LT0181 Page 4 Issue 3.1

Fault Finding

If any Circuit Alarm LED goes on, check that circuit’s wiring and detectors, EOL, etc.

If no Circuit Alarm LED is on, turn the Silence Alarms switch to normal. If there are no other faults,

the Defect LED will go out, and the Normal LED come on. If not, check the Defect LEDs flashes to

identify the type of fault (see Defect under Operation).

Operation

Indicators

Normal -

On steady with 0.5 second pulse, “winking” off every 8 seconds: mains on.

On steady with 0.5 second pulse, “winking” off every 2 seconds: battery test in progress.

Off, winking on every 4 seconds: mains off.

Off steady: the panel is in defect, or alarm, or alarms are silenced, or non-latching test mode is on, or

detector gating/reset is in progress.

Defect - Gives a set of six flashes if a defect is present. These repeat after 2 seconds (mains on) or 25

seconds (mains off). Each flash represents a type of defect; a long flash means that a particular type of

defect is present. Historical information is also displayed in the same format if the NLT link/switch is

fitted/operated.

2nd = Battery Low / Disconnected or Fuse Blown

4th = Silence Alarms operated

Circuit Alarm - On steady: a detector on this circuit has operated. Winking on with the first defect flash

(when NLT is on): this circuit is in defect or has had a defect since the last Reset. Winking on the 5th

defect flash (with NLT on): Circuit is isolated (from Silence Alarms).

Buzzer - Single beep: a defect is present. Double beep: non-latching test mode is on. Continuous beeping:

the door is closed with the internal Silence Alarms switch on.

Controls

Silence Alarms keyswitch and internal switch - Either control prevents the alerting devices from

operating. A defect is shown while the keyswitch is operated. Internal Silence Alarms switch is interlocked

with the door. When the external Silence Alarms is operated, then restored to normal again, any alarmed

circuits will be isolated and a defect condition initiated. This will be shown by the Defect LED flashes (see

Defect under Operation above).

Evacuation keyswitch - Unconditionally operates the alerting devices.

Reset button - Clears latched (not current) alarm indications, circuit isolations, and historical defect

indications (hold for 1 second for best results).

NLT switch - Enables non-latched test mode if system is normal. Alerting devices operate for 1.5 seconds

(0.5 seconds if in “Legacy Mode”) when any detector operates, but Alarm indicators latch. Smoke detectors

are automatically reset on ALPHA 4. Also enables display of latched as well as current defects (Circuit

Alarm LEDs show which circuits have or have had defects).

Lamp Test - Operate both External and Internal Silence Alarm switches to illuminate all LEDs.

Regular Testing

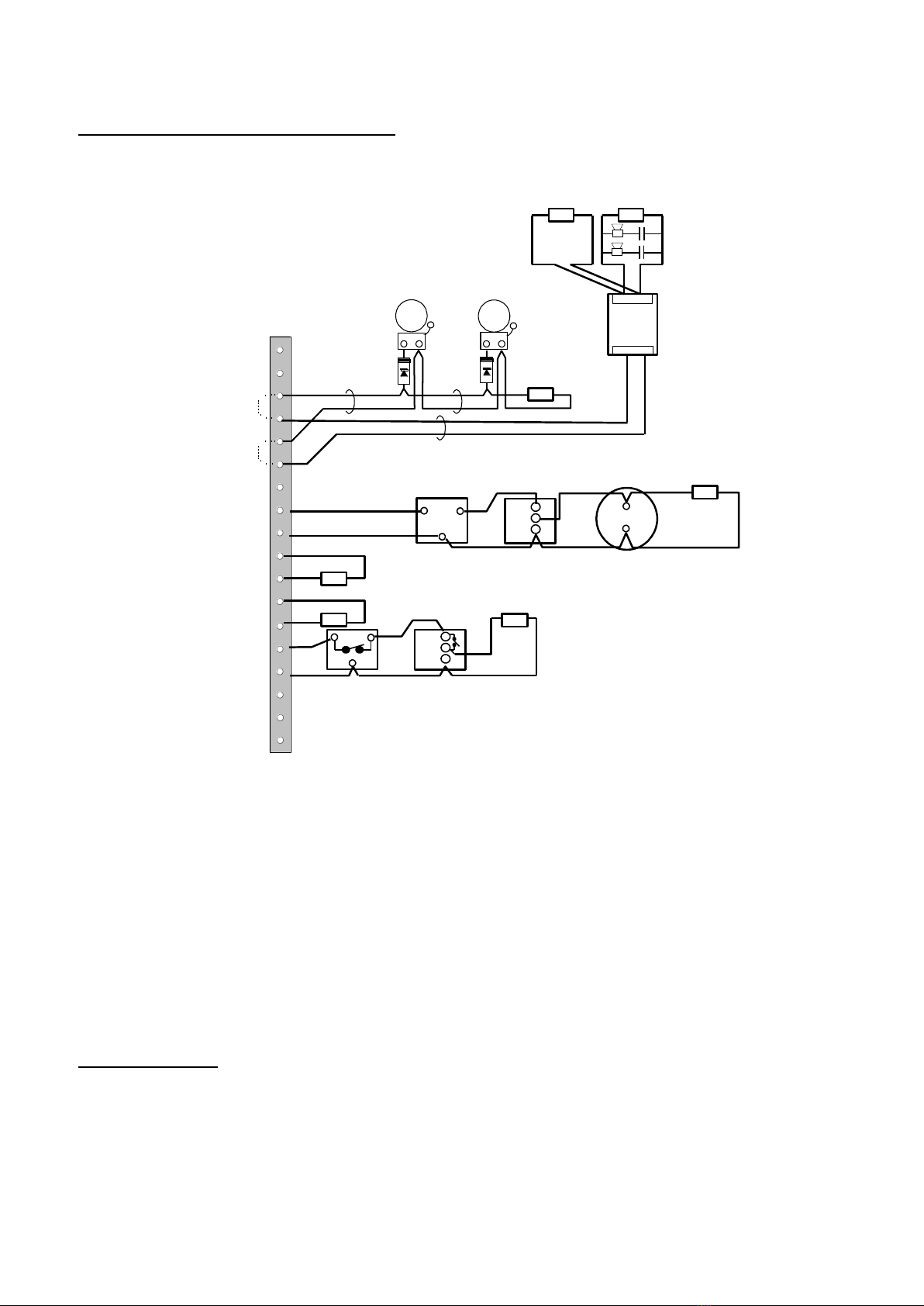

Use the FP0549 Test Probe to test the detector circuits and evacuation monitor (if enabled). Operate the

Silence Alarms control to prevent disturbance from the alerting devices when testing for alarm.

CONNECT CROCODILE CLIP TO

J16 (0V) or

Battery (-)ve

Circuit Alarm after ~9 seconds

gating delay

J15 (+VB) or

Battery (+)ve

Defect (or immediate Circuit alarm in

“Legacy mode”).

J16 (0V) or

Battery (-)ve

-WARNING -

NZS4512 and the NZ Building Code contain important requirements for the installation, commissioning, and

testing of fire alarm systems. You must comply with the requirements of these documents, and any other

statutory or regulatory requirements, in addition to the information contained in these instructions.

ALPHA 4 has no date functions, so is not affected by the “Year 2000” problem.