MAINTENANCE

INSTRUCTIONS

INTRODUCTION

All

U.S.

BLIND

STITCH

machines

are

designed

for

long

life

and

trouble-free

performance.

When

installed

and

lubricated

in

accordance

with

the

INSTALLATION

AND

OPERATING

INSTRUCTIONS,

only

the

minimum

maintenance

normally

associated

with

industrial

sewing

machines

will

be

required.

These

maintenance

requirements

will

generally

be confined

to

the

four

locations

described below,

at

which wear

may

be expected

after

extended

use.

When

such wear does

occur,

the

worn

part

may

be

readily

replaced

by

following

the

appropriate

instructions.

For ease

of

installation,

and

to

insure

satisfactory

service,

it

is

essential

that

only

genuine U.S.

BLIND

STITCH

parts

and needles are used.

They

are the only

parts

designed

specifically

for the machine, with the

built-in

long

life

and

ex

cellent

wearing

characteristics

typical

of

the

U.S.

BLIND

STITCH

machine.

A.

REPLACING

THE

LOOPER

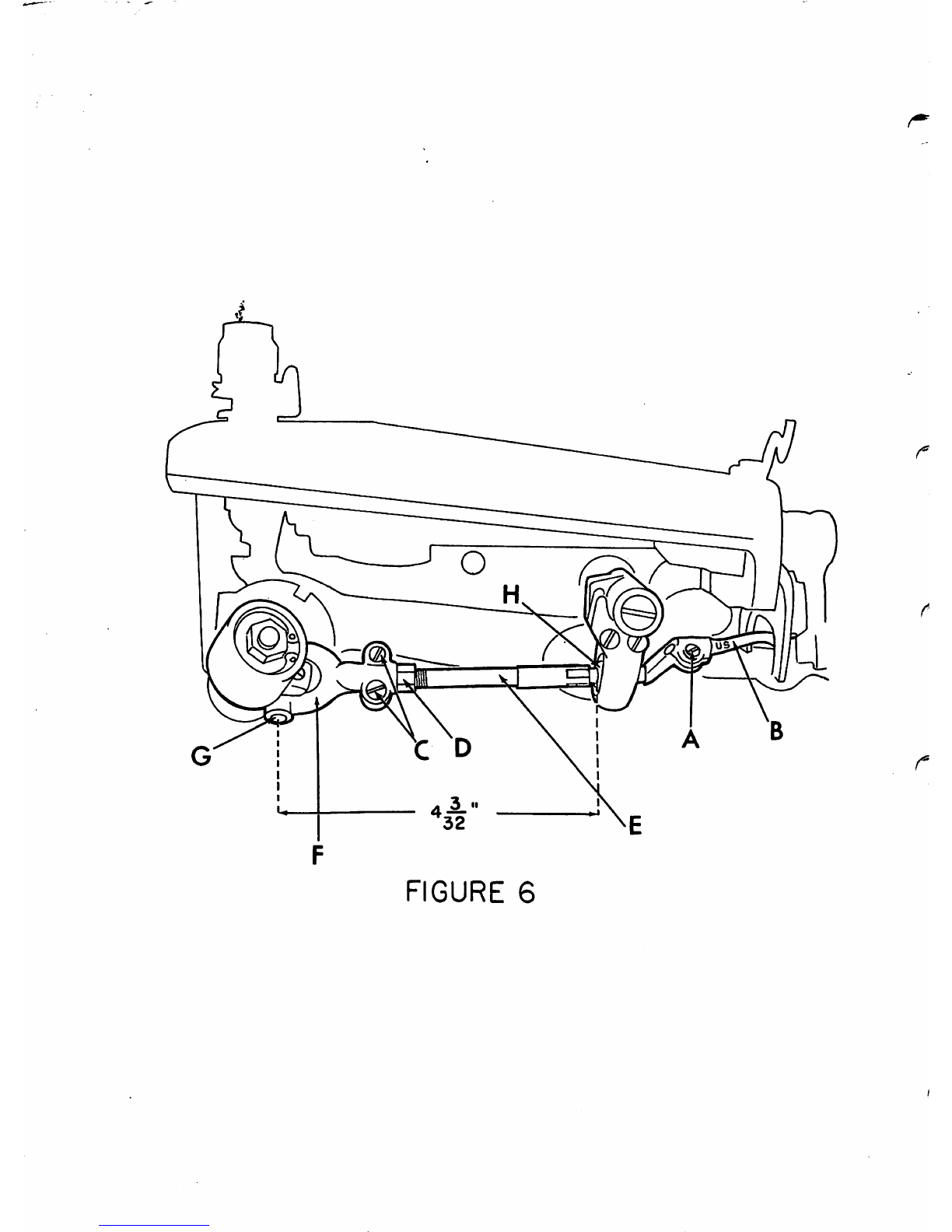

1.

Should

it

become

necessary

to

replace

the

looper

(item

"B"

in

Figure

6),

loosen

the

looper

clamp

screw

(item

"A"

in

Figure

6) and remove

the

old

looper.

Because

of

the

precise

fit

of

the

looper

in

the

looper

rod

it

may

be necessary to

exert

a moderate

amount

of

{

force

to

pull

the

looper

out.

Insert

the

new

looper

into

the

end

of

the

rod

as

far

as

it

will

go

before

bottoming

on

the

looper

shoulder.

r

2.

Any

time a looper

is

moved

or changed, recheck the looper

timing

and

reset

if

necessary. Proper looper timing

is

jJ

absolutely

essential

for

correct

stitch

formation.

As

described

in

detail

below,, a

properly

timed

looper

will

pass over the needle in the correct position to pick

up

the

loop, and

also

clear

the

chain-off

pin,

feeder,

looper

slot,

and

needle.

The

first

check

point for timing

the looper

is

at

the position

where

the looper picks the ^

thread loop

off

the needle during the needle

return

stroke.

u,

Referring

to

Figure 7, (Point "C"), the long prong of the

looper

should

pass

over

and

just

clear the scarf of the |

needle, approximately 3/32"

(2.4mm)

behind the

end

of the

c.

needle eye. At the

same

time, the short prong of the

looper should pass over the needle with about 1/64

(.406mm)

clearance,

and

must

be so

set

that

it

also

clears

the

chain-off

pin

(item

"D"

in

Figure

7).

• 'V>h' I

Si