General

Introduction ................................................................ 1-1

Design Highlights ....................................................... 1-1

Specifications ............................................................. 1-1

FCC Requirements....................................................... 1-2

Canadian Emissions Requirements ............................. 1-3

Warranty ..................................................................... 1-3

Ordering Numbers ...................................................... 1-4

TxPORT Customer Service ........................................ 1-4

Installation

Introduction ................................................................ 2-1

Site Preparation .......................................................... 2-1

Unpacking and Inspection .......................................... 2-1

Mounting ................................................................... 2-1

Wiring and Connections .............................................. 2-2

Chassis Ground Connection ................................. 2-2

DC Power Connection ......................................... 2-2

Alarm Connection ................................................ 2-2

T1 Connection ..................................................... 2-2

COM Bus Connection .......................................... 2-3

Configuration Modes ................................................... 2-3

Switch Configuration ........................................... 2-3

ROM Configuration ............................................. 2-4

RAM Configuration ............................................. 2-5

Manager Configuration ........................................ 2-5

Preservice Testing ....................................................... 2-5

Path A Preservice Testing .................................... 2-5

Path B Preservice Testing .................................... 2-6

Results .................................................................. 2-7

End-to-End Pre-Service Testing .......................... 2-7

Bypass Test ................................................................. 2-8

Operation

Introduction ................................................................. 3-1

Applications ................................................................ 3-1

