATR HEATED TROUGH TOP PLATE SERIAL NUMBER ... 29

© April 2016 Specac Ltd. All rights reserved.

Brilliant Spectroscopy is a trademark of Specac Ltd.

Other product names mentioned herein may be trademarks

of their respective owners.

Gateway™ ATR Electrically Heated Trough Top Plate

3

1. Introduction

Thank you for purchasing a Specac Product.

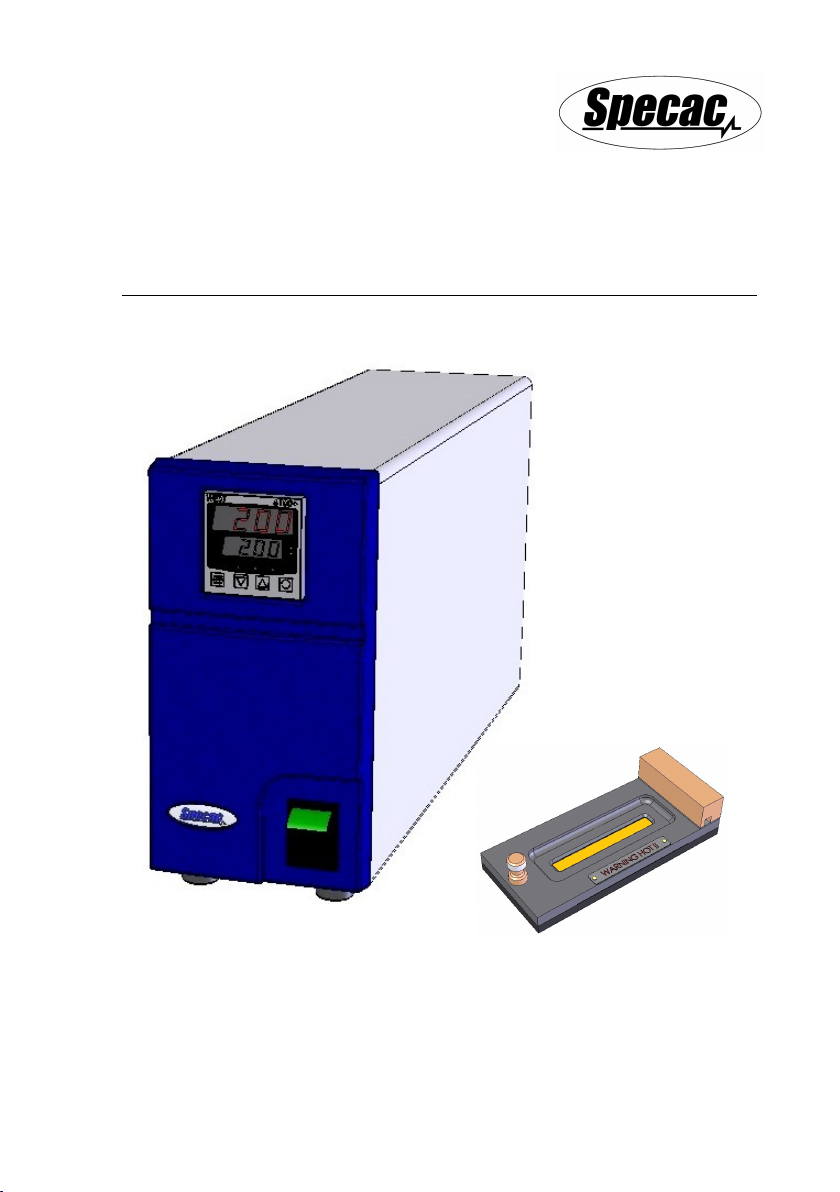

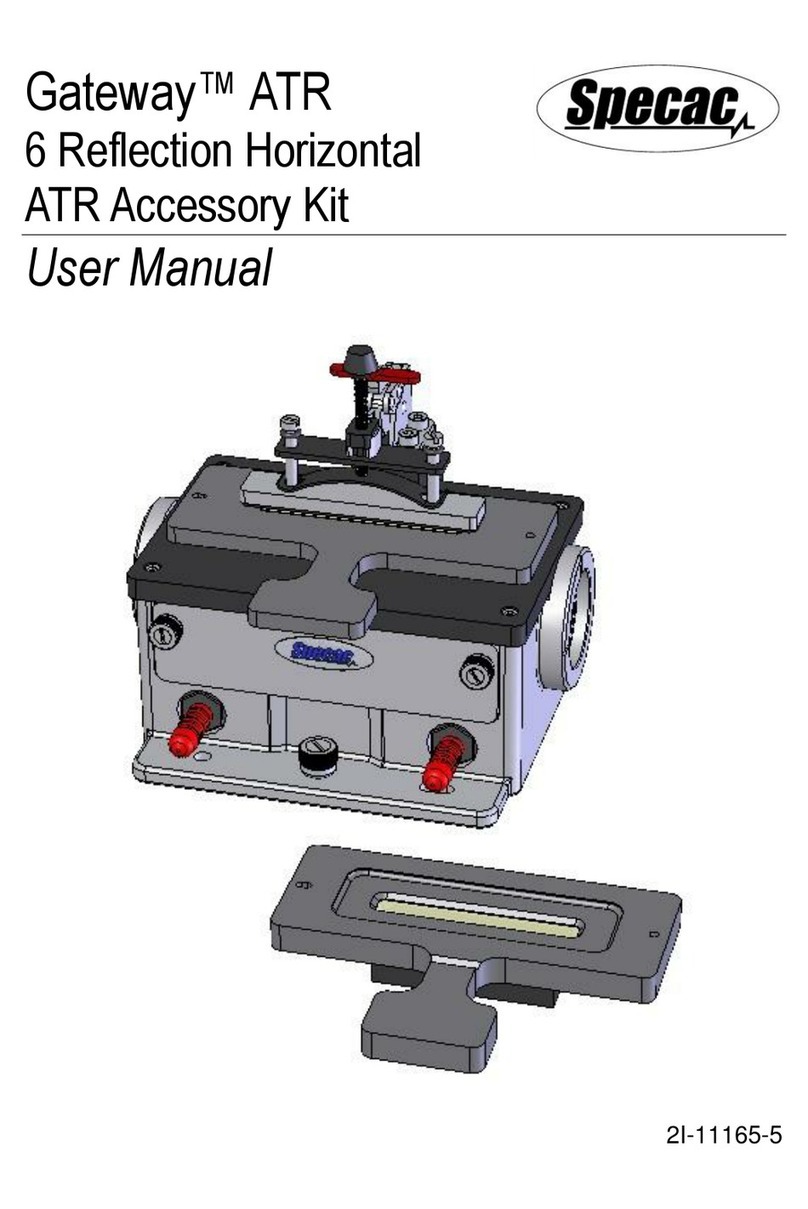

This user instruction manual for the Gateway™ ATR Electrically

Heated Trough Top Plate P/N GS11155 is to be used in conjunction

with the user instruction manual provided for the Gateway™ 6

Reflection ATR Accessory against P/N GS11165 (2I-11165-4).

Understanding of the Gateway™ ATR Accessory itself helps in usage

of any alternative ATR Top Plates that are compatible with this ATR

system.

The Gateway™ ATR Electrically Heated Trough Top Plate P/N

GS11155 is an alternative Top Plate that can be used on the optical

unit (P/N GS11170) of the Gateway™ ATR Accessory. The Gateway™

ATR Accessory supplied as standard for a kit of parts under P/N

GS11165, provides for an optical unit (GS11170), a trough top plate

assembly fitted with a 45° ZnSe crystal (GS11166), a flat top plate

assembly fitted with a 45° ZnSe crystal (GS11133) and a clamp

assembly (GS11171). (See user instruction manual 2I-11165-3).

Note: Any Gateway™ ATR Top Plate assembly can also be used on

older Benchmark™ ATR optical units, P/N’s GS11160, GS11110

and GS11180.

Using the Gateway™ ATR Electrically Heated Trough Top Plate in

conjunction with any of the above optical unit systems, a liquid sample

can be held static over a 6 Reflection event ATR crystal to be studied

from ambient up to 200°C temperatures, the temperature being set in

1°C steps over the entire range. Chemical interactions for the mixing of

