U.S. BLINDSTITCH MACHINE CO.

IS A DIVISION OF NEWYORK SEWING MACHINE ATTACHMENT CORP.

2011-15 85th Street, North Bergen, NJ 07047 •Web: www.usblindstitch.com

8

4. Atrial run should now be made along a few inches of work. Do not attempt to pull the work

through the machine as the machine will feed it automatically at the proper rate. The operator

merely needs to guide the work by resting it against the edge guide located on the presser foot.

E. ADJUSTING THE STITCH LINE LOCATION

1. If, on the trial run, it is found that the stitch formation has missed the edge of the hem fold or ribbon,

the edge guide, which is located at the front of the presser foot, should be moved to the left.

2. If it is found that the stitch formation is too far past the edge of the hem fold or ribbon, the edge

guide should be moved to the right.

F. ADJUSTING THE THREAD TENSION

1. Insufficient thread tension will result in a loose, poorly holding stitch. If the trial run indicates this

to be the case, turn the tension nut (item“G”in Figure 3) to the right, thus increasing thread tension.

2. Too much thread tension may result in puckering of the work, thread breakage, and skipped

loops. If this happens, turn the tension nut to the left, loosening the thread tension.

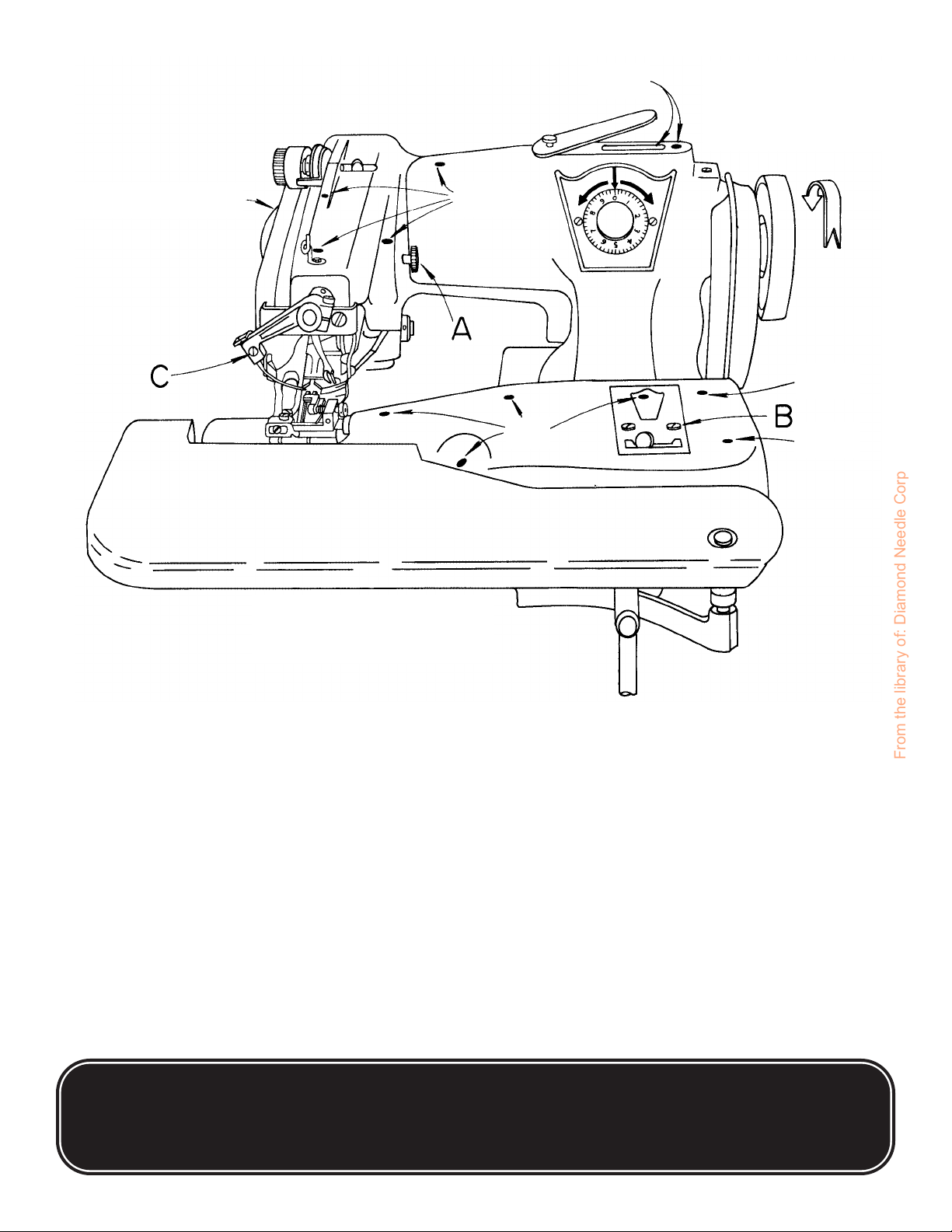

G. ADJUSTING THE DEPTH OF NEEDLE PENETRATION

1. Because of the large variation in the thickness and nature of the fabrics encountered in

production operations, U.S. BLIND STITCH machines incorporate a simple and convenient device

to compensate for these variations. The exact degree of needle penetration desired is obtained by

merely turning the penetration dial conveniently located on the front of the machine as shown in

Figure 4.