General Operation ....................................................... 3-1

Revertive and Non-Revertive Switching ............. 3-1

Default Power-Up Path ........................................ 3-1

Loss of Signal / Loss of Frame ............................ 3-1

Bipolar Violations ................................................ 3-1

CSU Loopbacks ................................................... 3-2

Forced/Locked Capability ................................... 3-2

APS Switching Time ........................................... 3-3

APS Switching Parameters .................................. 3-3

Line Availability Timer ....................................... 3-4

Status and Performance Information .................... 3-4

Configuration Modes ........................................... 3-4

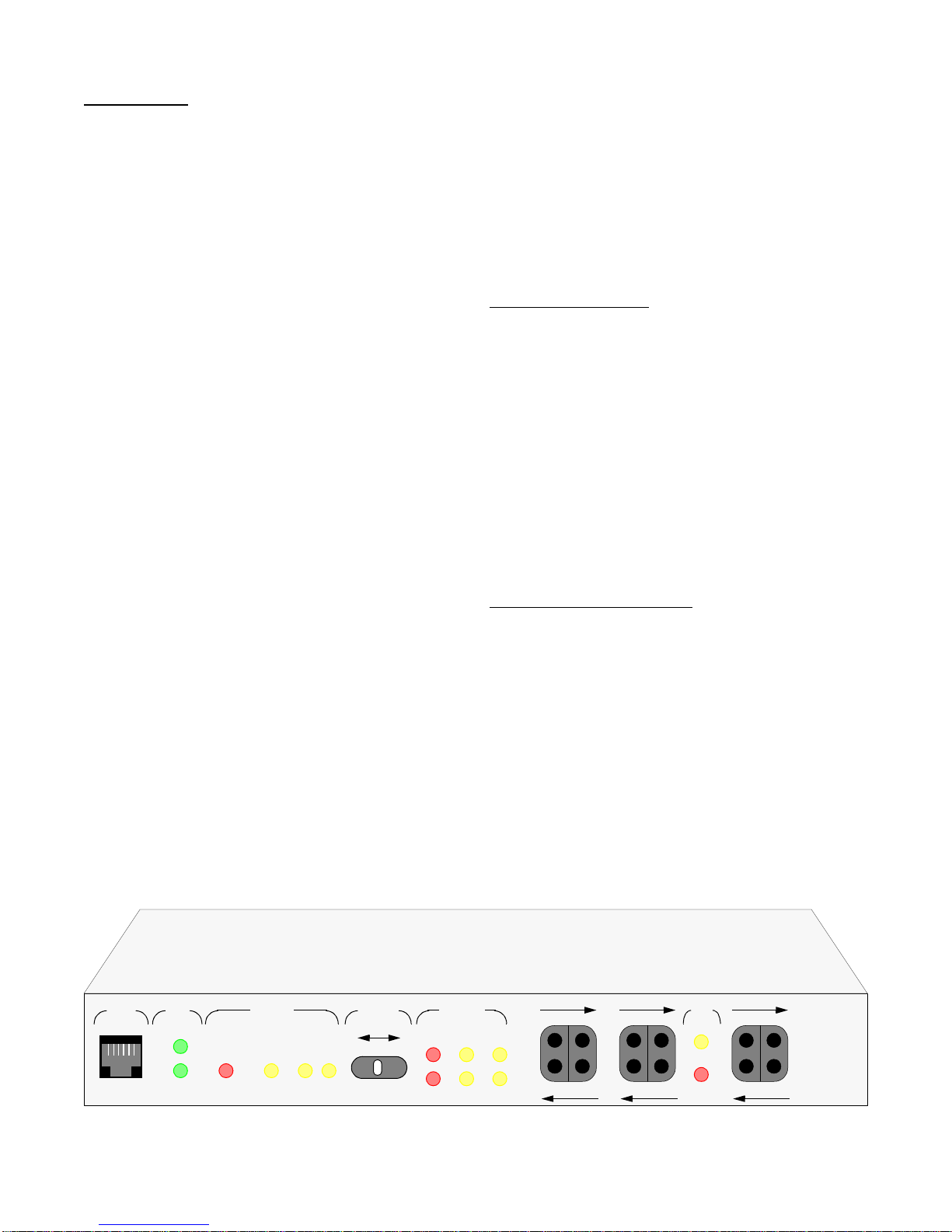

Front Panel Controls and Indicators ........................... 3-4

Supervisory Port .................................................. 3-4

Power Indicators .................................................. 3-5

Bypass Indicator .................................................. 3-5

Locked Indicator .................................................. 3-5

Status Indicators .................................................. 3-5

Manual Path Selector Switch ............................... 3-6

Path Status Alarm Indicators ............................... 3-6

Path Status LOS Indicators .................................. 3-6

Path Status Loop Indicators ................................. 3-6

Bantam Test Access Jacks ................................... 3-6

DTE Loop Indicator ............................................ 3-6

DTE Loss of Signal Indicator .............................. 3-6

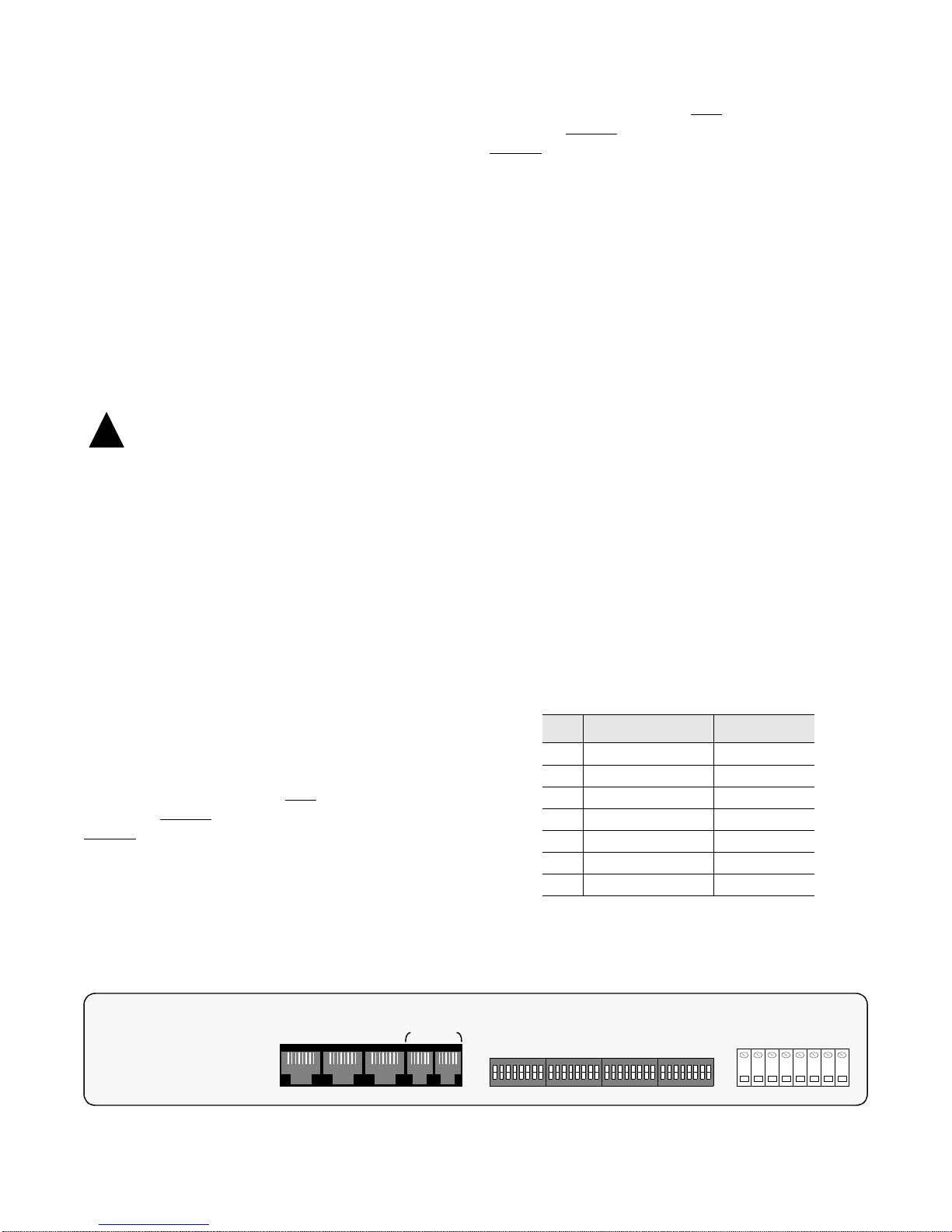

Rear Panel Connections .............................................. 3-7

COM Bus Connections ........................................ 3-7

Network T1 Connections ..................................... 3-7

DTE T1 Connection ............................................ 3-7

Screw Terminal Connections ............................... 3-7

