INTRODUCTION

Thank you for purchasin this UFO illuminator

Please read these instructions fully before connectin your unit to the electrical supply, and

keep them for future reference.

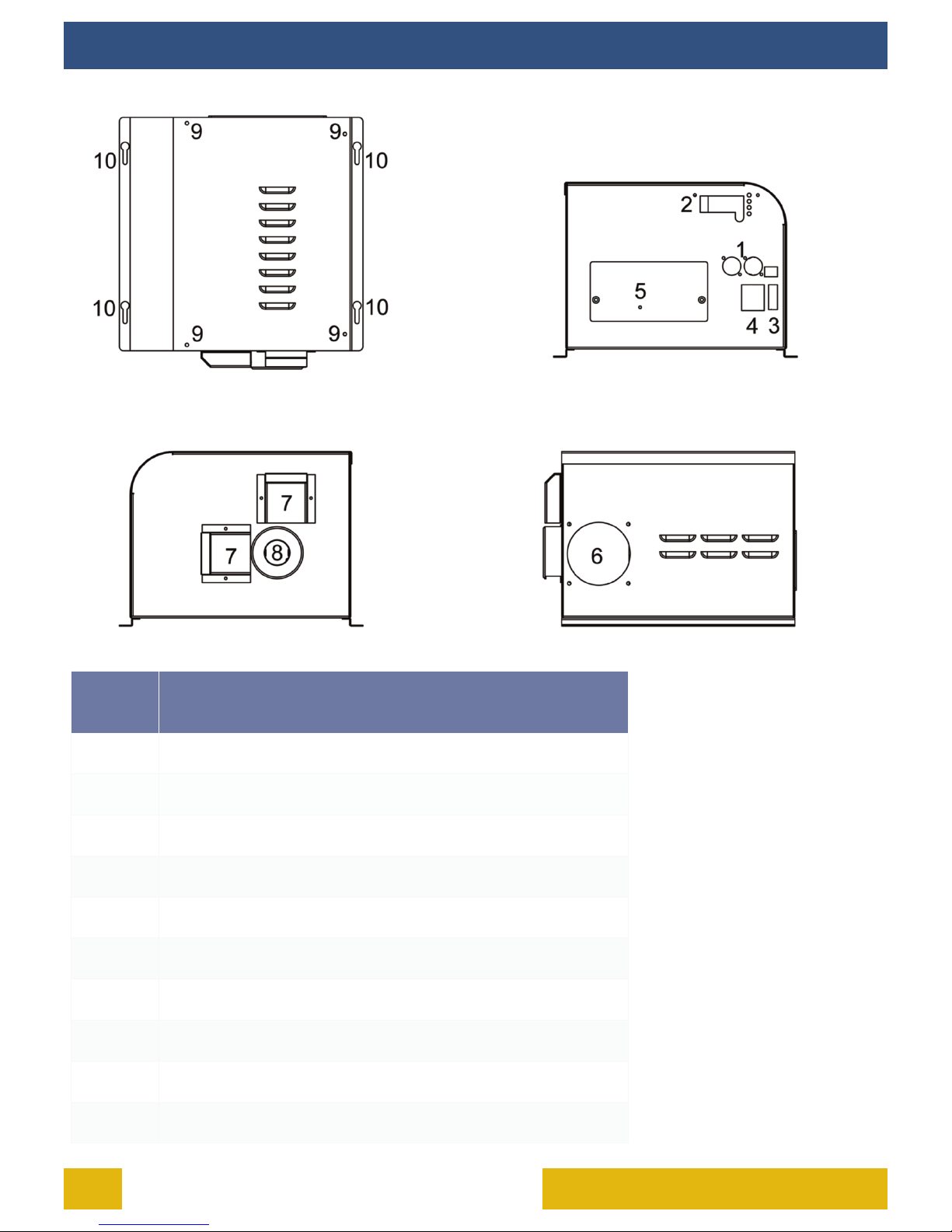

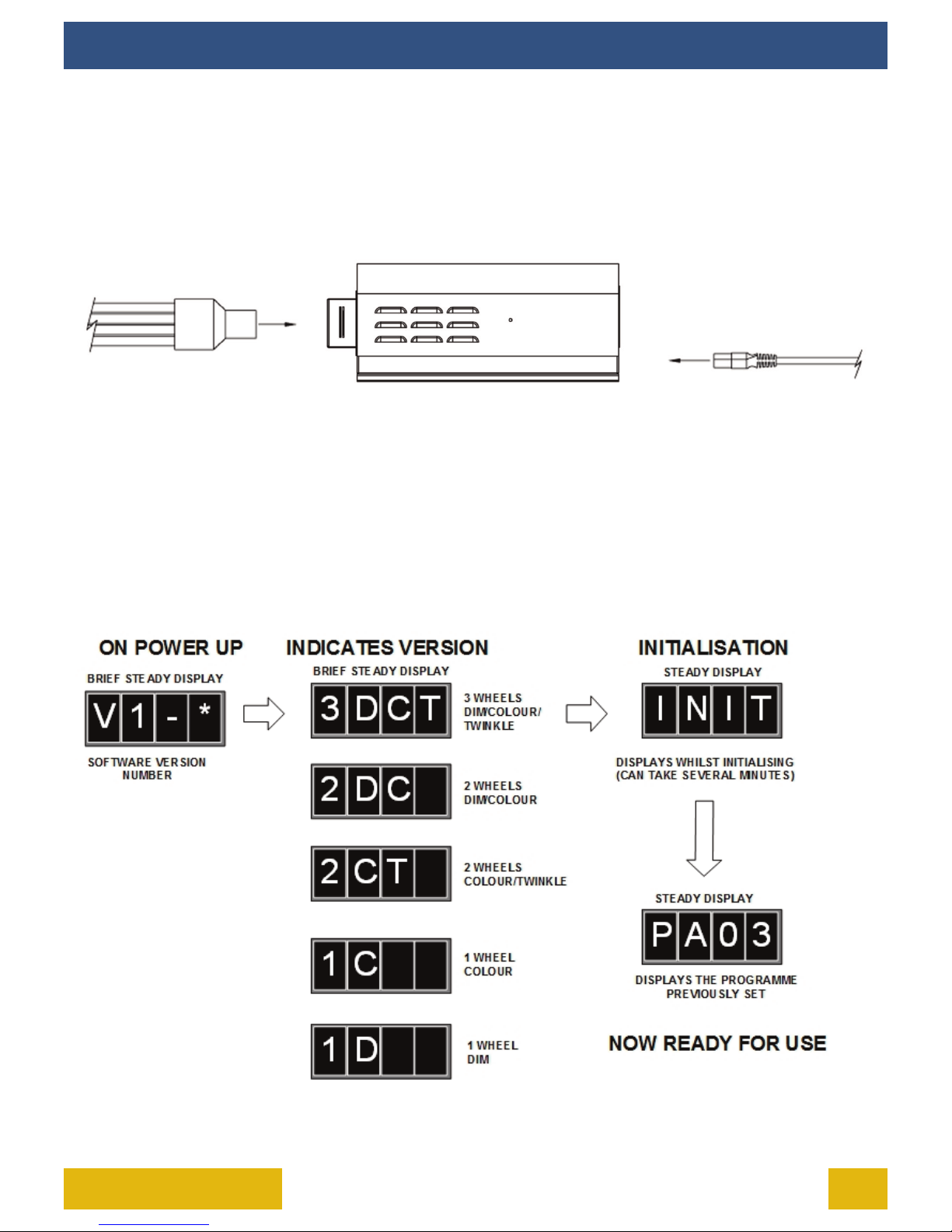

A hi h performance 70W or 150W metal halide illuminator for ultimate bri htness which can be

fitted with up to three decorative wheels as follows:

3DCT – Dimmin , Color and Twinkle

2DC – Dimmin and Color

2CT – Color and Twinkle

1C – Colou only

1D – Dimmin only

We do not recommend that the illuminator be le on for 24 hours a day, 7 days a

week as lamp life will be impaired. A switch off of 30mins per day is recommended.

2150W UNIVERSAL DMX+USER GUIDE

IMPORTANT

WARNING – To reduce the risk of FIRE, ELECTRIC SHOCK OR INJURY TO PERSONS:

1. Unplu and allow to cool before replacin lamp.

2. Always disconnect the unit from the power supply before openin or attemptin

to perform any work on it.

3. Do not touch hot lens, uard, or enclosure.

4. Do not look directly at li hted lamp.

5. Use only with the correct lamp watta e as detailed on the serial label.

6. Do not touch the lamp at any time. Use a so cloth. Oil from skin may dama e lamp.

7. Do not operate product with missin or dama ed uard, lamp containment barrier,

lens or fiber optic harness.

8. Contact UFO for replacement lamp uard, lamp containment barrier, lens or fiber

optic harness

9. Lamp types are matched to the ballast and different watta es/types cannot be

used.

10. Ensure that the power supply is correct for the unit before powerin it up.

11. Always ensure that the unit is properly earthed.

12. Do not expose the unit to rain or moisture.

13. Never attempt to tamper with the wirin or other internal components.

14. Keep the unit away from as, oil and any other flammable or explosive materials.