Page 4

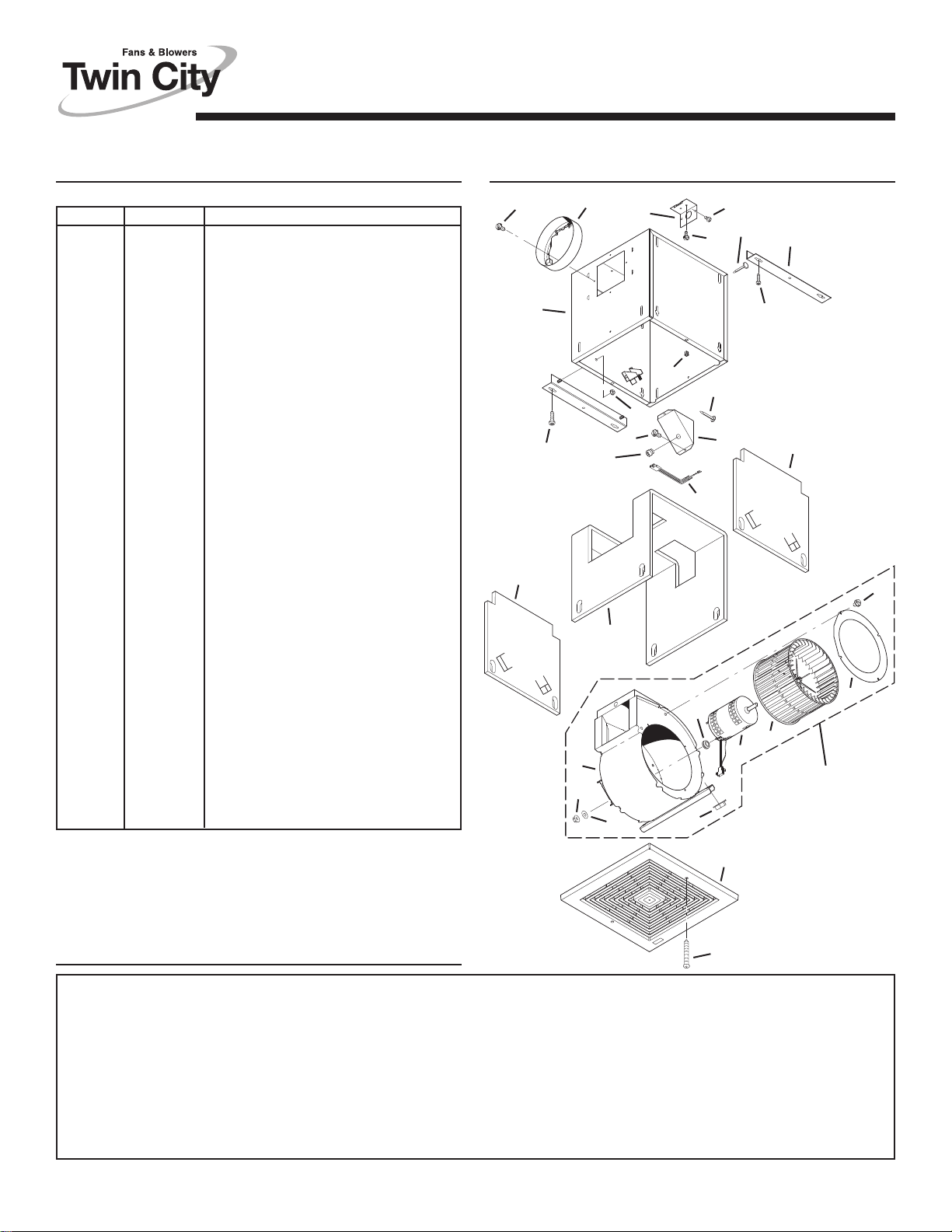

1

3

8

6

9

10

2

11

7

12

4

5

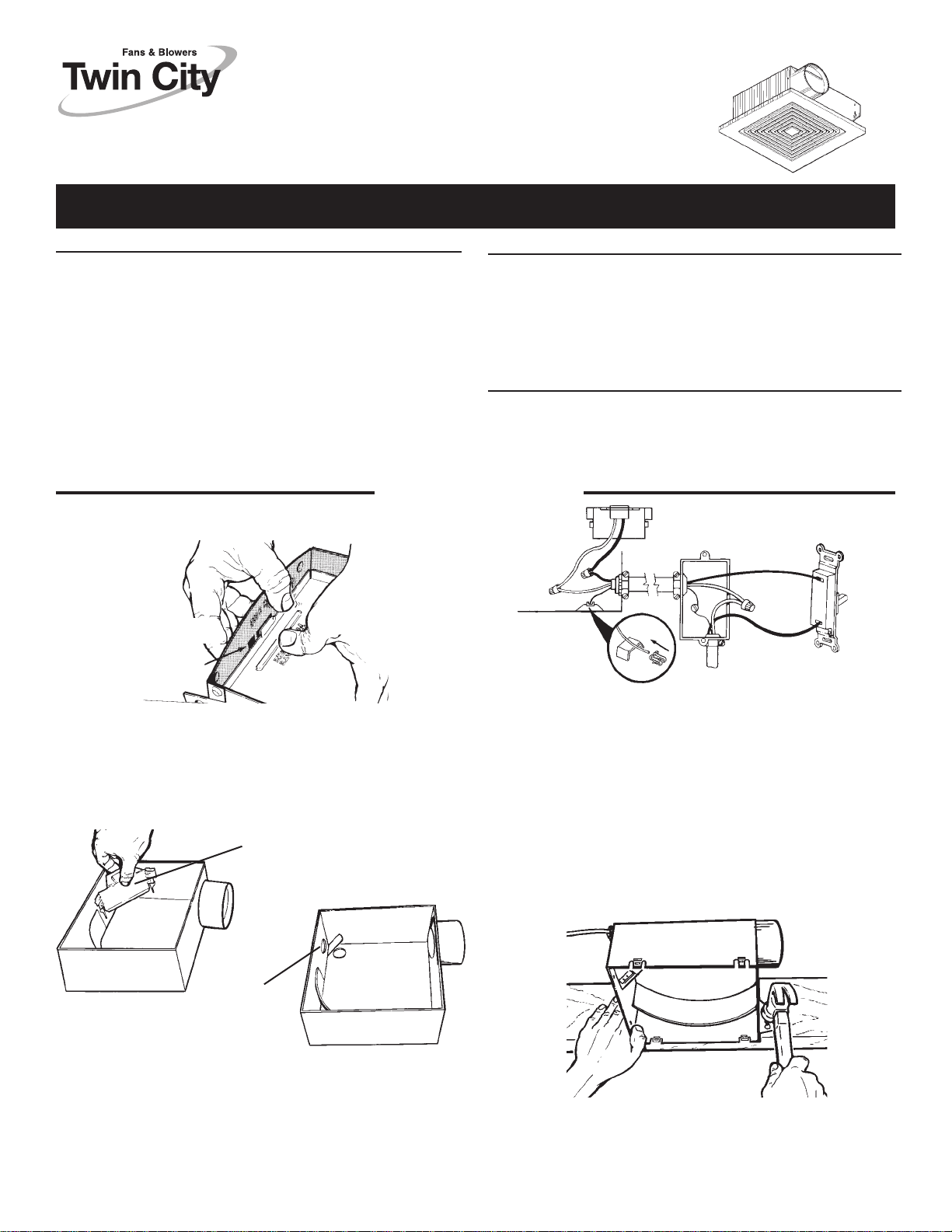

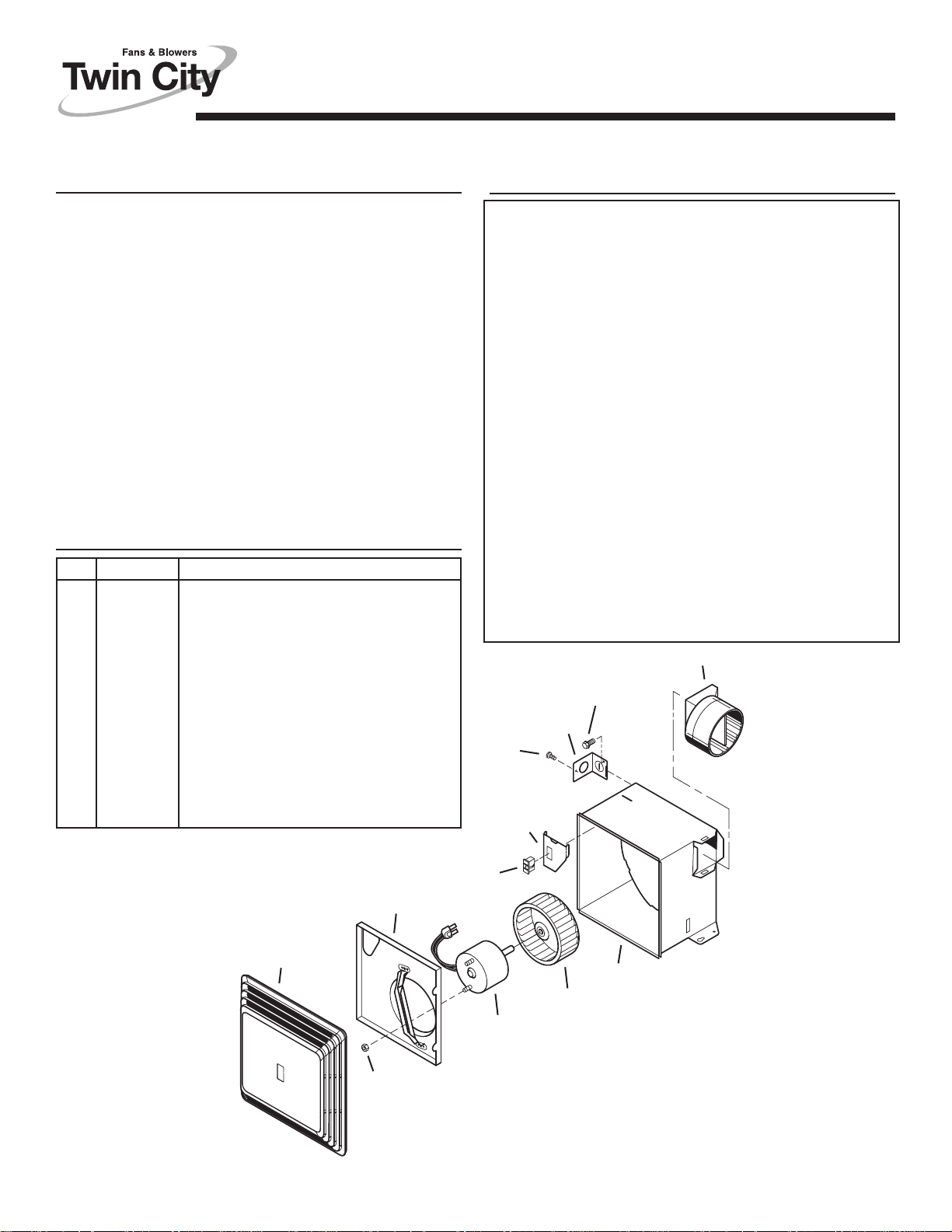

KEY PART NO. DESCRIPTION

1 97013576 Grille

2 97014926 Motor Plate

3 99080518 Motor (T080)

4 99020276 Impeller

5 99260425 Motor Nut (2 req.)

*97015159 Blower Assembly (includes Key Nos. 2 thru

5) (T080)

6 99270982 Receptacle

7 98009611 Wire Panel

*97015170 Wire Panel Assembly (includes Key Nos. 6 & 7)

8 97014922 Housing

9 97003932 Damper/Duct Connector

10 98008868 Wiring Plate

11 99150575 Screw, #8-18 x .375

12 99150574 Ground Screw

*Not shown assembled.

Order replacement parts by

“PART NO.” - not by “KEY NO.”

USE AND CARE

SERVICE PARTS

WARRANTY

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY AND

LOCK OUT SERVICE PANEL BEFORE CLEANING OR SERVIC-

ING THIS UNIT.

The motor is permanently lubricated. Do not oil or disassemble

motor.

