CONTENTS

3

1.PREFACE............................................................................................................................................

1.1 GENERAL SPECIFICATIONS

1.2 ORDERING INFORMATION

1.3 WARRANTY

1.4 MAINTENANCE

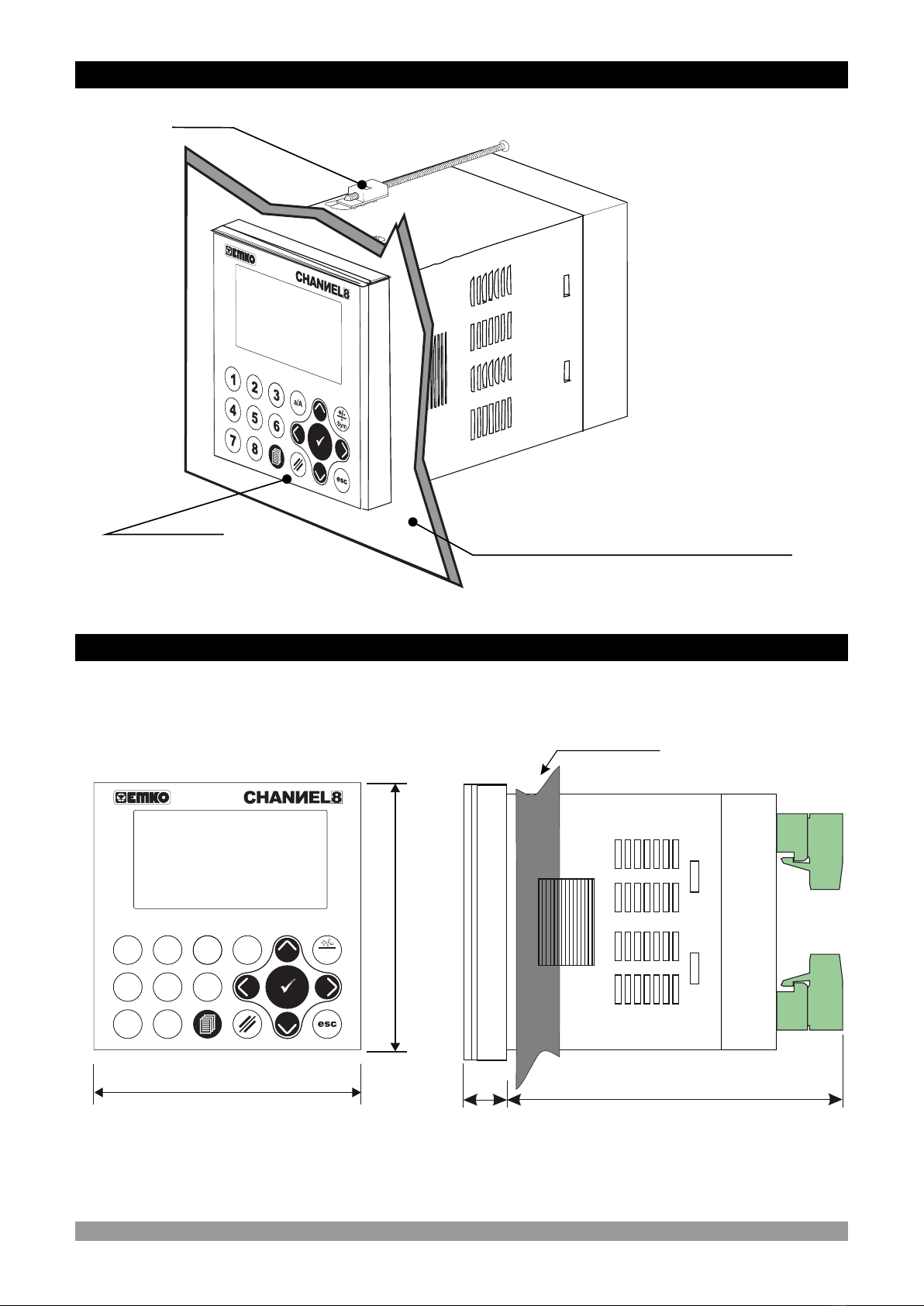

2.INSTALLATION....................................................................................................................................

2.1 GENERAL DESCRIPTION

2.2 FRONT VIEW AND DIMENSIONS OF EPLC9600-CHANNEL8

2.3 PANEL CUT-OUT

2.4 ENVIRONMENTAL RATINGS

2.5 PANEL MOUNTING

2.6 INSTALLATION FIXING CLAMP

2.7 REMOVING FROM THE PANEL

3.ELECTRICAL WIRING........................................................................................................................