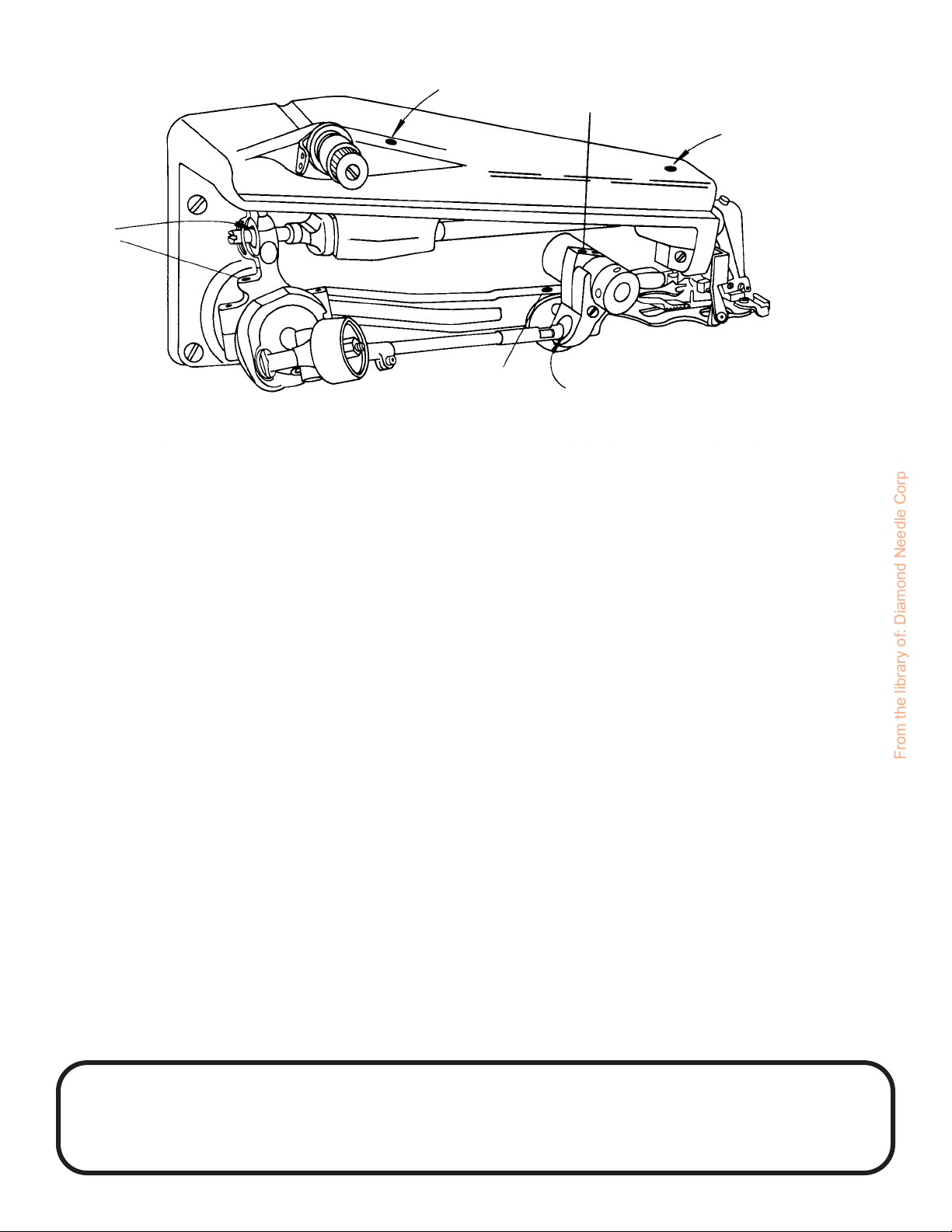

2. The amount of needle penetration of the work which is obtained is governed by the gap between

he needle and the oscillating rib which feeds the work into the needle. This is illustrated by the two

views at the bottom of Figure 4. The view at the left shows a minimum gap which would be used

with thinner fabrics, and the view at the right shows a large gap which would be employed with the

heavier fabrics. Extremely fine adjustments between these two extremes is readily obtainable.

3. Every machine shipped from the factory has been carefully sewn-off and the needle penetration

adjusted exactly for the fabric used during the sew-off operation. When different fabrics are

employed in the actual production operation it will, of course, be necessary to readjust the penetration

as follows:

a. If the needle skips material or a generally deeper and stronger penetration is desired, turn

the knob on the regulating dial (See Figure 4) a few clicks to the left in the direction of the arrow

indicating “More”. This will raise the rib closer to the needle and provide more penetration. This

adjustment should be made gradually, moving only a few clicks at a time, until exactly the correct

amount of penetration is obtained.

b. If too deep a penetration is obtained, turn the knob on the regulating dial (See Figure 4) a

few clicks to the right in the direction of the arrow indicating “Less”. This will lower the rib and provide

less penetration.

c. If the machine has been maintained in the proper adjustment, it should never be necessary

to move too far in either the “More” or “Less” direction in order to obtain the proper penetration. If

a change in excess of four or five numbers on the dial is required without achieving the proper

penetration, the needle should be carefully inspected. A blunted or feathered needle will not provide

the proper penetration. If a good needle is installed and it still does not catch the material, it is likely

that the knob has been turned one or more full revolutions out of adjustment. If for this or any other

reason it becomes necessary to reset the penetration dial to the correct position, the following

procedure should be used.