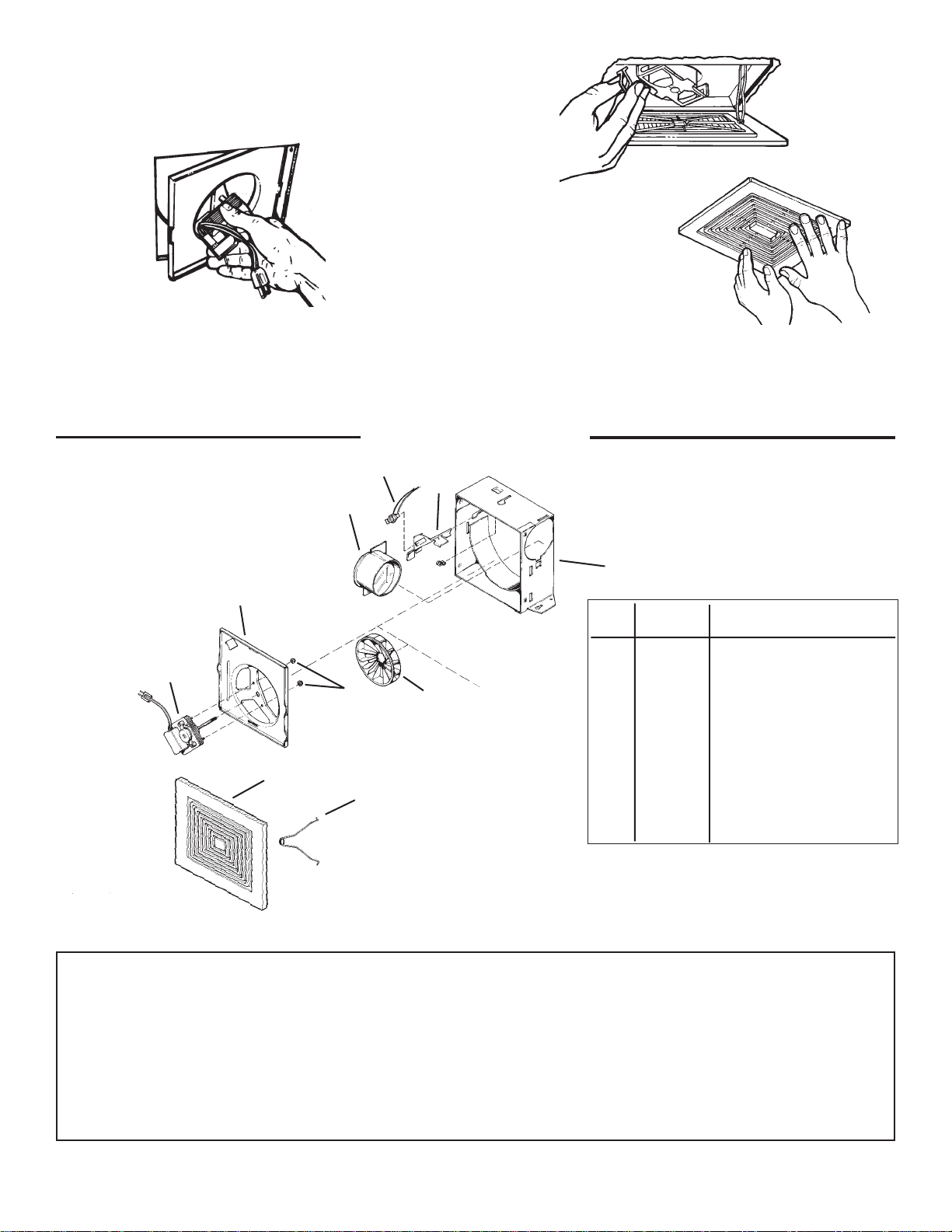

TO CLEAN GRILLE:

CAUTION: Plastic parts can be cleaned with mild, soapy water (use

a mild detergent, such as dishwashing liquid) and dried with a soft

cloth. Do not use abrasive cloth, steel wool pads, or scouring

powders.

TO CLEAN FAN ASSEMBLY:

Unplug fan assembly. To remove motor plate: Find the single tab on

the motor plate (located next to the receptacle). Push up near motor

plate tab while pushing out on side of housing. Or insert a straight-

blade screwdriver into slot in housing (next to tab) and twist

screwdriver. Gently vacuum fan, motor and interior of housing.

METAL AND ELECTRICAL PARTS SHOULD NEVER BE IM-

MERSED IN WATER.

99042959B

Limitation of Warranties and Claims

Seller warrants to the original purchaser that the goods sold hereunder shall be

free from defects in workmanship and material under normal use and service

(except in those cases where the materials are supplied by the buyer) for a period

of one year from the date of original installation or eighteen (18) months from the

date of shipment, whichever occurs first. The liability of seller under this warranty

is limited to replacing, repairing, or issuing credit (at cost, F.O.B. factory and at

seller’s discretion) for any part or parts which are returned by buyer during such

period provided that:

a. seller is notified in writing within ten (10) days following discovery of such de-

fects by buyer, or within ten (10) days after such defects should reasonably have

been discovered, whichever is less;

b. the defective unit is returned to seller, transportation charges prepaid by buyer.

c. payment in full has been received by seller or said products; and

d. seller’s examination of such unit shall disclose to its satisfaction that such de-

fects have not been caused by misuse, neglect, improper installation, repair, alter-

ation, act of God, or accident.

No warranty made hereunder shall extend to any seller product whose serial num-

ber is altered, effaced or removed. Seller makes no warranty, express or implied,

with respect to motors, switches, controls, or other components of seller’s prod-

uct, where such components are warranted separately by their respective manu-

facturers. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WAR-

RANTIES, EXPRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. In no event shall seller be liable to buyer for

indirect, incidental collateral, or consequential damages of any kind. (BUYER’S

FAILURE TO PAY THE FULL AMOUNT DUE WITHIN SIXTY (60) DAYS OF DATE

OF INVOICE SHALL OPERATE TO RELEASE SELLER FROM ANY AND ALL

LIABILITY OR OBLIGATION ARISING PURSUANT TO ANY WARRANTY, EX-

PRESS OR IMPLIED, WHETHER STATUTORY OR OTHERWISE, INCLUDING

ANY IMPLIED WARRANTY OR MERCHANTABILITY OR FITNESS FOR A PAR-

TICULAR PURPOSE, MADE IN CONNECTION WITH ANY CONTRACT FORMED

HEREUNDER. BUYER AGREES THAT SUCH FAILURE TO PAY SHALL CON-

STITUTE A VOLUNTARY WAIVER OF ANY AND ALL SUCH WARRANTIES ARIS-

ING PURSUANT TO SUCH CONTACT.)

TWIN CITY FAN & BLOWER, 5959 Trenton Lane, Minneapolis, MN 55442

MODEL •T080