2

Cuffed Fast-Pac Injection Tube Assembly

Internal Mounting Instructions

The Fast-Pac tube assembly supplied with the humidifier(s), is designed for rapid dissipation of

steam. The tube assembly is designed for internal AHU or duct mounting. AHU/duct access must

be provided which allows the injection tube assembly to be located internally! The injection

tube assembly was sized to fit inside the AHU or duct dimensions.

VERIFY COMPONENTS

Unpack the components from the shipping container. Verify all components are checked off

according to the packing list and the COMPONENTS IDENTIFICATION DRAWING (Fig. 2).

Report any missing pieces to your local PURE Humidifier Co. representative immediately.

LOCATION

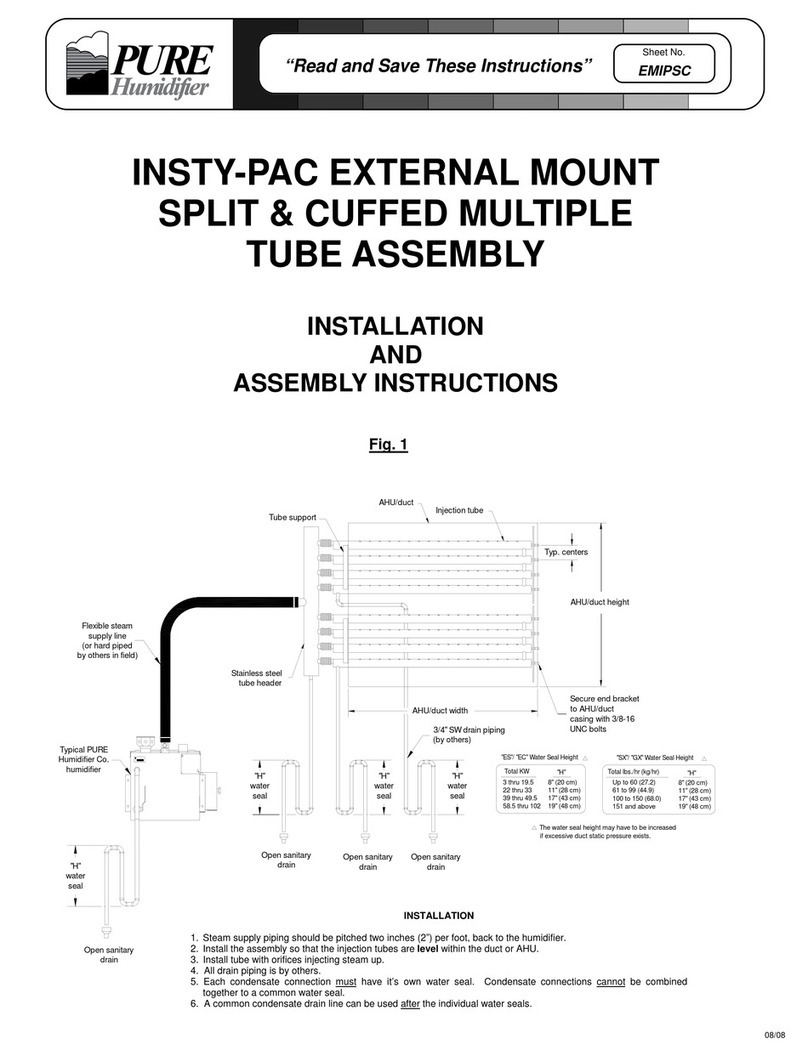

1.) Mount the injection tube assembly in the AHU or duct work as shown on the

project plans or as indicated by the engineer.

2.) Install the injection tube with the 3/4”-NPT drain connection, located on the tube header,

directed towards the bottom of the AHU or duct.

3.) Install the tube assembly so that the injection tubes are pitched back towards the header with

a minimum of two inches (2”) of pitch per foot.

4.) Install the tube assembly with the steam discharge ports facing upwards.

5.) The tube assembly should be centered in the AHU or duct height with an even distance

between the bottom tube and the casing floor and the top tube and the casing ceiling.

MOUNTING

1.) Layout the center lines for the injection tube SUPPLY and CONDENSATE connections.

The supply connections outside diameter may vary, the condensate connection is

1-1/16” outside diameter. Duct plates are provided to seal the opening. The layout should be

based on the “Location” instructions listed above (see Fig. 3).

2.) Cut a hole through the AHU or duct wall for the supply connection. If the alternate

horizontal condensate drain connection is supplied, cut a 1-1/16” diameter hole through

the AHU or duct wall, for the drain connection (see Fig. 3).

3.) Install the tube HEADER onto the inside of the AHU or duct wall with the steam supply

connection installed through the access hole (cut in step above). Secure the header to the

AHU or duct wall with 3/8-16 fasteners (by others). The HEADER is provided with header

mounting brackets welded onto the header (see Fig. 2)

4.) Slip one side of each of the FLEXIBLE CONNECTORS onto the 1 1/2” diameter stub-

outs on the HEADER and secure the FLEXIBLE CONNECTOR to the header with one

screw clamp per stub-out (see Fig. 2 & 3).

5.) Layout the injection tubes (quantity varies with order) and secure each INJECTION TUBE to

the TUBE SUPPORT BRACKET with the 3/8-16 fasteners provided making sure that the

orifices will be discharging upwards after installation (see Fig. 2 & 3).

6.) Slide the open end of each INJECTION TUBE into the open side of the matching

FLEXIBLE CONNECTOR. Secure each tube to the FLEXIBLE CONNECTOR by

tightening the matching screw clamp (see Fig. 2 & 3).

7.) Secure the END BRACKET to the AHU or duct wall with 3/8-16 fasteners (by others). The

END BRACKET must be located so that a minimum of two inches (2”) of pitch back towards

the header exists (see Fig. 3).

8.) Seal the openings where the STEAM SUPPLY and CONDENSATE connections

penetrate through the AHU or duct wall with the duct plates provided (see Fig. 3).

9.) Connect steam supply and condensate piping to the humidifier as illustrated in Fig. 1.