5

4 Personal safety

For your own personal safety and the safety of your surroundings, it is important that you

read and understand the user manual. It is the responsibility of the user to perfectly

understand the manual to ensure the correct use and safe operation of the machine.

If you feel uncertain as to the correct handling and use of the Contractor mini dumper, it is

important that you get in contact with the seller or Twinca A/S.

Warning A faulty maintenance could be risky. Read and understand the

sections before carrying out any kind of maintenance, service or

repair of the machine.

This machine is very heavy and should not be lifted without assistance. Get help

and use a suitable lifting appliance.

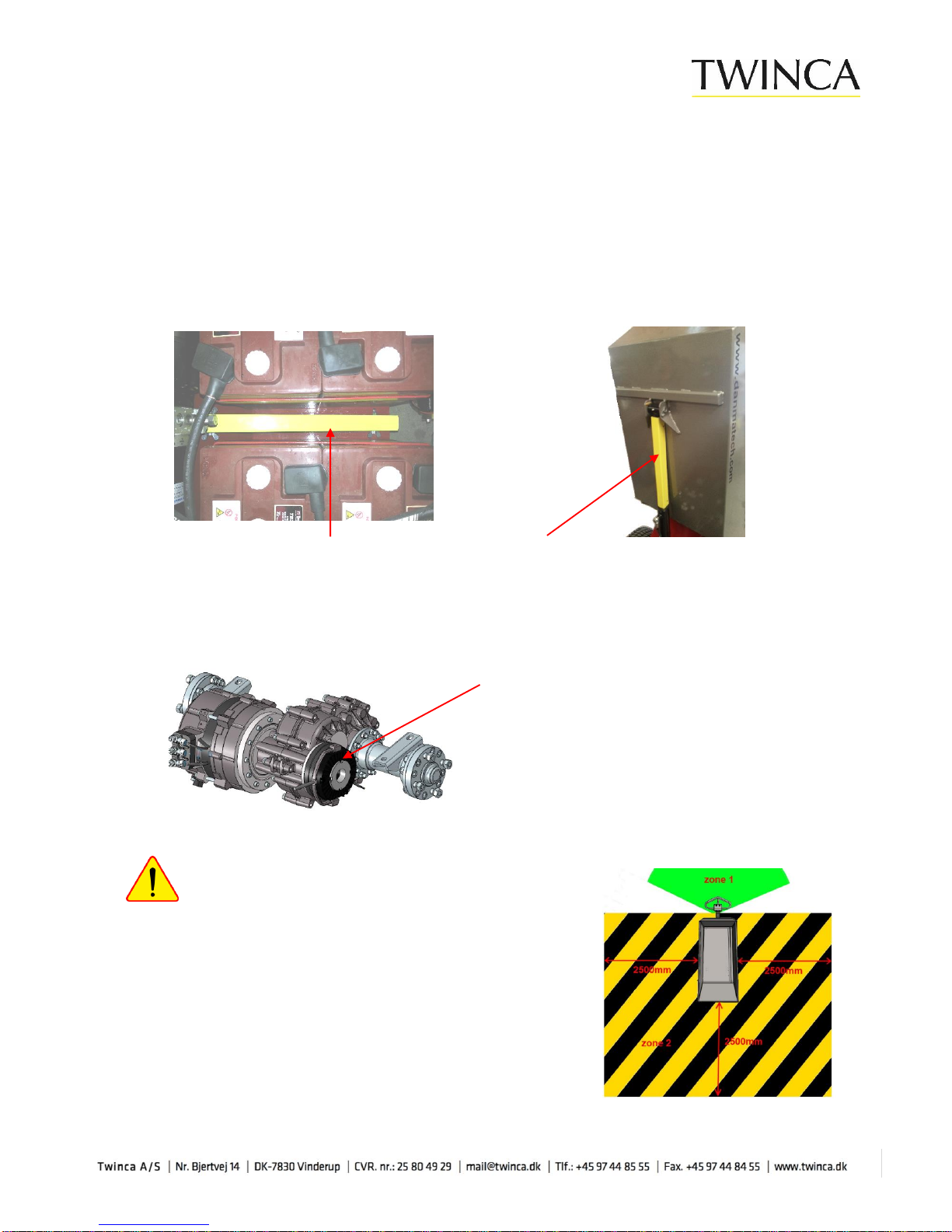

Keep the working area free and make sure that persons without affiliation to the

working process are at a safe distance from the machine and the working area.

The user should wear personal protective equipment when required.

Be sure that you know how to switch off the machine before you turn it on in case

you get into some kind of trouble during the operation of the machine

Always switch off the engine before transportation or servicing/repair of the

machine.

Never modify or remove safety devices, mounted in order to ensure your personal

safety. It is important that you check the correct functioning of the safety devices. If

such devices are defective or missing –DO NOT OPERATE THE CONTRACTOR

MINI DUMPER until the safety devices have been restored or repaired.

Do not operate the machine if you are ill, feel tired or under the influence of alcohol

or drugs.

Never stand on the machine at any time.

Do not use the Contractor mini dumper for transportation of people or animals.

Driving downhill should always be during reversing.

Walk carefully around the machine, as the dump bed has sharp edges.

Make sure that the dump bed is always in the lower position when you leave

the machine!

Personal protective equipment

When operating the machine, always wear suitable personal protective equipment such as

safety goggles, safety gloves, ear plugs, dust respirator and safety footwear. Wear the

personal protective equipment required for the operation to be made. Cover and protect

long hair and take off all pieces of jewellery, as they may stuck in the moving parts of the

machine.