sample species at varying temperatures may also be monitored. (e.g. a

solid sample can be deposited onto the ATR crystal and a fluid can be

placed over the sample to observe any changes spectroscopically.)

Power is applied to raise the temperature of the Top Plate assembly by

use of a dedicated 4000 Series™ Temperature Controller. A separate

user instruction manual is supplied for use and understanding of the

controller to operate the Heated Top Plate assembly.

User Manual

4

Usually, a liquid sample to be analysed is just simply placed to cover

over the ATR crystal analysis area of the Trough Top Plate assembly.

However, thin polymer films or semi-solid type samples can also be

analysed spectroscopically if the film is cut to the approximate size of

the crystal surface area and the Gateway™ ATR clamp assembly

mechanism is employed. A PTFE pressure pad piece is supplied to

enable this type of sampling to be carried out.

The Gateway™ ATR Electrically Heated Trough Top Plate has been

designed with the capability to remove the ATR crystal for thorough

cleaning or using a replacement ATR crystal material in the Top Plate

if desired. Any of the crystal materials usable with the Gateway™ ATR

system – ZnSe, germanium or silicon – can be placed into the

Gateway™ ATR Electrically Heated Trough Top Plate, although

germanium loses its spectral IR transmission capability with a

progressive rise in temperature, becoming completely opaque at

temperatures of circa 100°C and above.

As a standard offering for P/N GS11155, a 45° angle ZnSe crystal (P/N

GS11145) is fitted. The ATR crystal options are:

P/N GS11145 - Gateway™ ZnSe crystal, 45° angle.

P/N GS11146 - Gateway™ Silicon crystal, 45° angle.

P/N GS11147 - Gateway™ Germanium crystal, 45° angle.

