N7DNL, NHD

INSTALLATION PROCEDURES

Carpentry Procedures

Case Pull-Up Locations

All the N7DNL and NHD models have four

pull-ups at each end of the case. Pull-ups A,

B, C and D are located as shown and should

be installed and tightened starting with A and

finishing with D.

NOTE

If extra pull-up bolts are needed, use the

bolts from the side shipping supports.

See “General-UL/NSF I&S Manual” for

line-up assembly instructions.

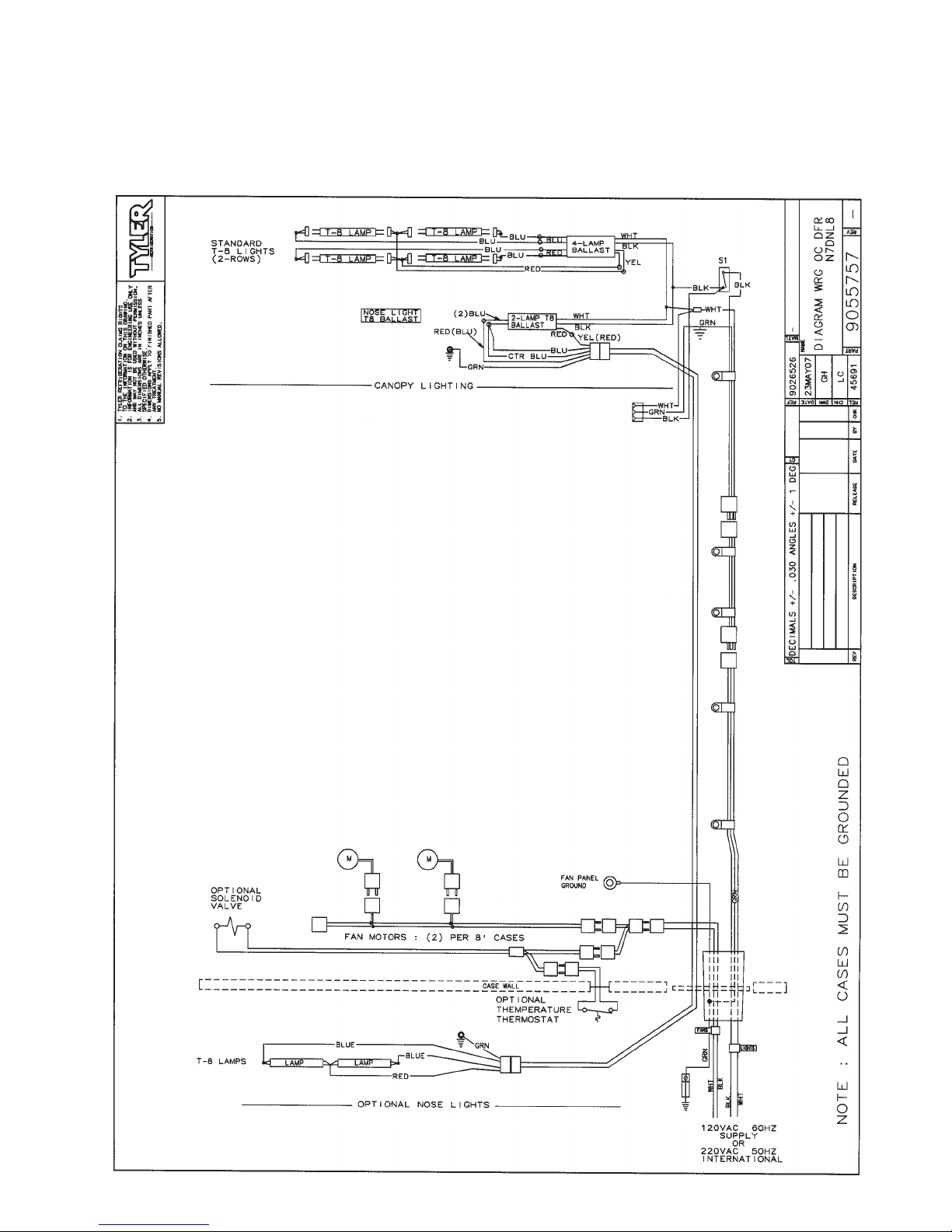

Electrical Procedures

Electrical Considerations

CAUTION

Make sure all electrical connections at

components and terminal blocks are tight.

This will prevent burning of electrical

terminals and/or premature component

failure.

NOTE

Raceway covers will be shipped loose.

See the “General-UL/NSF I&S Manual” for

raceway cover installation and removal

instructions.

Case Fan Circuit

This circuit is to be supplied by an uninter-

rupted, protected 120V circuit. The case fan

circuit is not cycled, except when equipped

for gas defrost (NHD models only). On gas

defrost cases the fans circuit is controlled by

a klixon.

Fluorescent Lamp Circuit

The standard lighting for N7DNL and NHD

cases is 2 rows of T-8 canopy lights. Optional

T-8 Nose Light is available on all models,

while T-8 shelf lighting is only available on

the NHD models.

Defrost Information

See “General-UL/NSF I&S Manual” for

operational descriptions for each type of

defrost control.

Defrost Control Charts

N7DNL Models

Defrost

Defrost Defrosts Duration Term.

Type Per Day (Min) Temp.

Off Time 6 19 ------

The N7DNL cases do not have any klixons.

NHD Models

Defrost

Defrost Defrosts Duration Term.

Type Per Day (Min) Temp.

Off Time 4 24 ------

Electric 4 24 41°F

Gas 4 15 55°F

Most klixons are located on the right end of

the evaporator coil.

NOTE

The Gas Defrost Termination klixon is

located at the by-pass check valve.

CAUTION

If electronic sensors are used in place of

the klixons, the sensors must be located in

the same location as the klixons for that

defrost type. Any other locations will

effect the refrigeration efficiency of the

case.

June, 2007Page 8