−3 −

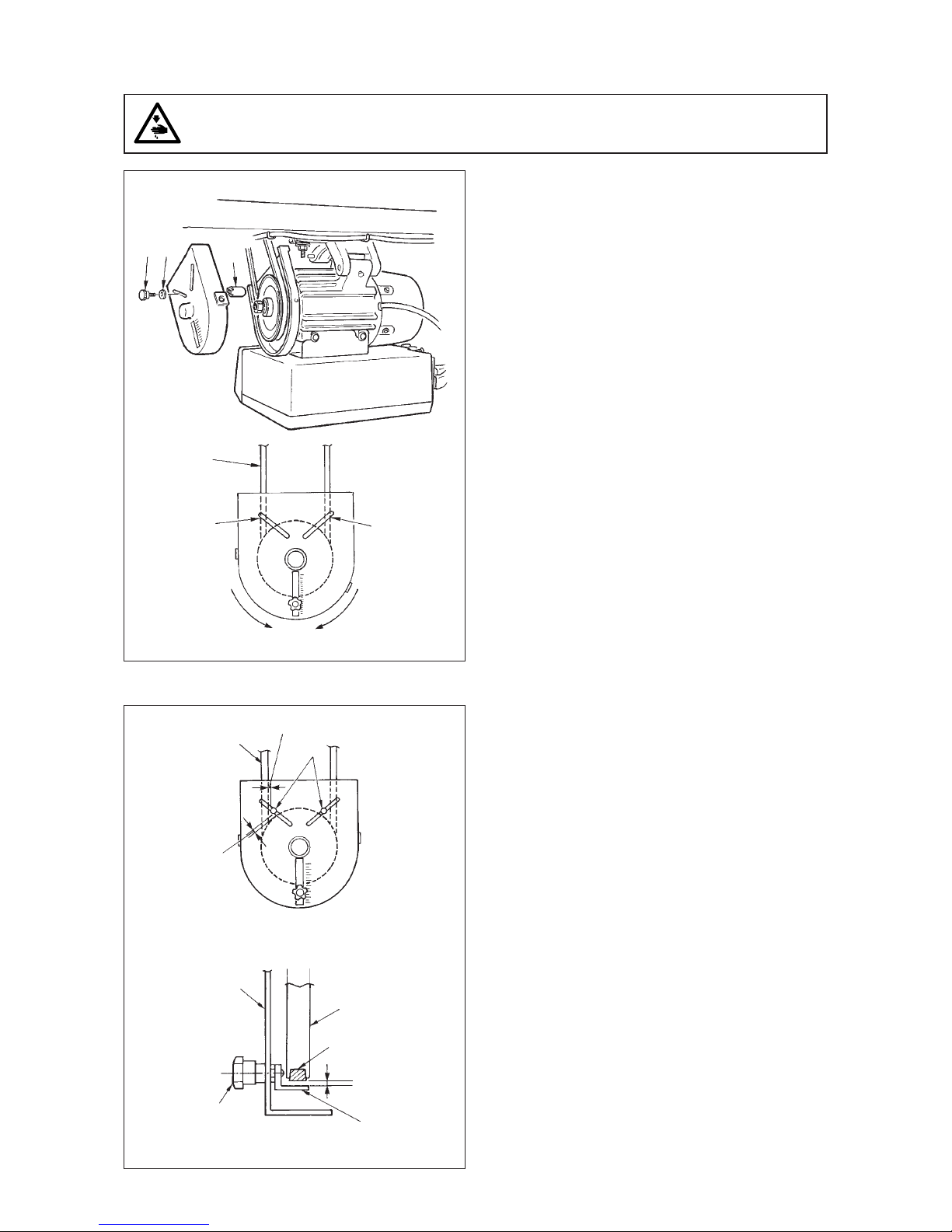

AB

Belt

1

23

4

5

1

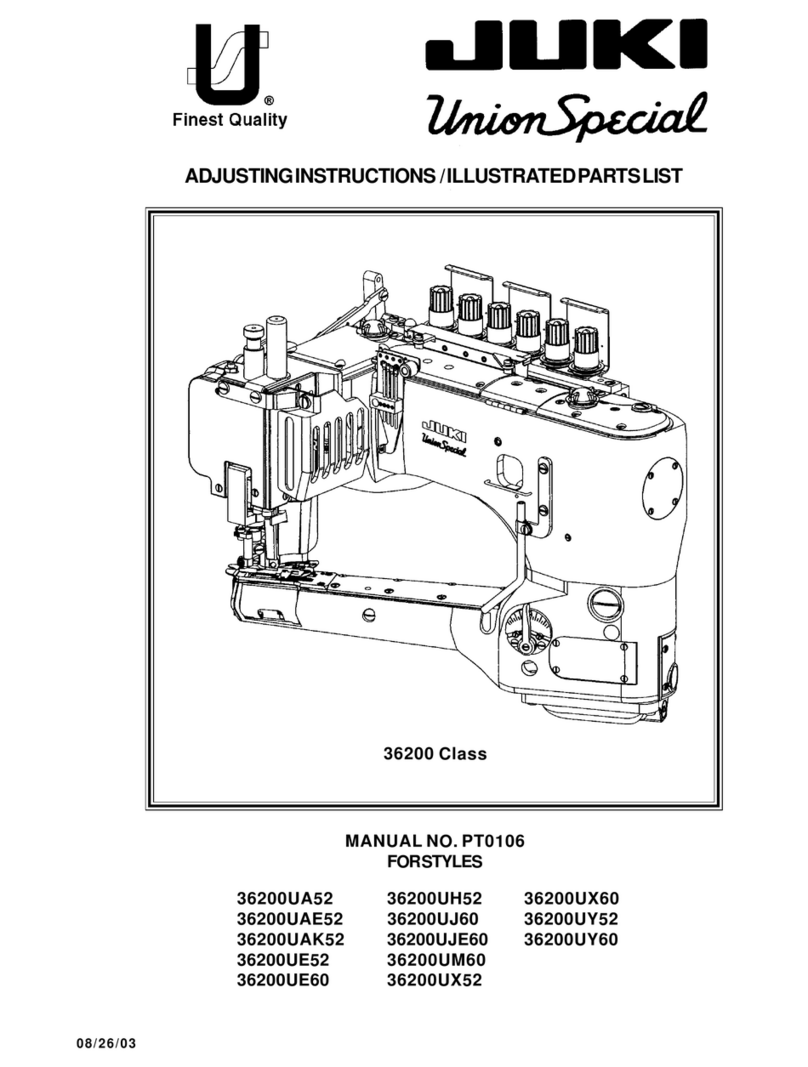

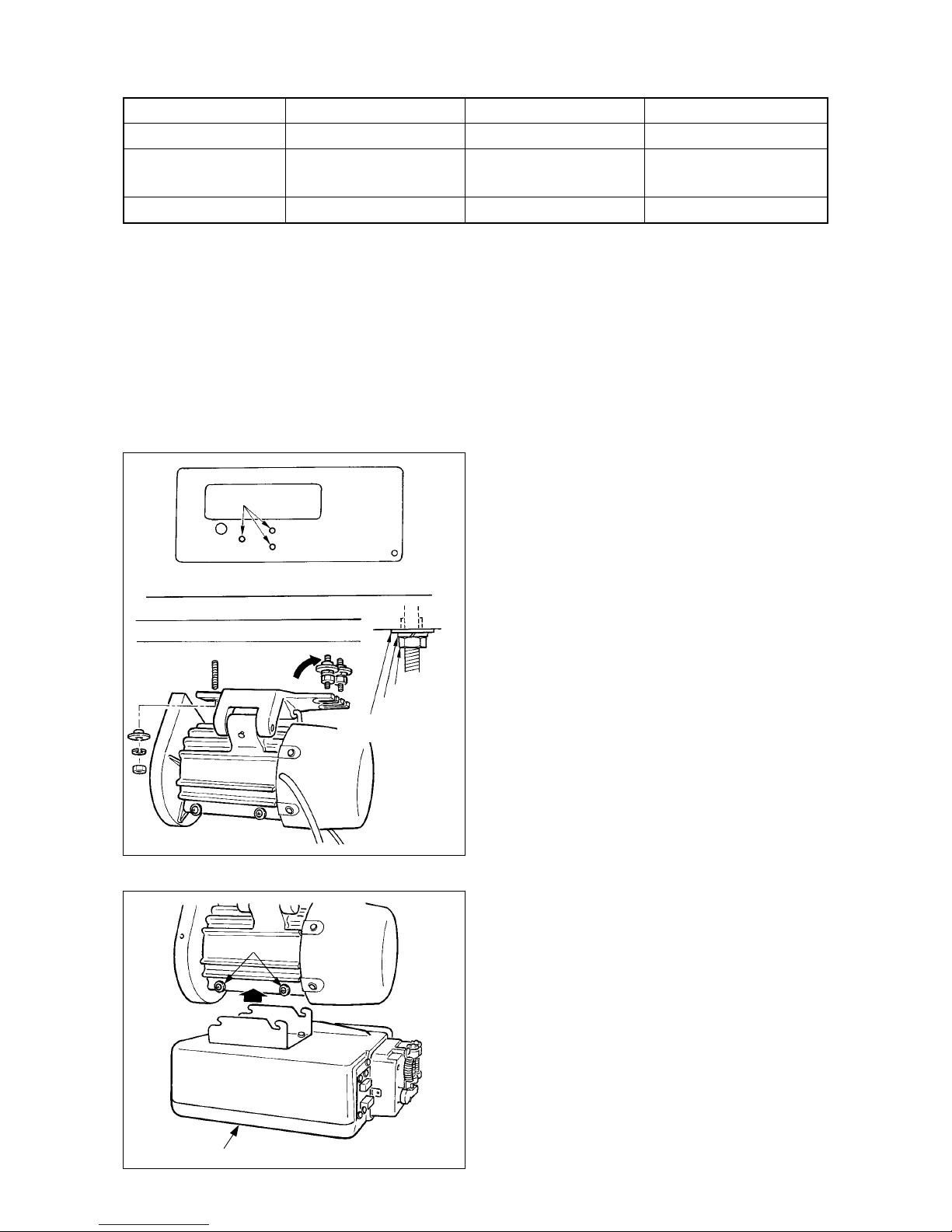

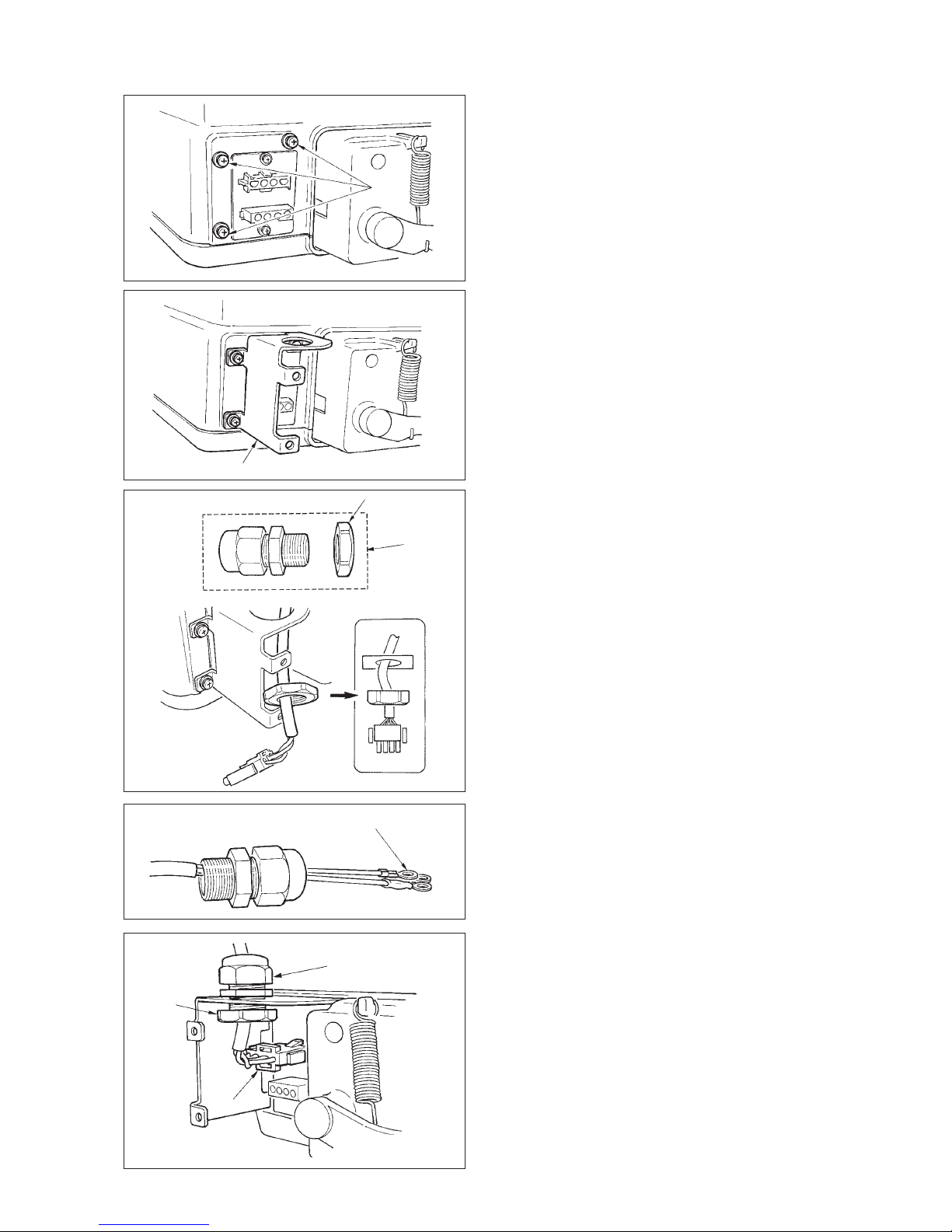

1) Attaching hole for the protecting pin

To attach protecting pin 1, select either attaching

hole Aor attaching hole Bin the motor pulley cover

in accordance with the direction of rotation of the

sewing machine and attach the pin in the selected

hole using screw 2and washer 3supplied with

the unit.

a) If the motor shaft rotates in direction A in the

figure on the above:

/Attach protecting pin 1in attaching hole A.

b) If the motor shaft rotates in direction B in the

figure on the above:

/Attach protecting pin 1in attaching hole B.