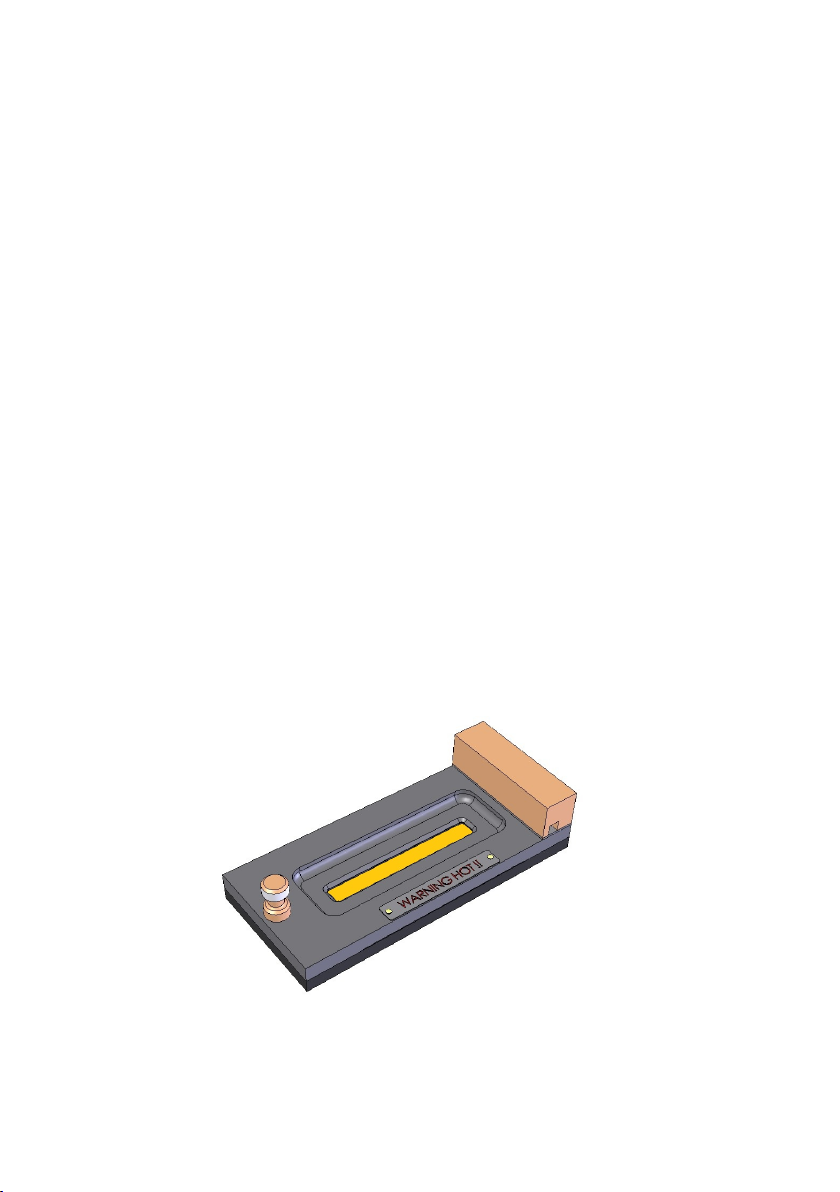

Fig 1. Gateway™ ATR Electrically Heated Trough Top Plate

Gateway™ ATR Electrically Heated Trough Top Plate

5

2. Safety Considerations

With use of any spectroscopic accessory that involves the study of a

wide range of chemical samples, the associated risk in handling may

mostly be attributed to the specific sample type to be handled itself. As

far as it possible you should follow a procedure for safe handling and

containment of the type of sample to be used.

With respect to safety of use specifically to the Gateway™ ATR

Accessory, this uses different crystal materials for the ATR crystal

Trough, Flat and Flow Through Top Plate assemblies where a sample

is bought into contact for analytical spectroscopic study. As standard,

Zinc Selenide (ZnSe), germanium (Ge) and Silicon (Si) are the three

crystal materials of choice that can be used.

Caution: Out of these three different crystal types, ZnSe is

the most potentially hazardous material with respect to

toxicity risk in use and handling.

Both Ge and Si crystal materials can be considered relatively safe to

use, although Ge may be harmful to the body if it is ingested in

significant quantity. The general rule when working with any crystal

material (and sample) is to always wear gloves and safety gear (e.g.

safety spectacles) when handling to obviate the risk of contact with the

skin.

Provided with each ATR crystal version of top plate assembly is a

window material safety data sheet for the crystal material itself that can

be consulted for safe handling. A copy of each of these datasheets can

also be found in the Gateway™ ATR instruction manual (2I-11165-4) in

the Notes on Cleaning Section found on pages 42, 43 and 44.

General Operational Safety Use

Caution: Always follow local laboratory safety protocols

and procedures when using potential toxic or flammable

substances with this equipment. The equipment is

intended for use by suitably trained personnel only.

User Manual

6

Caution: No user serviceable parts within the temperature

controller supplied, contact the manufacturer or approved

service agent for advice if the product is not functioning

correctly or is visibly damaged.

Caution: If the equipment is used in a manner not

specified by the manufacturer, the protection provided by

the equipment may be impaired

Warning: Risk of burns when operated at high

temperatures on accessible parts surrounding the heated

assembly.

End of Lifetime Equipment Use

If any parts have reached their limit of lifetime and need to

be replaced, use appropriate WEEE and other local

regulations for the safe disposal of electrical equipment

and toxic chemicals.

Gateway™ ATR Electrically Heated Trough Top Plate

7

3. Unpacking and Checklist

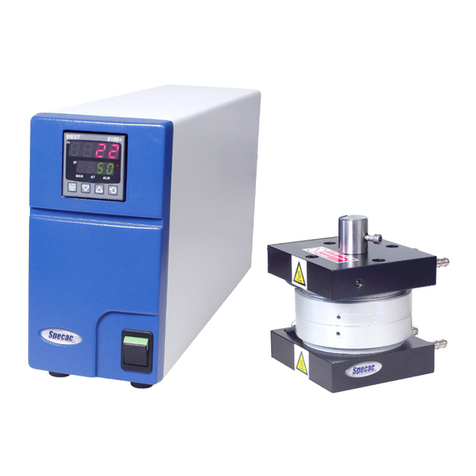

The Gateway™ ATR Electrically Heated Trough Top Plate and its

dedicated 4000 Series Temperature Controller are supplied packed in

a black plastic carry case and cardboard box respectively.

