8.

Once

clearance

is

established

between

the

needle

and

the

looper

crotch,

continue turning the handwheel away from the operator until the needle

passes

between

thelooper

prongs,

clearing

both thelongand the short

prong.

If

difficulty

is

experienced

at thispoint,it

may

be

necessary

to

modify

some

of the

previous

adjustments to the eccentric blockor the looperrod

length.

If thisisdone,recheck the

previous

pointsto

insure

that a position isestab

lished which will satisfy all

of

the clearance conditions.

9. After

all

the

necessary

adjustments

have

been

made,

tighten

all

set

screws

and

the locknut and

recheck

allthe adjustment points.

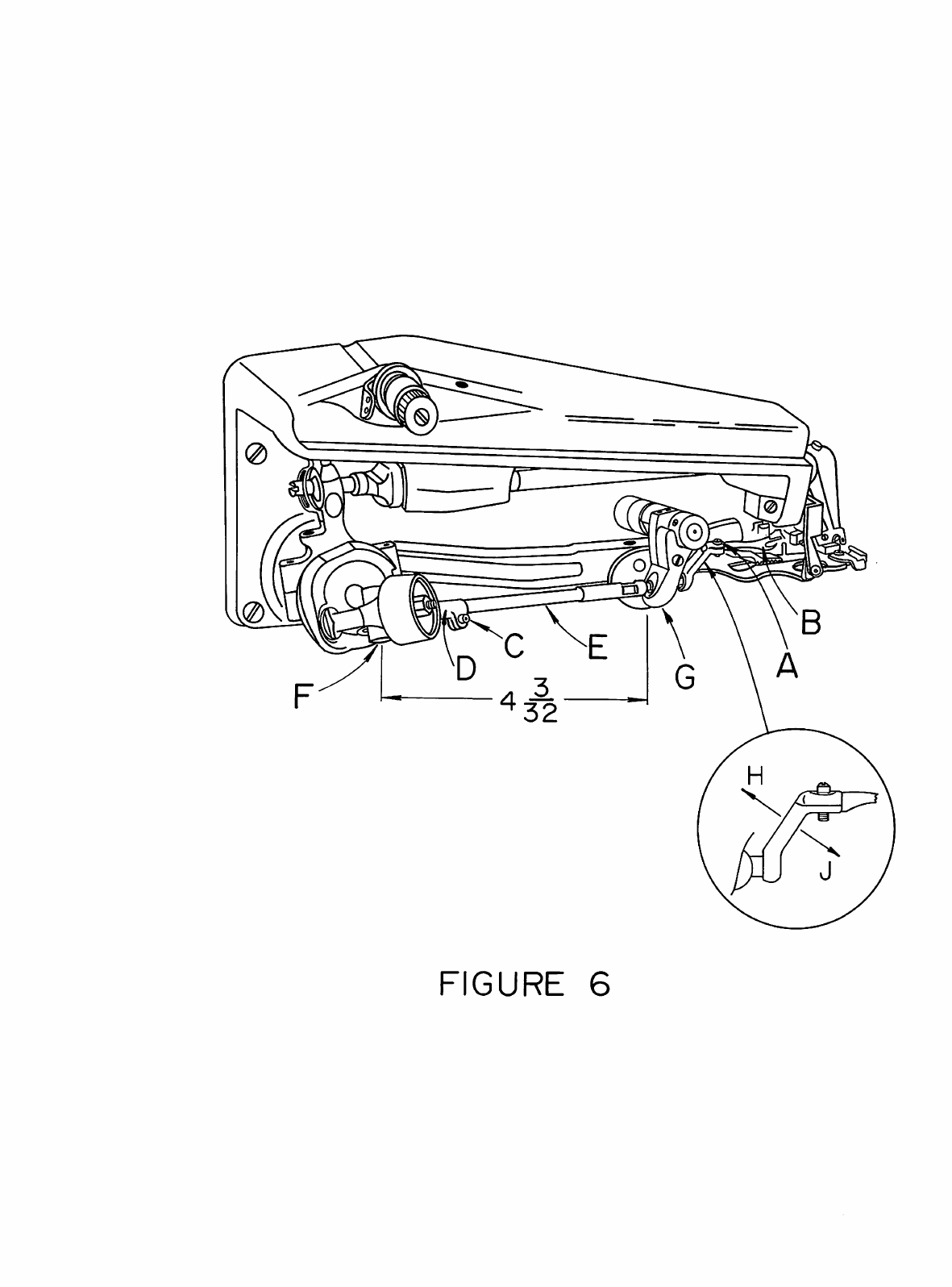

Referring

to

Figure

9, the

loopershould nowclearthe chain-offpin ("D"), feeder("E"), looper slot

("F"), needle, and

pass

overthe needlein the correct position to pick up the

loop.

B.

REPLACING

THE

NEEDLE

GUIDE

1. Afterconsiderable

service,

it maybeexpected that the

wearing

actionof the

needle willcause a sharp edgedgroove to form on the needle guide(item

"G"

in

Figure

9).

This condition can cause thread breakageand uneven penetration.

When

this

happens

the

guide

should

be

replaced.

The

needle

guide

was

specifically

design

ed as a readily replaceablewearplate to prevent

damage

to the presserfoot from

the

action

of

the

needle.

2.

Loosen

the needleguideattachingscrew(item "A" in Figure9) and

remove

the

worn needle guide. Clear

out

any lint or dirt

that

may have accumulated under

the old guideand insert the new guide. Insure that the new guide is seated flush

with the top and sideof the presserfootand then retighten the attaching

screw.

Slowly

turn the handwheel in the direction away from the operator and check

to insure

that

the new guide fits properly

under

the needle and

that

no

inter

ference has been introduced between the guide and the looper.

REPLACING

THE

SHOE

1. The shoe, (item

"E"

in Figure 8), also known as a cloth retainer, normally will

not

required replacement. However, in the event

of

wear due to the particular

fabricsbeingused, or if the shoe or springsuffers any damage,they may be

readily

replaced.

2. The first step is to

remove

the complete front guideassembly by unscrewing the

front guide holder attaching screw (item

"A"

in Figure 8). Next loosen the shoe

pin and the shoe eccentric barrel lock screws, (item

"B"

Figure 8), and slide

out

the shoe pin (item "F"), shoe and retaining spring (item "G")- Beforeremoving

these components it is advisable to note the manner in which the springis

assem

bled so that it may be reinstalled in the same way.

From the library of: Superior Sewing Machine & Supply LLC