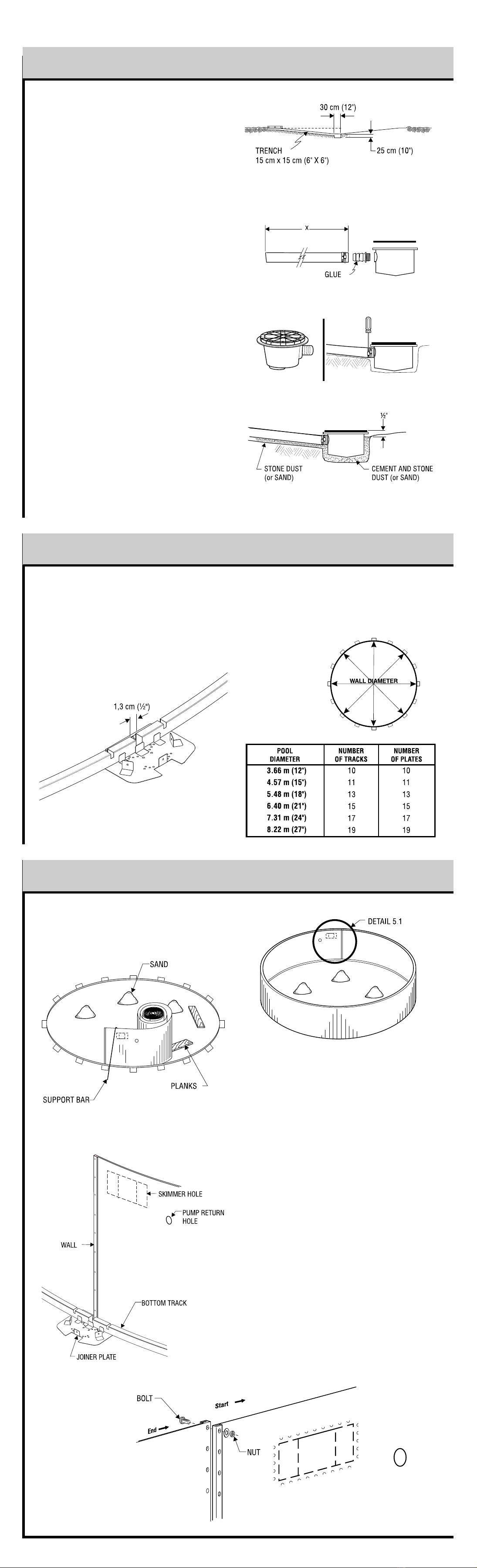

Insert the wall tracks on each side of the joiner plates,

making sure to leave a 1.3 cm (½") space etween the

ends of oth tracks, in the center of the joiner plate (See

Illustration 4.1).

Make a complete circle, using half of the wall tracks and

joiner plates found in the pool kit (See Chart and

Illustration 4.2).