The carry case contains the following:

Electrically Heated Trough Top

Plate with Zinc Selenide crystal

(or as specified from germanium

and silicon options) and integral

power/thermocouple connectivity

cable.

ATR spectrum of the crystal as fitted to the Top Plate assembly to

show its background throughput.

PTFE pressure bar.

Plastic spatula.

Allen Key (2.5mm A/F)

The cardboard box contains the following:

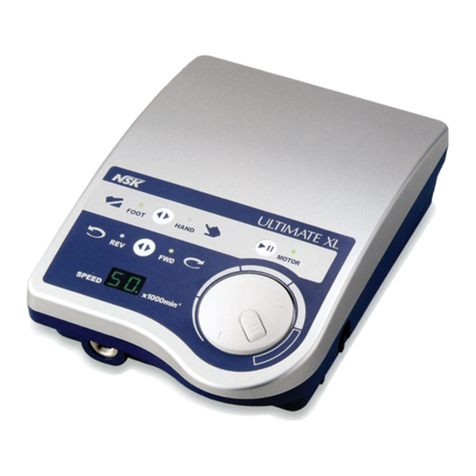

4000 Series Temperature Controller

dedicated for control of the Gateway™

ATR Electrically Heated Top Plate.

Appropriate mains power cable.

Instruction manual for the 4000 Series

Temperature Controller.

Remove the items carefully from their packaging in preparation for

installation and use.

User Manual

8

4. Alignment of the Gateway™ ATR Electrically

Heated Trough Top Plate

The Gateway™ ATR Electrically Heated Trough Top Plate is to be

installed onto the optical unit (GS11170) of the Gateway™ ATR

Accessory for operation in the study of static liquids or semi-solid

samples and thin films over the temperature conditions from ambient to

200°C. This Trough Top Plate should be optimised for its energy light

throughput from a particular alignment of the mirrors on the optical

when installed for use.

If the Gateway™ ATR Accessory (as the Kit GS11165) is available for

use, please follow the instruction manual supplied (2I-11165-4) for the

alignment procedure to optimize the liqht energy throughput of the ATR

system on your particular spectrometer using either the Trough Top

Plate (GS11166) or Flat Top Plate (GS11133) assembly as supplied.

The input and output mirror settings for their rotation and tilt angles will

be established on the optical unit (GS11170) from the alignment

procedure using either of these two Top Plates.

When subsequently placing the Electrically Heated Trough Top Plate

onto the optical unit as a replacement for either the Trough (GS11166)

or Flat (GS11133) Top Plate assembly, a signal throughput will be

registered, but it is possible the mirrors in the optical unit may require

slight re-adjustment for an optimum throughput to be established in

use of this alternative Trough Top Plate. Follow the alignment

procedure with the Electrically Heated Trough Top Plate in position to

obtain the best throughput energy signal for the spectrometers system.

Note: If just the Gateway™ optical unit (GS11170) and an Electrically

Heated Trough Top Plate are available to use, unless the optical

unit has been pre-aligned to register some energy throughput

with a Top Plate in position, then it may be difficult to gain an

optimum alignment using the FTIR spectrometer systems energy

source and detection system. A rough pre-alignment is to be

established with the optical unit and Electrically Heated Trough

Top Plate in position using a visible light source such as the

Laser Alignment Accessory (P/N GS24500).