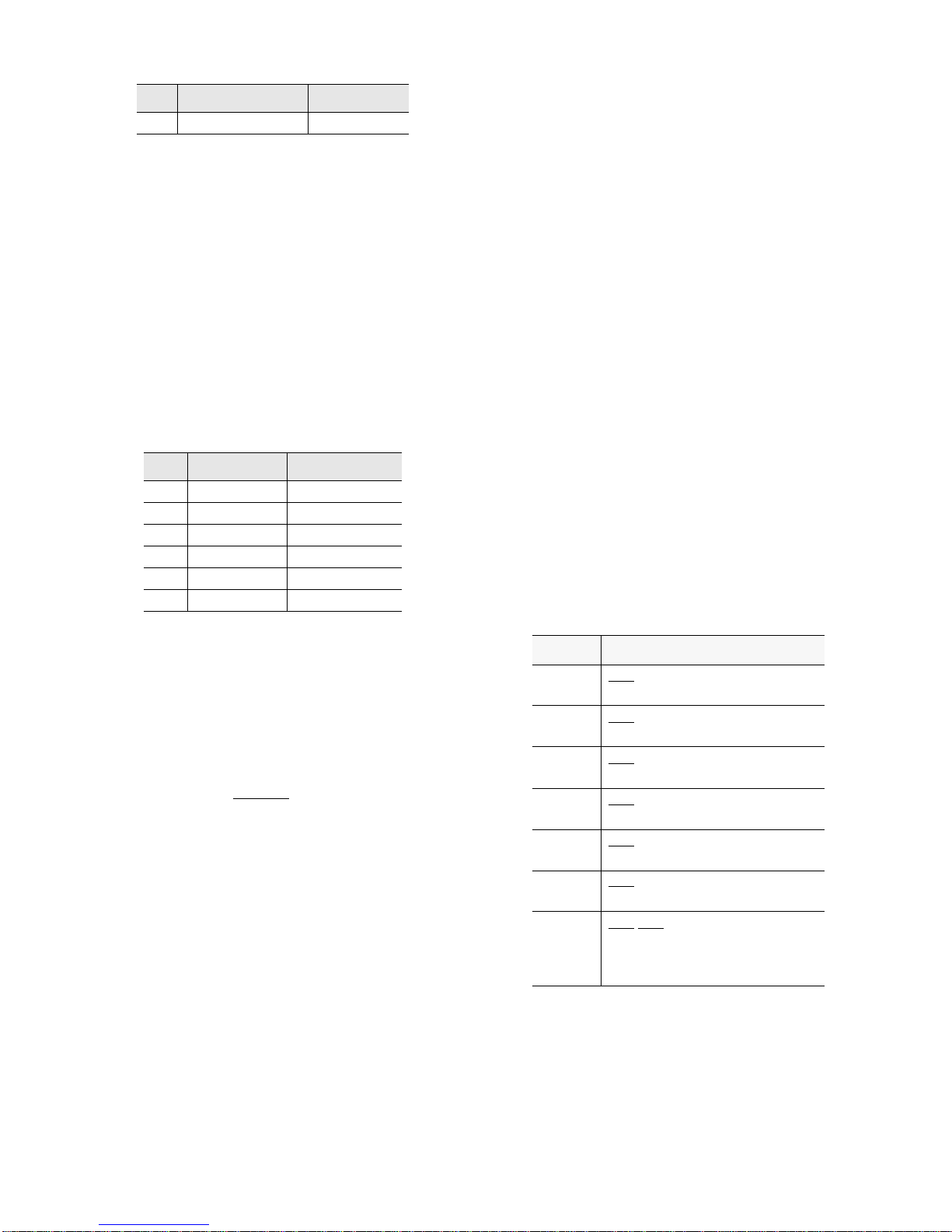

Option Switch Functions ............................................ 3-8

LAPS Operation

Introduction ................................................................. 4-1

LAPS Installation ....................................................... 4-1

Screens and Menus ..................................................... 4-1

Common Screen Elements ................................... 4-1

Cursor Controls .................................................... 4-2

User Log On ........................................................ 4-2

Main Menu Screen ...................................................... 4-2

Circuit List Screens ..................................................... 4-3

Circuits in Alarm Screen ..................................... 4-3

Circuits in Test Screen ......................................... 4-3

Circuit List Screen ............................................... 4-3

Screen Manipulation ............................................ 4-3

Performance Screen ............................................. 4-4

Maintenance Screen .................................................... 4-6

Configuration Screen .................................................. 4-7

Utilities Screens .......................................................... 4-9

Loopback Operations .................................................. 4-10

Near CO Payload Loop ........................................ 4-10

CO Line Loop ...................................................... 4-10

CO Facility Loop ................................................. 4-11

CO Equipment Loop ............................................ 4-12

CPE Payload ........................................................ 4-12

CPE Line .............................................................. 4-12

CSU Loop ............................................................ 4-13

NET Loop ............................................................ 4-13

NPC Payload Loop .............................................. 4-13

BERT Testing ............................................................. 4-14

Table of Contents