3. To adjust the looper so that the timing checks out as noted in paragraph 2,

it may be rotated within its clamp by a limited amount. This adjustment

should be made with the looper clamp screw (item

"A"

in Figure 6) loosened,

and the looper bottomed against its shoulder. Do

not

move the looper in or

out, and do

not

attempt

to force the looper

to

turn beyond the limited

amount

of

travel

available.

4.

If

the adjustment described in paragraph 3 is insufficient to provide

the

correct

timing, it willbe necessary to turn the looper rod (item

"E"

in Figure6) itself.

Thismay be accomplishedby looseningwith looper rod clamp screw (item

"C"

in Figure6). The rod is then free to turn in the looper rod fork (item

"D"

in

Figure 6). It will normally be necessary to make only a very small adjustment

in order to get the looper into the correct rotational position for proper timing.

If, for any reason,

the

rod has been removed

or

the

basic setting

of

the

looper

rod

has

been

disturbed

by

alarge

amount,

it

may

be

reset

by

noting

that

the

distance from

the

center

of

the

looper

rod

fork

pin (item

"F"

in Figure 6)

to

the rear face of the looper rod ball (item

"G"

in Figure 6) is normally 4 & 3/32

inches (104mm) (refer to Figure 6). If the rod is set to this dimension then only

minor

adjustment

will be required

to

bring

the

looper

into

the

correct

timing

position. Note

that

this dimension is merely a guide

to

assist in setting a rod and

variations

may

be

expected

from

machine

to

machine.

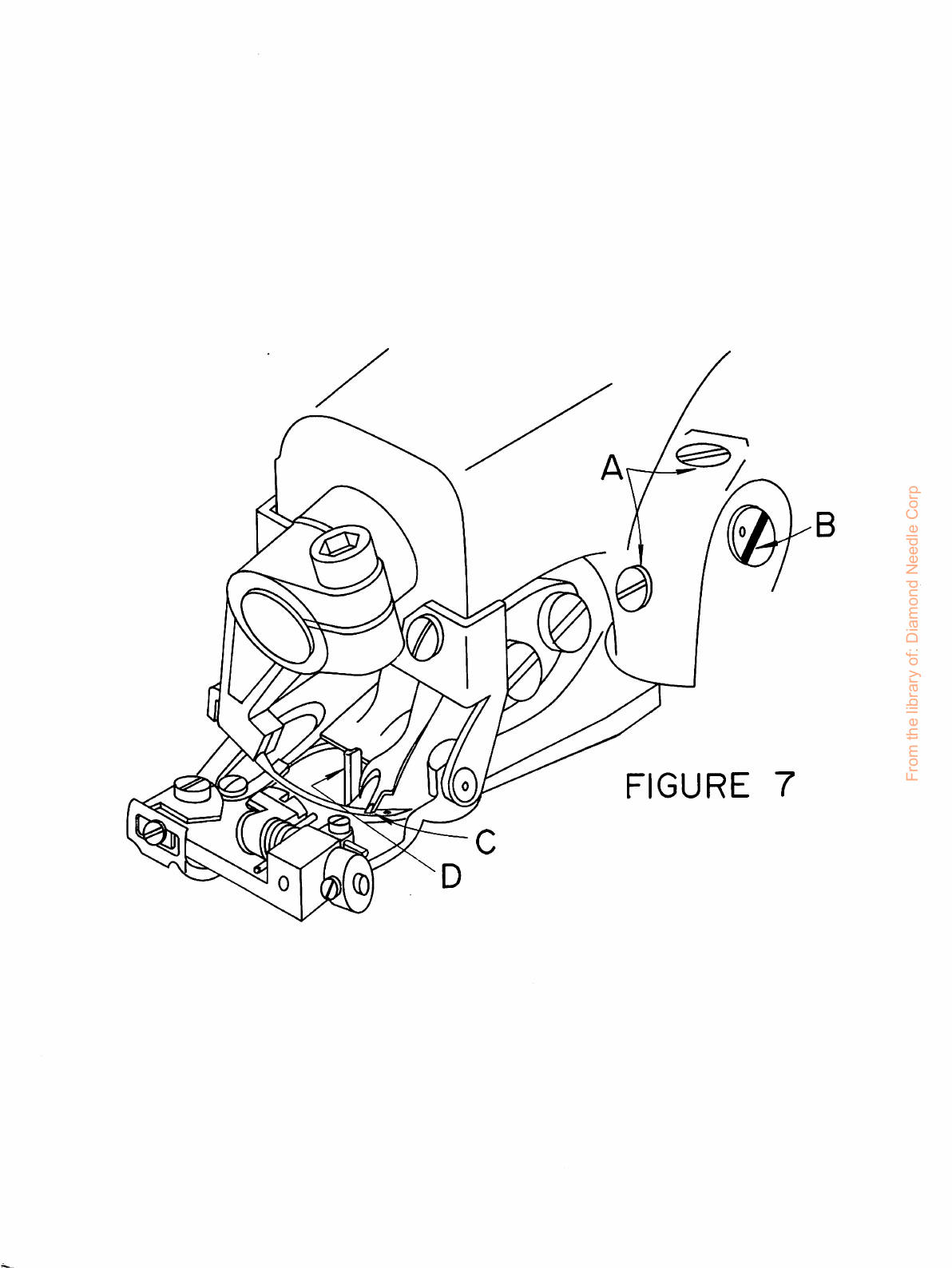

5. If, after completing the above adjustments, it is found

that

the looper is either

too

low or

too

high, it will be necessary

to

adjust

the

eccentric stud. First loosen

the

two

set

screws (item

"A"

in Figure 7). Place a wide blade screwdriver in

the

slot

of

the

eccentric

stud

(item

"B"

in Figure 7) and, using a slight turning

motion,

raise or lower the

looper

as required. Once

the

proper

height is established, check

to see whether the looper must be moved to the left or

to

the right prior to retight-

ening the eccentric block set screws. If such a movement is required, it may be ob

tained by lightly tapping the eccentric block in the correct direction with the

handle

of

a

screwdriver.

From the library of: Diamond Needle Corp