BOTTOM WALL TRACKS ASSEMBLY

4

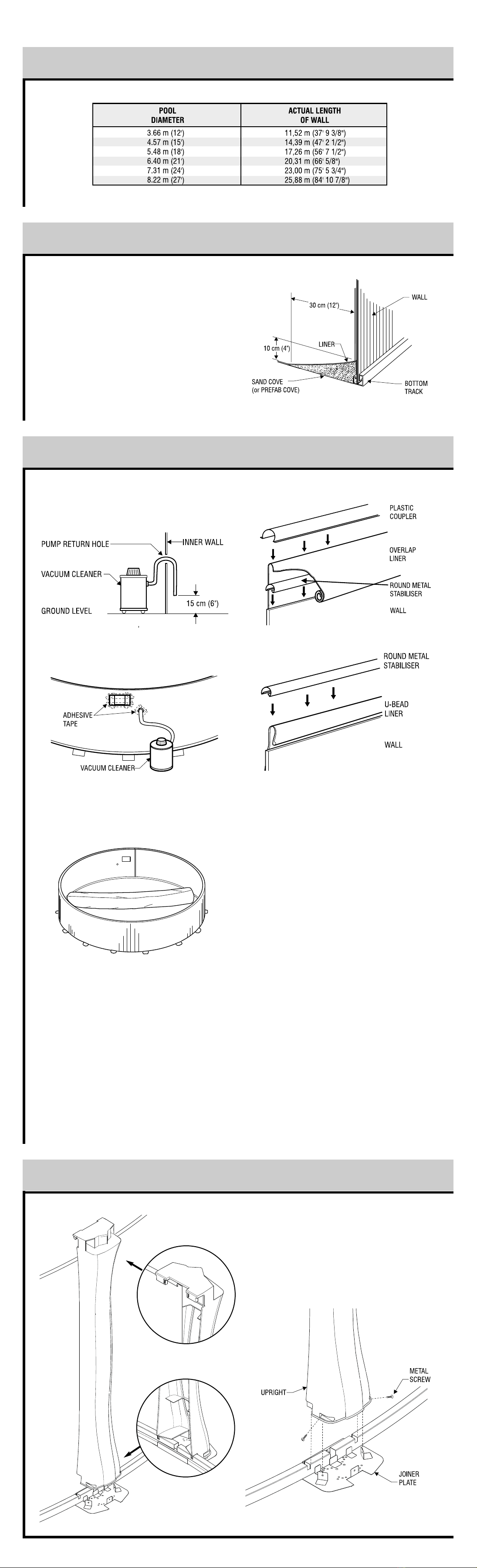

Before uncoiling the wall, make sure the pre-punched

holes for the skimmer and pump return are at the top and

facing the planned location of your filter.

Begin inserting the wall into the ottom wall tracks in the

middle of a joiner plate. At first, the wall should e kept in

place with one or two support ars (or extra persons).

One person should uncoil the wall on a eam or a plank

while a second person inserts it in the ottom wall tracks.

Do not uncoil more than 3 m (10') of wall efore you

install a support ar to reinforce the structure.

Once the wall is completely uncoiled, you may find that it

is too long or that oth ends do not meet y a few cen-

timetres. If such is the case, you must gently push the

wall in or out. If this does not work, roll up the wall again,

realign the grooves and uncoil the wall once more. If the

spread is too wide, measure the wall and check it against

the following chart.

When you prepare to join the ends of the wall, make sure

the end that is reinforced y the fold is inside the circle,

facing the liner and that the other end faces outward (See

Illustration 5.1). When the wall joint is screwed, install the

round sta iliser on top of it.

IMPORTANT: Due to the enormous pressure exerted y

the water on the steel wall, it is a solutely essential that all

bolts are screwed in tightly and that no hole is left open.

All olt heads must e inside with washer and nut outside.

Cover all olt heads with heavy fa ric tape.

WALL INSTALLATION

5

Illustration 4.1 Illustration 4.2

Inside

Outside

Chart

Illustration 5.1 Inside

Outside

Dig a hole 30 cm (12") wide y approximately 25 cm

(10") deep in the center of the circumference.

From the center hole to the projected location of the pool

motor, dig a 15 cm (6") wide trench. Place the removed

soil aside to e used later to cover the hose.

Bottom Drain Assembly

Place teflon around the threaded plug. Screw in drain

holes using large pliers. Glue the connector in the appro-

priate opening.

Take one of the two ru er rings and adjust it to the top of

the drain, aligning the holes carefully. Secure with strips

of adhesive tape to prevent sand from penetrating inside

the holes once the drain has een installed.

Secure one end of the long lack or white hose inside the

drain spout. First apply glue on the drain spout and inside

the drain end, then secure with one or two collars.

Cut the hose so that it ends with the stone dust (or sand).

Measure the pool radius from the center of the drain, then

add 15 cm (6").

Place the assem led ottom drain in the hole so that it is

approximately 1.3cm (1/2") higher than the surface soil.

Bury the hose, levelling the drain as much as possi le.

Compact the soil, using your feet and a tampering tool as

well.

Mix three (3) shovels of stone or sand dust with one half

shovel of pure cement, adding a small quantity of water,

then pour the cement around the drain until it reaches 1.3

cm (1/2") from the top.

BOTTOM DRAIN ASSEMBLY (if applicable)

3