TFP351

Page 4 of 6

Step C. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

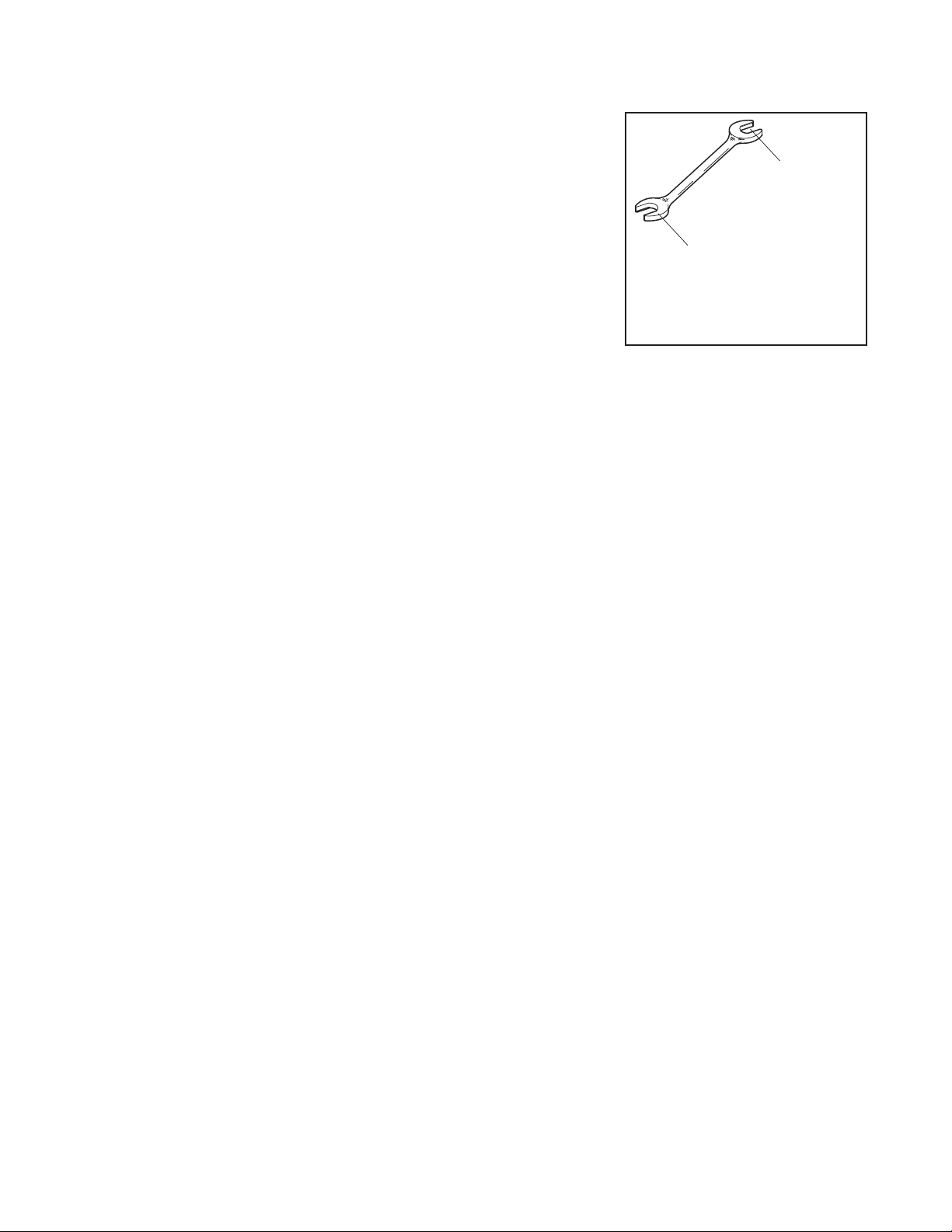

Step D. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

6 Sprinkler Wrench (refer to Figure 3).

With reference to Figure 1 or 2, the W-

Type 6 Sprinkler Wrench is to be ap-

plied to the wrench flats.