Gateway™ ATR Electrically Heated Trough Top Plate

9

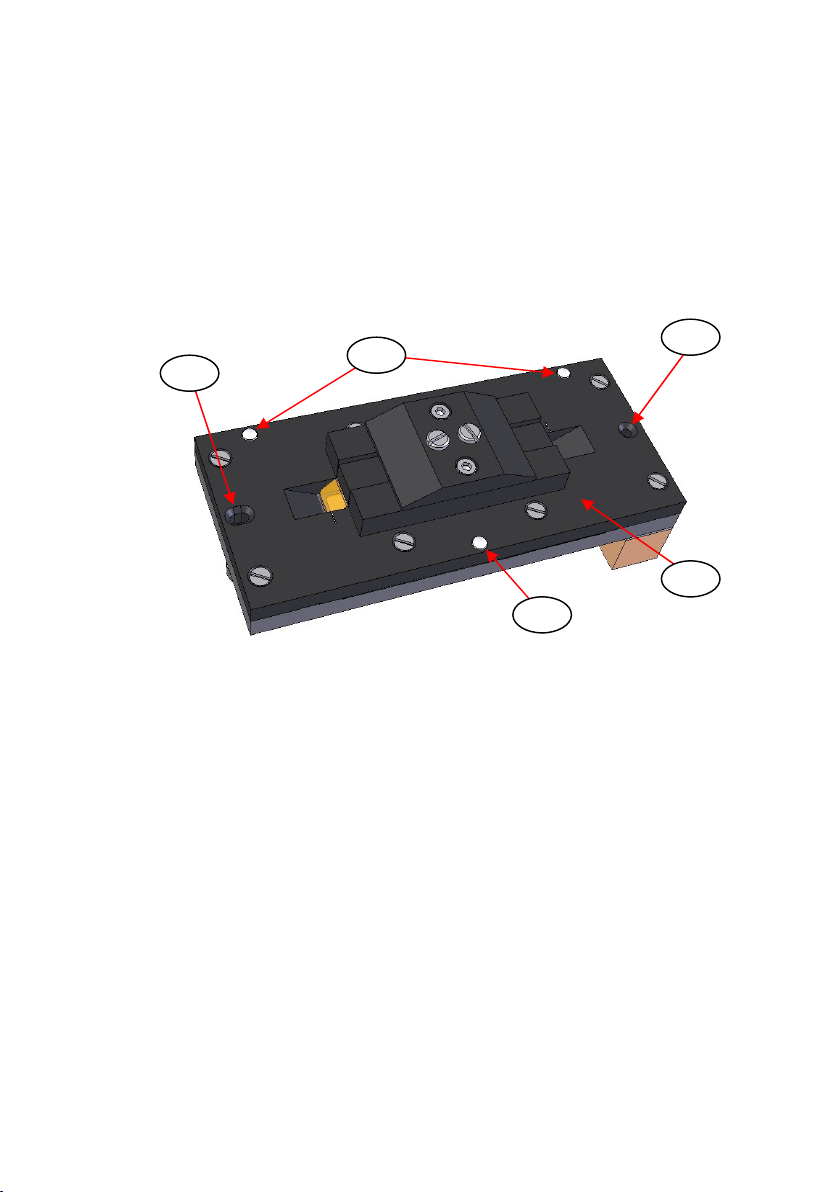

Fitting the Gateway™ ATR Electrically Heated Trough Top

Plate

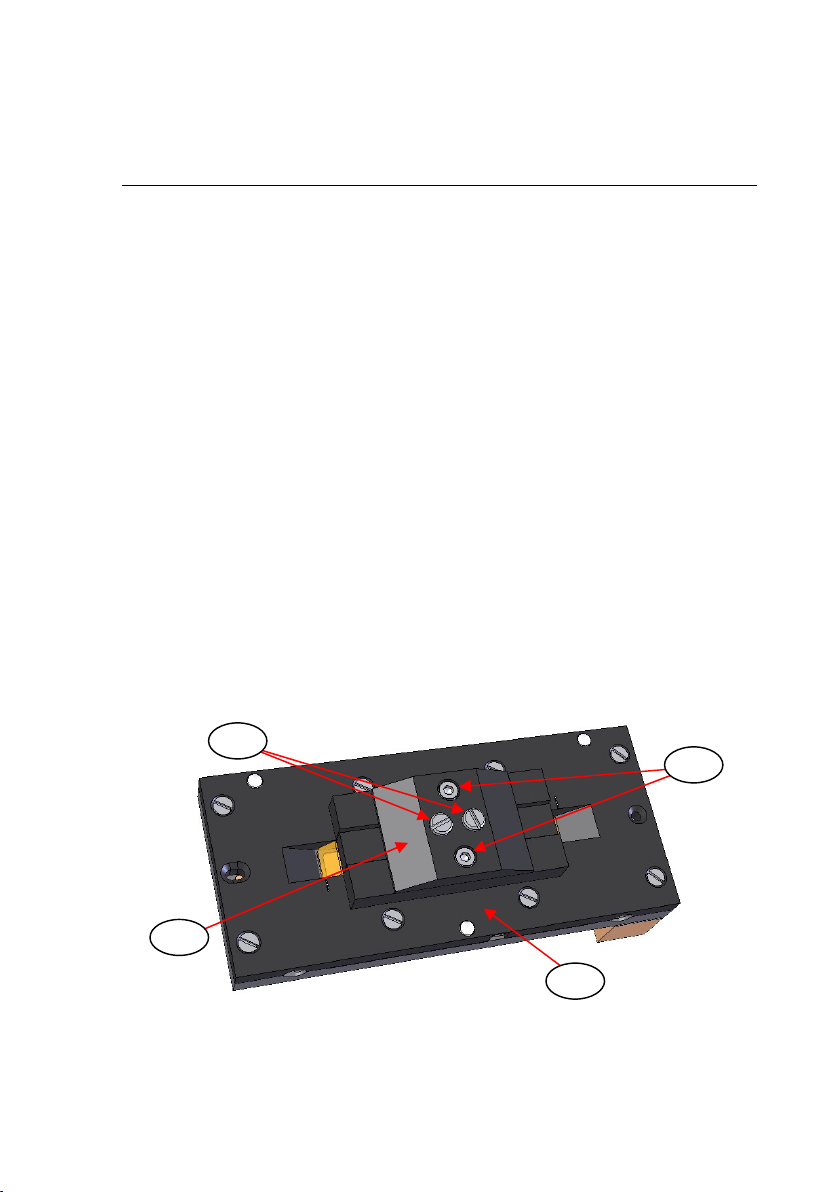

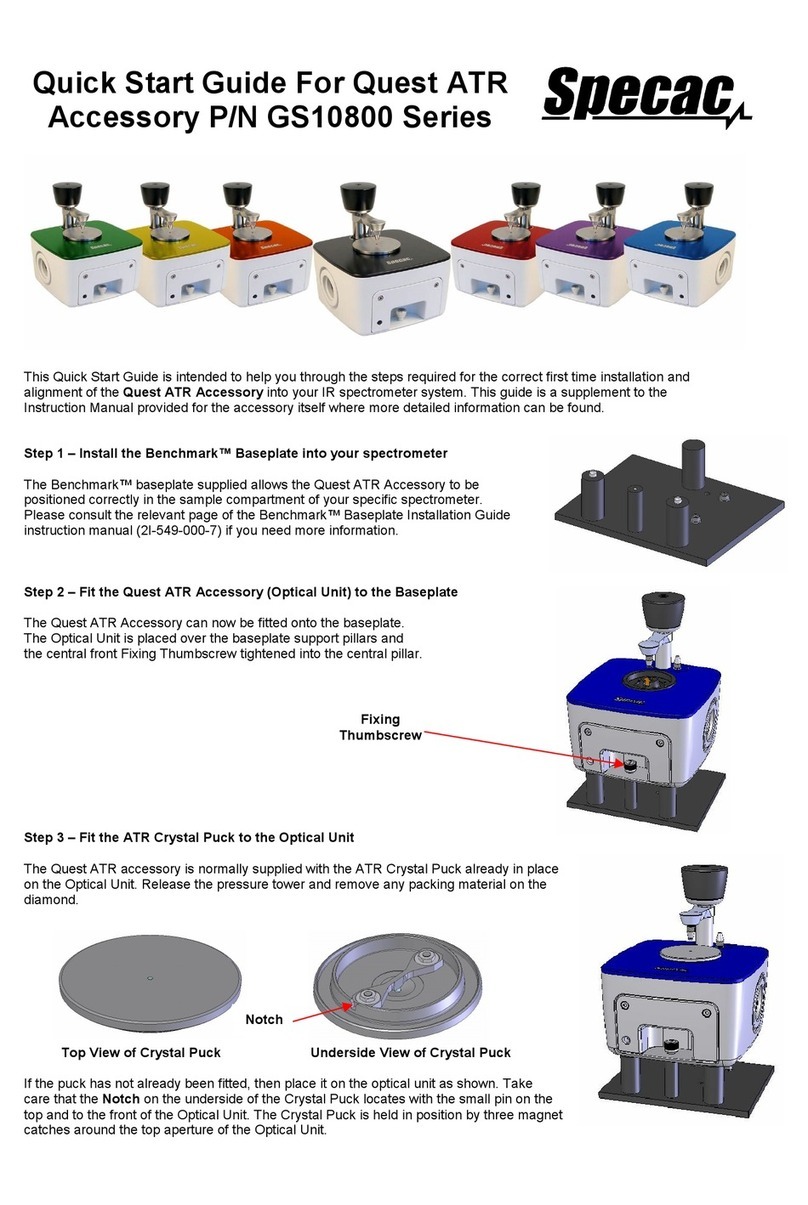

The Gateway™ ATR Electrically Heated Trough Top Plate fits onto the

top of the Gateway optical unit via alignment of the round hole (1) and

slot hole (2) on the underside of the Top Plate over the two fixing

location pins (3) on the optical unit. (See Fig 2 and Fig 3.)

Fig 2. Round and Slot Location Holes on Underside of

Gateway™ ATR Electrically Heated Trough Top Plate

The Gateway™ ATR Electrically Heated Trough Top Plate is fitted and

positioned the correct way around on the optical unit when the round

hole (1) is placed over the right side location pin (3R) and the slot hole

(2) is placed over the left side location pin (3L) as viewed from the

front of the optical unit. The main body plate (4) of the Top Plate

assembly should be resting on its three PTFE stand-off feet (5) onto

the top surface of the optical unit when properly located.

Note: To maintain a correct optical alignment for consistency of optical

throughput energy of the Gateway™ ATR Electrically Heated

Trough Top Plate, it should always be placed onto the optical

unit the same way around after removal for cleaning or crystal

replacement etc, with the round (1) and slot (2) holes fitting over

their correct and respective fixing location pins (3R) and (3L).

2

1

4

5

5

User Manual

10

Important: Care must also be taken to see that from installation there

is no unnecessary stress or strain applied to the integrally

fitted power/thermocouple cable, which could cause

damage to the thermocouple. Avoid sharp bends of this

