Table of Contents

Contents

Table of Contents..............................................................................................................................................2

Preamble...........................................................................................................................................................4

Required Materials ............................................................................................................................................4

Tools / Supplies..........................................................................................................................................4

Finishing Parts............................................................................................................................................5

Build Steps........................................................................................................................................................7

Cut Out or Dislodge The Pieces.....................................................................................................................7

Chamfer the Control Surfaces........................................................................................................................7

Glue the Horizontal Parts together.................................................................................................................7

Attach the Ailerons and Elevator....................................................................................................................7

Glue in the Carbon Spars...............................................................................................................................8

Wing & Tail Spars.......................................................................................................................................8

Fuse Spar Joiner........................................................................................................................................8

Prepare and mount the Servos ......................................................................................................................8

Mount Aileron Quick Link Connectors.........................................................................................................8

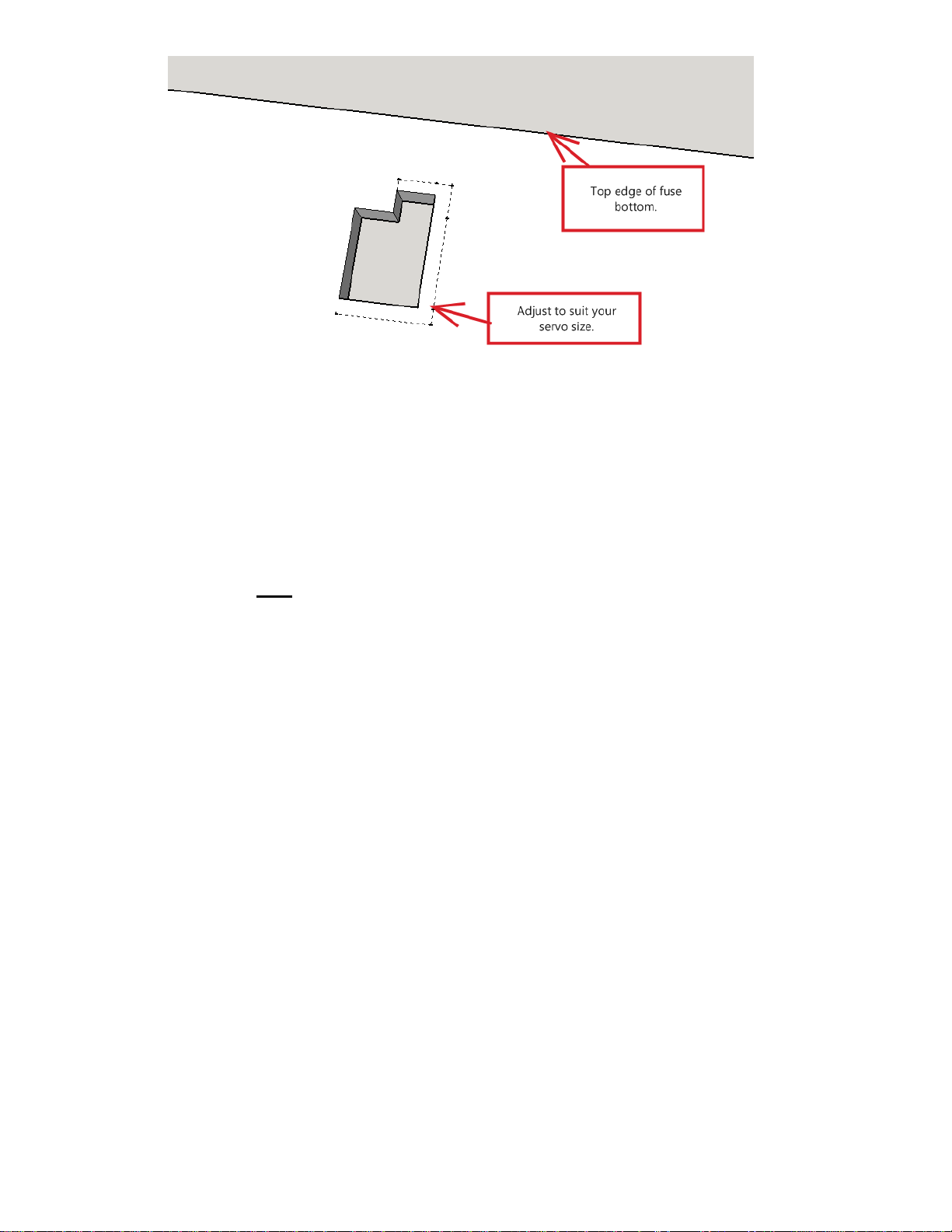

Mount the Servos .......................................................................................................................................9

Glue the bottom fuse onto the Horizontal parts ............................................................................................10

Mount aileron and elevator servo linkages...................................................................................................10

Ailerons....................................................................................................................................................10

Elevator....................................................................................................................................................10

Glue the top fuse onto the Horizontal parts..................................................................................................11

Glue the rudder onto the fuse.......................................................................................................................11

Install the Tail Rotor.....................................................................................................................................11

Remove Tail Rotor Foam..........................................................................................................................11

Install Tail Rotor Motor Mount...................................................................................................................11

Install Fuse Joiners...................................................................................................................................12

Install Tail Rotor Carbon Supports............................................................................................................12

Mount Tail Motor ......................................................................................................................................13

Install tail bracing.........................................................................................................................................13

Mount rudder servo linkages........................................................................................................................14

Mount the nose motor..................................................................................................................................14

Mount electronics.........................................................................................................................................14

Glue on the Side Force Generators..............................................................................................................14

Optionally add landing gear..........................................................................................................................15

Post Build........................................................................................................................................................16

Center all Servo Channels and Controls ......................................................................................................16

Tail Rotor Subtrim / Centering......................................................................................................................16

Program Tail Rotor Mixing ...........................................................................................................................16

Control Throws / DR & Expo........................................................................................................................17