8

www.ultratecfx.com

FDS Option (Fluid Distribution System)

The FDS System is designed for high volume and permanent location installations.

The Bubble Master W/ FDS has a mechanical float installed that opens when fluid is low and closes once the

reservoir has been filled. The Bubble Master W/ FDS is attached by a fluid line to a 5 gallon Bubble Master FDS

Pail to supply the Bubble Master W/ FDS with fluid.

NOTE: The Bubble Master W/ FDS relies on gravity to transfer the fluid from pail to the bubble machine.

Therefore the pail must be mounted higher than the bubble machine.

In applications where the location of the Bubble Master FDS is difficult to get to, a FDS Pump may be added to

the system to fill the Bubble Master W/ FDS pail from a remote location.

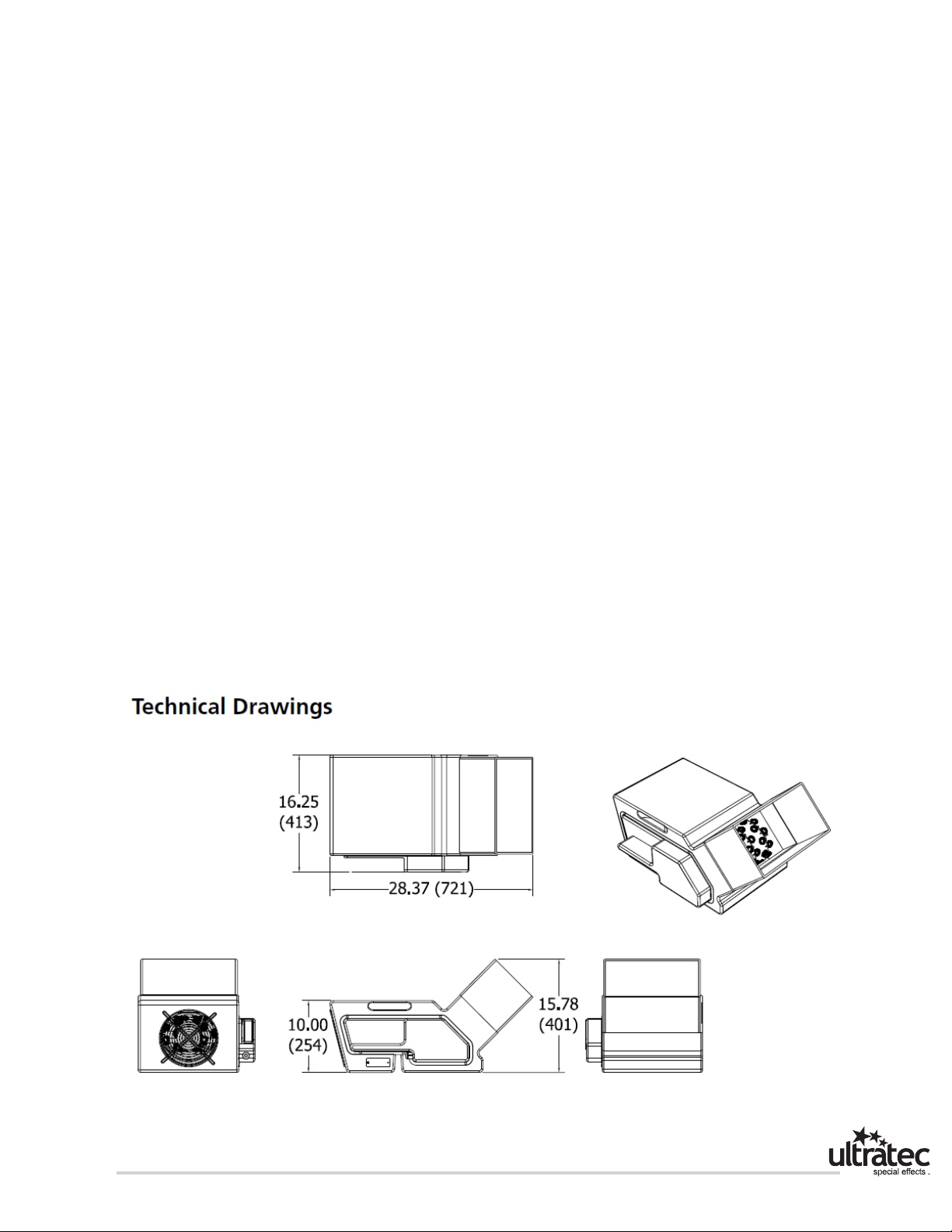

CLB-2010 Bubble Master

FDS Pail

CLF-4145 FDS Pump 110V

CLF-4147 FDS Pump 220V

Troubleshooting

Bubble Wheel not turning:

1. Ensure that unit is plugged into a suitable power source and that power switch is in the ON position.

NOTE: The power switch is breaker type switch. If there is a electrical short; the power switch will trip to the OFF

position.

2. If using speed control dial; see that dial is turned ON.

3. If using hand held remote, see that

Ÿ Duration dial is above 50%

Ÿ The Flow dial is above the 1st hash mark and that

Ÿ The bubble OFF/ON switch is in the ON position.

4. If using DMX see that

Ÿ Correct DMX address is set and

Ÿ That next consecutive DMX address is set above 50%.

Ÿ Confirm that red valid DMX LED is on solid.

5. If using Standalone mode, see that

Ÿ The red valid DMX LED is blinking continuously

Ÿ The ones column is set above 4.

6. Ensure that set screws are secure in bubble wheel motor shaft.

Contact Ultratec Special Effects for further assistance if needed.