cable at the end attached to the Heated Trough Plate.

Fig 3. Fitting of Gateway™ ATR Electrically Heated Trough

Top Plate to the Gateway™ Optical Unit

1

2

4

3L 3R

R

Gateway™ ATR Electrically Heated Trough Top Plate

11

5. Analysing Different Sample Types

When the Gateway™ ATR Electrically Heated Trough Top Plate has

been correctly installed onto the optical unit and aligned, then its

integral power and thermocouple cable assembly with the six-way

bayonet plug of the Top Plate assembly is to be connected to its

appropriate socket at the rear of the 4000 Series Temperature

Controller. The bayonet plug is push fitted and turned to click into the

Controllers socket connection.

Note: Please refer to the instruction manual supplied for the 4000

Series Controller to make the connection and how to heat and

control the temperature to the Electrically Heated Trough Top

Plate assembly.

In operation for collection of a background spectrum and then a

sample spectrum (see Spectral Collection Using the Gateway™ ATR

Accessory from the instruction manual 2I-11165-3), ideally the

temperature conditions for both spectral acquisitions should be the

same. The parameters of operation for the Electrically Heated Trough

Top Plate have been specifically set on its 4000 Series Controller to

allow for a maximum temperature rate rise of 10°C per minute. Any

higher rate rise risks introducing thermal shock to the ATR crystal (6) in

the Top Plate assembly and causing damage. For the parameter listing

set on the supplied 4000 Series Controller, please refer to section 7),

pages 25 and 26 of this user instruction manual.

Liquid Sampling

Liquids can be poured onto the crystal (6) of the Gateway™ ATR

Electrically Heated Trough Top Plate or introduced by the use of a

pasteur pipette.