Step E. Rotate the S2 Shield clock-

wise (looking up) so that it slightly

compresses the O-Ring between the

Shield and sprinkler fitting.

Wax Coated Sprinklers

When installing wax coated sprinklers

with the adjustable Crescent wrench,

additional care needs to be exercised

to prevent damage to the wax coating

on the sprinkler wrench flats or frame

arms and, consequently, exposure of

bare metal to the corrosive environ-

ment. The jaws of the wrench should

be opened sufficiently wide to pass

over the wrench flats without damag-

ing the wax coating. Before wrench

tightening the sprinkler, the jaws of the

wrench are to be adjusted to just con-

tact the sprinkler wrenching flanges.

After wrench tightening the sprinkler,

loosen the wrench jaws before remov-

ing the wrench.

After installation, the sprinkler wrench

flats and frame arms must be inspect-

ed and the wax coating retouched (re-

paired) whenever the coating has been

damaged and bare metal is exposed.

The wax coating on the wrench flats

can be retouched by gently applying a

heated 1/8 inch diameter steel rod to

the areas of wax that have been dam-

aged, to smooth it back over areas

where bare metal is exposed.

NOTES

Only retouching of the wax coating

applied to the wrench flats and frame

arms is permitted, and the retouching

is to be performed only at the time of

the initial sprinkler installation.

The steel rod should be heated only to

the point at which it can begin to melt

the wax, and appropriate precautions

need to be taken, when handling the

heated rod, in order to prevent the in-

staller from being burned.

If attempts to retouch the wax coat-

ing with complete coverage are un-

successful, additional wax can be or-

dered in the form of a wax stick (the

end of which is color coded). Only

Installation

The Series TY-B, Upright and Pendent

Intermediate Level Sprinklers must

be installed in accordance with this

section.

General Instructions

Do not install any bulb type sprin-

kler if the bulb is cracked or there is

a loss of liquid from the bulb. With the

sprinkler held horizontally, a small air

bubble should be present. The diam-

eter of the air bubble is approximately

1/16 inch (1,6 mm) for the 135°F (57°C)

to 3/32 inch (2,4 mm) for the 360°F

(182°C) temperature ratings.

A leak tight 1/2 inch NPT sprinkler

joint should be obtained with a torque

of 7 to 14 ft.-lbs. (9,5 to 19,0 Nm). A

leak tight 3/4 inch NPT sprinkler joint

should be obtained with a torque of 10

to 20 ft.-lbs. (13,4 to 26,8 Nm). Higher

levels of torque may distort the sprin-

kler inlet and cause leakage or impair-

ment of the sprinkler.

Upright Sprinklers

The Series TY-B Intermediate Level

Upright Sprinklers must be installed

in accordance with the following

instructions.

Step 1. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

Step 2. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

6 Sprinkler Wrench (refer to Figure 3),

except that an 8 or 10 inch adjust-

able Crescent wrench is to be used for

wax coated sprinklers. With reference

to Figure 1 or 2, the W-Type 6 Sprin-

kler Wrench or the Crescent wrench,

as applicable, is to be applied to the

wrench flats.

Pendent Sprinklers

The Series TY-B Intermediate Level

Pendent Sprinklers must be installed

in accordance with the following

instructions.

Step A. Thread the S2 Shield onto the

sprinkler threads with the stamped

markings toward the deflector and

just to the end of the threads. The fi-

nal assembly step is easier to accom-

plish if the Shield is not disengaged by

continuing to turn the Shield past the

threads.

Step B. Roll the O-Ring over the

sprinkler threads until it seats against

the Shield.

the correct color coded wax is to be

used, and retouching of wrench flats

and frame arms is only permitted at

the time of initial sprinkler installation.

With the steel rod heated as previ-

ously described, touch the rod to the

area requiring additional wax with the

rod angled downward, and then touch

the wax stick to the rod approximately

one-half inch away from the area re-

quiring retouching. The wax will melt

and run down onto the sprinkler.

WRENCH RECESS

1/2" NPT MODELS)

WRENCH RECESS

(END "B" USED FOR

FIGURE 3

W-TYPE 6 SPRINKLER

WRENCH