FLOOD KING

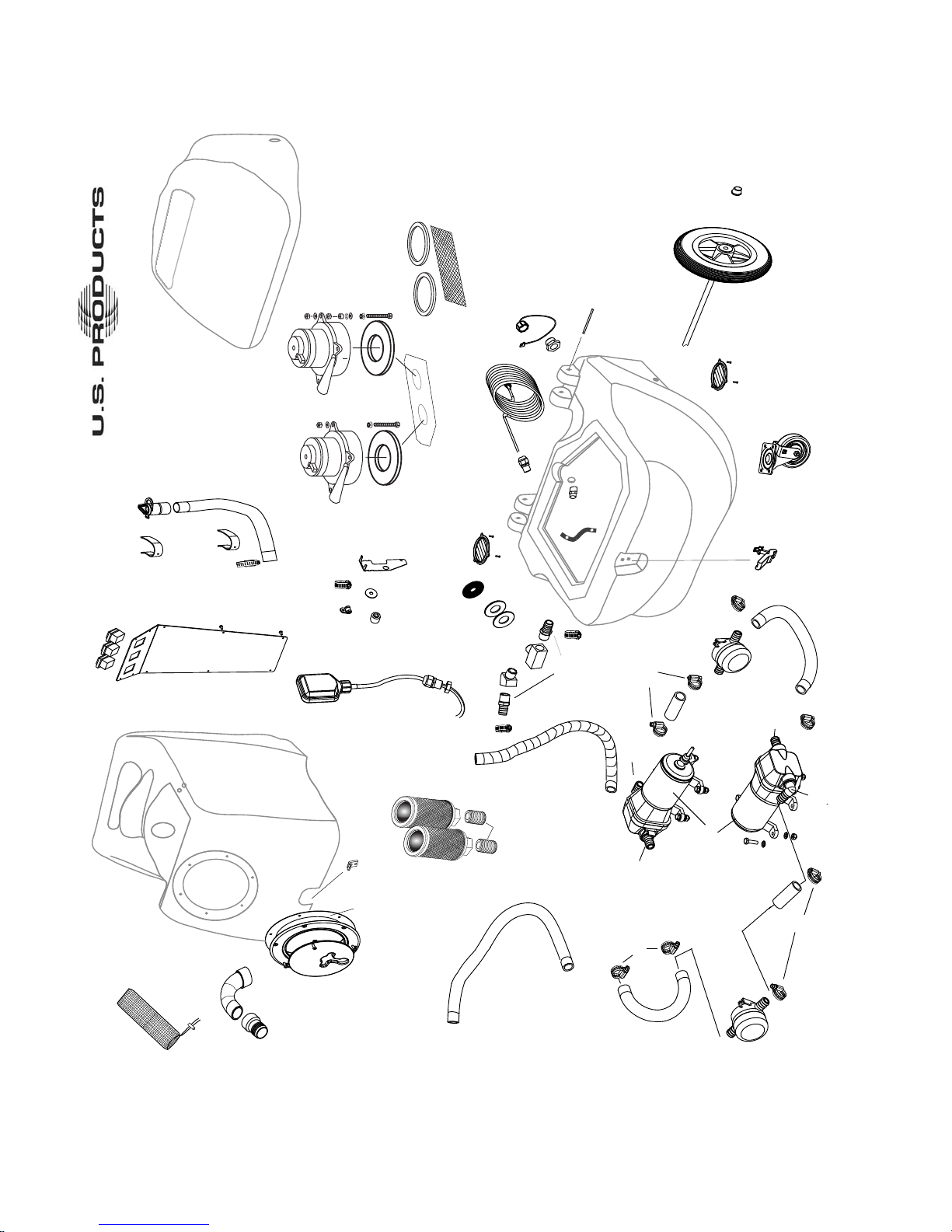

PART LIST

120V

46B 1466 Hose barb/elbow

47 1468 Hose, 3/4” ID X 3”

48 152 “T,” brass

49 372 Elbow, brass, 45 degree

50 928 Louver, 3”, includes screws

51 495A Power cord, 25 ft, 12/3

52 237 Cap, with chain

53 379 Hose fitting

54 152A Washer, flat, S/S

54A 237A Washer, rubber

55 910-24.50 Axle, 24-1/2” long

56 27A Axle cap

57 2084 Wheel, 10”

58 905 Castor. 4”

59 SUBBS-13 Base, drilled, black

60 408E Vacuum motor, 3-stage

61 MA-9 Manifold, vacuum

62 1477 Gasket, under Vac Manifold

63 1056 Screen, wire filter, vac inlet

64 2013A Gasket, under vac motor

65 FP523 Cover, over vacuums

67 937 Coupling, PVC

70 801 Hinge Pin

71 2079 Hose, reinforced, 10”

72 1476 Strap, stop

73 908B Latch & strike

1 2077 Hose Barb, 1-1/2”

2 1463 Eblow, ABS, 45 degrees (3)

3 1464 Bushing, 2” slip

4 SUBVT-25 Tank, recovery

4A 2070B Lid, 6”, vac, with mounting ring

4B 1129 Gasket, for vacuum lid

5 FP521 Strainer bag, vac inlet

9 1434 Switch plate

10 FP578 Switch, SPST

11 1130 Strap, velcro

12 1518 Hose Clamp

14 1060B Hose, drain

16 1060C Plug, drain hose

17 2068 Float, switch

18 230 Retainer, cord

19 196 Clamp, cable

20 1518 Hose Clamp

21 1349 Spacer, float

22 290 Washer, flat, rubber

24 1350 Bracket, float mounting

25 2069 Filter, inlet, 60 mesh, S/S

28 1168 Nipple, PVC, 3/4 X 1-3/8”

32 1468 Hose, 3/4” ID X 22”

33 2079 Hose, 3/4” ID X 14”

34 2079 Hose, 3/4” X 13”

36 378 Hose barb, brass

43 380 Hose clamp

45 2074 Filter, in line, 50 mesh

46 2067 Pump, dump

46A N/A Hose barb. from pump

ItemPart No Description ItemPart No Description

MISCELLANEOUS PARTS

919C Vacuum InletHose, 25ft

717 Hose Cuff, for Vac Hose

956A Drain Hose, 50 ft

971 Bag, Mesh, for hoses