3.1 TERMINAL LAYOUT AND CONNECTION INSTRUCTIONS

3.2 ELECTRICAL WIRING DIAGRAM

3.2.1 DEVICE WITH RELAY OUTPUTS

3.2.2 DEVICE WITH TRANSISTOR OUTPUTS

3.3 SUPPLY VOLTAGE INPUT CONNECTION OF THE DEVICE

3.4 SUPPLY VOLTAGE INPUT CONNECTION OF TRANSISTOR OUTPUTS

3.5. GALVANIC ISOLATION TEST VALUE OF EPLC9600-CHANNEL8 WITH RELAY OUTPUTS

3.6. GALVANIC ISOLATION TEST VALUE OF EPLC9600-CHANNEL8 WITH TRANSISTOR

OUTPUTS

4. CABLE CONNECTION BETWEEN RS232 TERMINAL OF THE DEVICE AND PC ........................

5. CONNECTION FOR RS485 SERIAL COMMUNICATION.................................................................

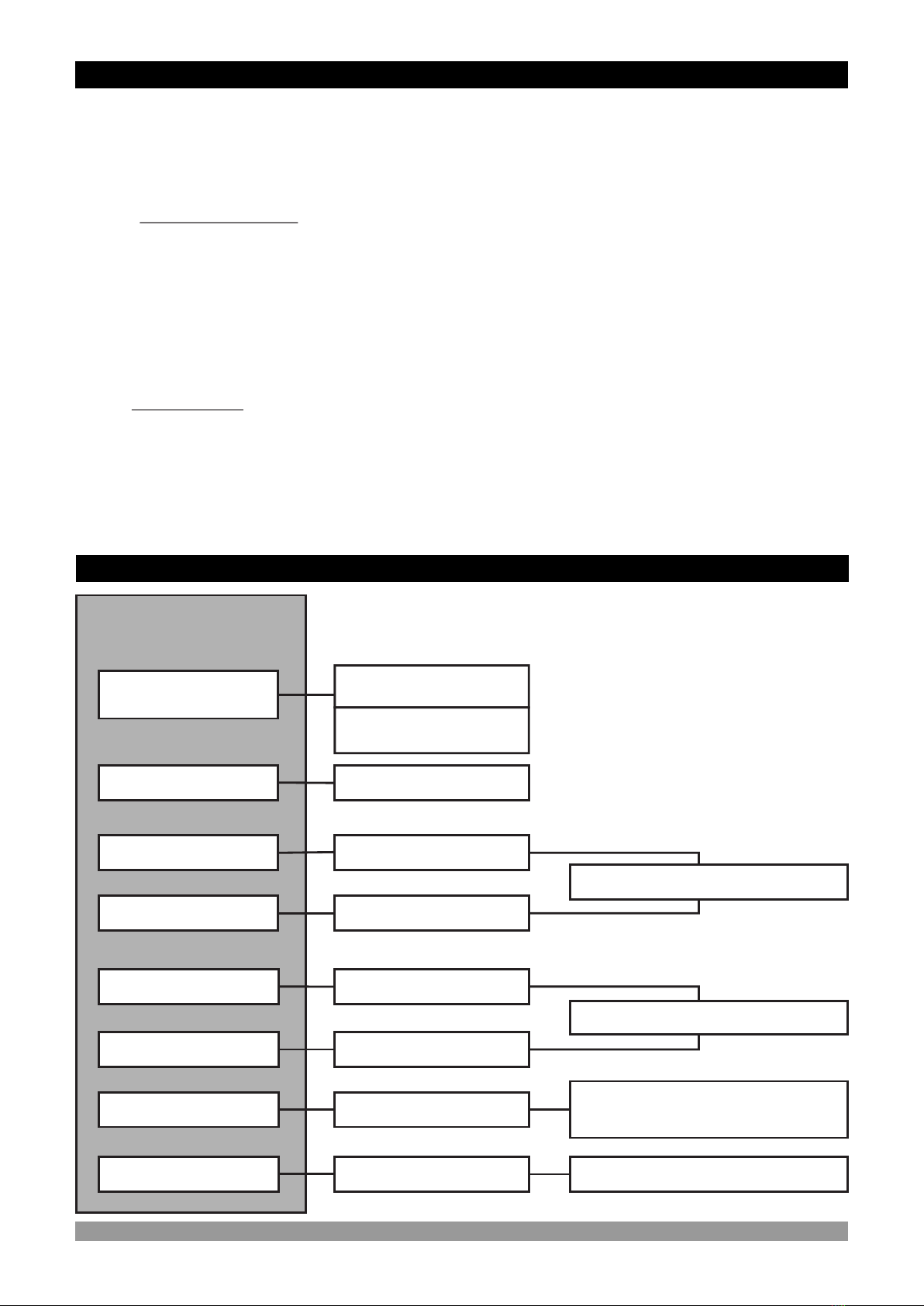

6. DEFINETION OF THE FRONT PANEL AND ACCESSING TO THE PARAMETERS.......................

6.1 DEFINETION OF FRONT PANEL

6.2 MAIN OPERATION SCREEN DEFINETION

6.3 ACCESSING TO THE OPERATOR PARAMETER PAGES

6.4 ACCESSING TO THE TECHNICIAN PARAMETER PAGES

6.5 OPERATOR PAGES PARAMETERS DEFINETIONS

6.6 TECHNICIAN PAGES PARAMETERS DEFINETIONS

6.6.1 PAGE-1 PARAMETERS

6.6.2 PAGE-2 PARAMETERS

6.6.3 PAGE-3 AND PAGE-4 PARAMETERS

6.6.4 RS232 SETUP PAGES PARAMETERS

6.6.5 RS485 SETUP PAGES PARAMETERS

6.6.6 USB SETUP PAGES PARAMETERS

6.6.7 ETHERNET SETUP PAGES PARAMETERS

6.6.8 REAL TIME (RTC) SETUP PAGES PARAMETERS

7.OPERATION GRAPHICS OF ALARM AND PRE-ALARM TYPE.......................................................

8.MODBUS ADDRESS...........................................................................................................................

8.1 OUTPUT ADDRESSES

8.2 PROCESS VALUES ADDRESSES

9.SPECIFICATIONS................................................................................................................................

10.OTHER INFORMATIONS..................................................................................................................

Page 5

Page 19

Page 12

Page 7

Page 40

Page 39

Page 41

Page 21

Page 20

Page 41