The liquid should cover the entire ATR crystal (6) surface where the

sample is being heated. It is important that a sufficient volume of

sample is applied so that the crystal (6) is not left exposed during any

spectral measurement, if there is any vaporization of the sample

because of an elevation in the temperature above ambient conditions.

User Manual

12

As much of a liquid sample should be removed from the crystal (6)

area with a pasteur pipette when the Heated Trough Top Plate

assembly is cool to touch if any elevated temperature measurements

have been taken. It is recommended that the Heated Trough Top Plate

is also removed away from the optical unit to a safe area for cleaning

before introducing the next sample or after use. This prevents potential

accidental contamination of the optical unit parts and the sample

compartment area of the spectrometer.

Note: Removal of the Top Plate assembly from the optical unit to clean

in a safe working area may also require disconnection of its

power and thermocouple cable from the 4000 Series Controller.

If the liquid sample solidifies against the ATR crystal (6) when the Top

Plate assembly cools from an elevated temperature measurement, it

may be easier to remove most of the sample when hot, by very

carefully using the pipette and wiping the remainder of any sample

away from the ATR crystal (6) with a soft lens cleaning tissues while

cooling. Remove the last traces of the sample when the Top Plate

assembly has cooled sufficiently to handle by using fresh tissues

soaked in a suitable solvent.

Warning: Do not remove the Heated Trough Top Plate for

cleaning when hot as it can cause serious burns.

Paste Samples

Apply the paste lightly to cover the ATR crystal (6) surface completely

using the plastic spatula as supplied.

Similar to liquid sample handling, remove the sample by wiping clean

using a soft lens cleaning tissues when the top plate has cooled

sufficiently. Remove the last traces of the sample by using fresh

tissues soaked in a suitable solvent.

If the paste sample solidifies against the ATR crystal (6) when the Top

Plate assembly cools from an elevated temperature measurement, it

may be easier to remove most of the sample when hot, by very

Gateway™ ATR Electrically Heated Trough Top Plate

13

carefully using soft lens cleaning tissues to wipe the sample clear of

the crystal (6) while cooling. Remove the last traces of the sample

when the Top Plate assembly has cooled sufficiently to handle by

using fresh tissues soaked in a suitable solvent.

Warning: Do not remove the Heated Trough Top Plate for

cleaning when hot as it can cause serious burns.

Semi-Solid Samples (Films)

Although the Electrically Heated Trough Top Plate has been

specifically designed for the ATR measurement of liquid sample types

at elevated temperatures up to 200°C, flexible semi-solid, film type

samples can be analysed by use of this Top Plate with the supplied

PTFE pressure bar (7) and employment of the Gateway™ ATR Clamp

Assembly fitted to the optical unit. (See Fig 4.)

Fig 4. PTFE Pressure Bar Used With Electrically Heated

Trough Top Plate

7

6

User Manual

14

To analyse a semi-solid sample such as a thin film, the film sample

must be prepared by cutting to size to cover over the entire surface of

the ATR crystal (6) in the recess of the trough area. The PTFE

pressure bar (7) is then very carefully placed over the film surface on

top of the crystal (6). The PTFE pressure bar (7) allows for a sufficient

height above the surrounding recessed trough area to transfer the

force that is to be applied from use of the clamp assembly. Please

refer to installation and operation of the clamp assembly when on the

optical unit from the Gateway™ ATR instruction manual 2I-11165-3,

pages 9 to 12.

Exercise great care when sampling for semi-solid types. Apply a

load from the clamp assembly to give sufficient sample contact to

register an ATR spectrum for the sample. Any temperature can be

selected from ambient to 200°C to measure for the sample, but be

careful if the film sample is subject to melting, burning or charring at

elevated temperatures in case of potential subsequent damage to the

Gateway™ ATR Top Plate components and crystal (6).

Note: The ATR crystal (6) is held liquid tight against an upper Kalrez

gasket seal (8) in the Gateway™ ATR Electrically Heated

Trough Top Plate by means of spring tensioning screws (9) in a

lower clamp pressure plate assembly (10). Do not apply too

much pressure from the clamp assembly to the crystal (6) as this

could force the crystal (6) to be detached from the upper Kalrez

gasket seal (8) in the main body plate (4) of the Top Plate

assembly. This event would result in loss of any applied heat to

the sample and possible leakage of the entire Top Plate

assembly when subsequently used for any liquid samplings.

Similar to liquid sample handling, after analysis remove the film sample

from the ATR crystal (6) and wipe clean using a soft lens cleaning

tissues when the top plate has cooled sufficiently, if elevated

temperatures have been used in any sample measurements. Remove

any last traces of the sample from the crystal (6) by using fresh tissues

soaked in a suitable solvent.

Gateway™ ATR Electrically Heated Trough Top Plate

15

6. ATR Crystal Removal and Replacement

The design of the Gateway™ ATR Electrically Heated Trough Top

Plate allows for the ATR crystal (6) to be removable for easier cleaning

or if damage occurs and the crystal needs to be replaced.

Crystal Removal from the Heated Trough Top Plate

If it is necessary to remove the crystal (7) for thorough cleaning of the

Top Plate assembly of parts or to replace any damaged parts etc, the

following procedure should be adopted.

Note: It is normally easier to work on the Top Plate assembly having

disconnected the power and thermocouple cable from the 4000

Series Controller.

Important: For safety precautions wear gloves when carrying out

the following procedure.