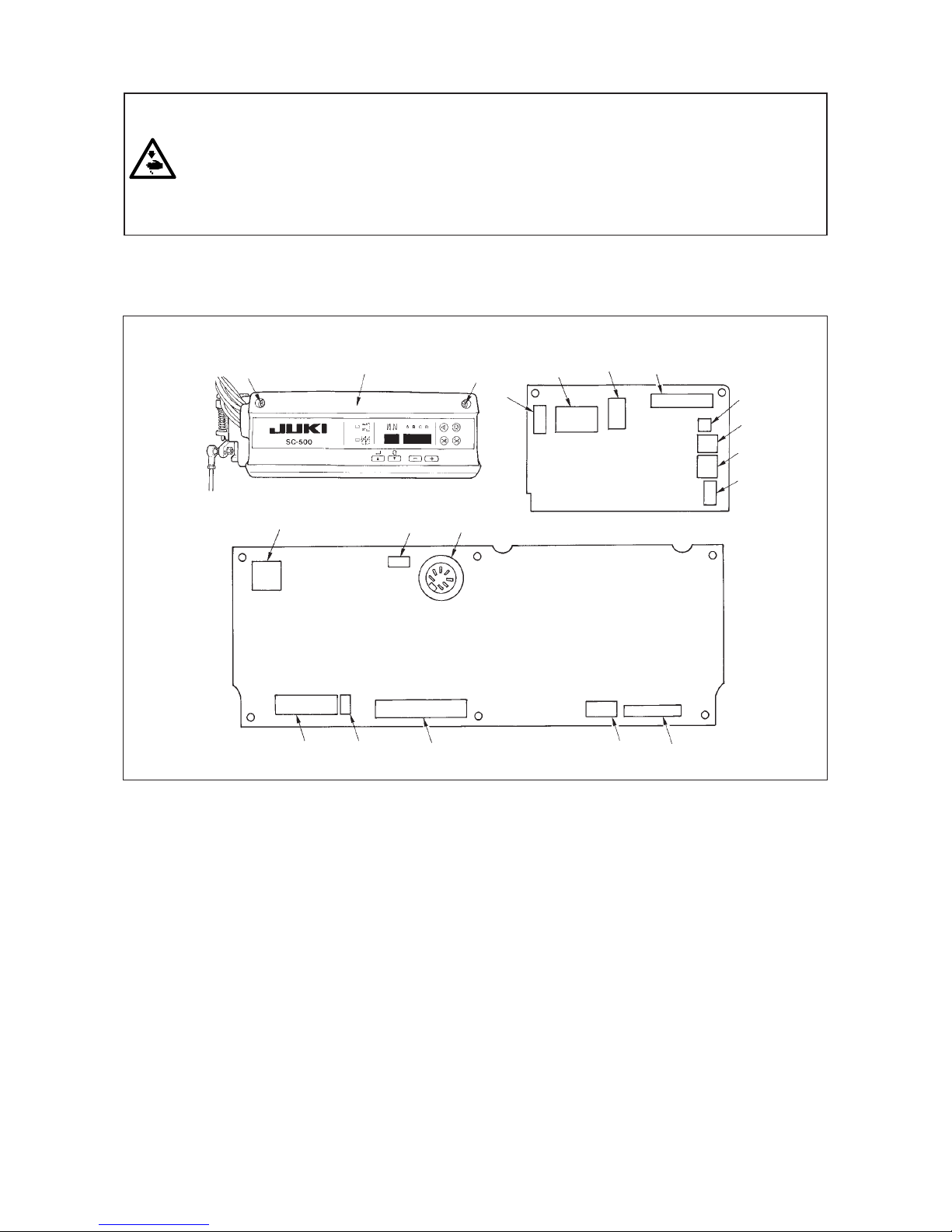

2) Adjustment for the protecting pin and the belt slip-

off preventing bracket

Adjust the position of protecting pin 1and belt slip-

off preventing bracket 4in accordance with the

figure on the left.

a) Adjusting the protecting pin

Loosen screw 2and adjust so that protecting

pin 1is positioned at the location indicated in

the figure on the left.

b) Adjusting belt slip-off preventing bracket

Loosen screw 5and adjust so that belt slip-

off preventing bracket 4is positioned at the

location indicated in the figure on the left.

If protecting pin 1is not properly adjusted, it

is possible that your fingers may be caught in

the clearance provided between the pulley and

the belt resulting in injury. If belt slip-off

preventing bracket 4is not properly adjusted,

it is possible to allow the belt to slip off causing

safety hazard.

3) After the adjustment, tighten screws 2and 5so

as to secure protecting pin 1and belt slip-off

preventing bracket 4to prevent these components

to fluctuate because of vibration.

4) Before starting the operation of the sewing

machine, ascertain that protecting pin 1and belt

slip-off preventing bracket 4do not come in contact

with the pulley and the belt.

5. Installation and adjustment for the protecting pin and the belt slip-off preventing bracket

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the

following work after turning the power off and ascertaining that the motor is at rest.

4 mm or less

Belt

4 mm or less

Adjusting position for protecting pin

Pulley

cover Motor

pulley

Belt

3 mm or less

Adjusting position for belt slip-off preventing braket

Attaching

hole A

Attaching

hole B