1) Lay the Top Plate assembly on to a clean workspace area and

proceed to remove the two M3 x 8mm cap head screws (11) from

the lower clamp pressure plate assembly (10) on the underside of

the Top Plate assembly using the 2.5mm A/F Allen key supplied.

Turn the screws (11) anticlockwise to remove. (See Fig 5.)

Fig 5. Underside of Heated Trough Top Plate Assembly

9

11

4

10

User Manual

16

Note: Do not touch the two slot head tensioning screws (9) as these

hold the components of the lower clamp plate assembly (10)

together for containment of the internal springs.

2) Between the underside of the lower clamp plate assembly (10) and

the ATR crystal (6) there is a protective lead pad (12). Carefully

remove the lower clamp plate assembly (10) away to gain access to

the lead pad (12). (See Fig 6.) The lead pad (12) may be stuck

close to the underside of the crystal (6) and so it needs to be

removed very carefully away from the crystal.

Note: The lead pad (12) will be needed in any re-assembly after

cleaning of parts or if replacing with a new crystal (6).

Fig 6. Lead Pad on Underside of ATR Crystal with Removal of

Lower Clamp Pressure Plate Assembly

3) If the lead pad (12) has adhered to the crystal (6), then it may be

easier to remove it carefully away from the crystal when the crystal

4

10

6

12

9

9

Gateway™ ATR Electrically Heated Trough Top Plate

17

(6) itself has been removed from its centralised position in its

recess of the main body plate (4). Therefore, support the crystal (6)

and the lead pad (12), with one hand and turn over the Top Plate

assembly so that the crystal (6) can fall out to drop into the palm of

your hand. If the crystal (6) is also stuck in the main body plate (4)

because of good sealing to the Kalrez gasket (8) on the top

(sampling) surface of the crystal (6), then put a soft pad or tissue on

the work bench area and lay the Top Plate assembly onto it the

same way up as it would be used when fitted to the optical unit.

Try to loosen the crystal (6) away from the Kalrez gasket (8) seal by

exerting a small pressure on either ends of the top of the crystal (6)

from inside the trough area and pushing down from above. Do not

press too hard in case the crystal (6) breaks. (ZnSe, in particular, is

a hard, but brittle crystal material.) If the crystal is stubborn to

movement try to lubricate the internal trough and Kalrez gasket (8)

area by use of some solvent (e.g. methanol) covering the top

surface of the crystal (6) whilst exerting the gentle pressure.

When the crystal (6) and the lead pad (12) have been removed, it may

now be easier to separate the lead pad (12) from the crystal. If the

crystals (6) top sampling surface looks OK and can be cleaned

carefully, then it may not be necessary to remove the lead pad (12)

away for further cleaning prior to re-assembly and use. However, if the

lead pad (12) is to be removed, it may be necessary to immerse the

whole crystal (6) and lead pad (12) assembly in a beaker of water or

methanol solvent and apply a gentle “sonication cleaning” of the items.

The action of the sonic agitation of the solvent may help to loosen the

lead pad (12) away from the crystal such that when the items are

removed from the solvent they can be easily and safely separated

without any damage to the lead pad (12) or crystal (6) parts.

Clean the ATR crystal (6) by following the Notes on Cleaning

instructions on page 20.

Cleaning the Kalrez Gasket Seal

When the ATR crystal (6) has been removed from the Top Plate

assembly, access can be gained to the Kalrez gasket seal (8) for

cleaning if necessary. (See Fig 7.)

User Manual

18

Fig 7. Kalrez Gasket Seal in the Gateway™ ATR

Electrically Heated Trough Top Plate

If a new Kalrez gasket seal (8) is needed, this is specially cut to fit

from Kalrez sheet material. The procedure is best done by Specac as

further dis-assembly of the Top Plate is required to replace a new

Kalrez gasket (8) seal and for re-fitting of a new ATR crystal (6) into

position within the Electrically Heated Trough Top Plate assembly.

Warning: Further dis-assembly of the Top Plate for the Kalrez gasket

(8) replacement exposes electrical components which should

not be touched other than by qualified electrical personnel.

If a new Kalrez gasket (8) is ever required, please contact Specac at

techsupport@specac.co.uk to arrange for return of the item to Specac

to carry out the service.

If however, after removal of the crystal (6) the Kalrez gasket (8) is in

good condition and only requires cleaning, then suitable solvents such

as water, methanol or acetone may be used to moisten a soft lens type

cleaning tissue or cotton bud to wipe around the gasket surfaces.

Note: Specac recommend that with removal or replacement of the

crystal (6), fitting a new Kalrez gasket (8) is the preferred option.

8

4

Table of contents

Other Specac Laboratory Equipment manuals

Specac

Specac Atlas GS15515 User manual

Specac

Specac Quest User manual

Specac

Specac ATMOS A2.5 User manual

Specac

Specac GS12000 Series User manual

Specac

Specac ARROW Instruction manual

Specac

Specac Golden Gate GS10640 User manual

Specac

Specac APEX QUICK RELEASE DIE User manual

Specac

Specac GS20600 User manual

Specac

Specac Selector GS19900 User manual

Specac

Specac Quest User manual

Specac

Specac Atmos User manual

Specac

Specac Quest ATR GS10800 Series User manual

Specac

Specac Atlas GS15640 User manual

Specac

Specac GS10890 User manual

Specac

Specac Gateway ATR User manual

Specac

Specac Golden Gate GS10500 Series User manual

Specac

Specac Storm 10H User manual

Specac

Specac Gateway ATR User manual