UPT Series Easy Melt

Operation Manual

Version 1.2 2

www.ultraflexpower.com

TABLE OF CONTENTS:

1 GETTING STARTE GUI E ................................................................................................................................... 3

1.1 SAFETY INSTRUCTION .............................................................................................................................. 3

1.1.1 IMPORTANT NOTES ............................................................................................................................ 3

1.1.2 SAFETY PRECAUTIONS ........................................................................................................................ 4

1.1.2.1 ELECTRICAL SHOCK HAZARDS ........................................................................................................ 4

1.1.2.2 GROUNDING ................................................................................................................................. 4

1.1.2.3 SAFETY AND PRECAUTION SYMBOLS USED IN THIS MANUAL ......................................................... 5

1.1.2.4 MAGNETIC FIELD ........................................................................................................................... 5

1.2 INSTALLATION AN START UP ................................................................................................................. 5

1.2.1 INSTALLATION PROCE URE ................................................................................................................ 5

1.2.2 UNPACKING AN INSPECTION ............................................................................................................ 6

1.2.3 SELECTING THE EVICE SITE ............................................................................................................... 6

1.2.4 COOLING REQUIREMENTS .................................................................................................................. 6

1.2.5 AC INPUT CONNECTION ..................................................................................................................... 6

1.2.6 START-UP ........................................................................................................................................... 7

1.2.7 USING THE MACHINE ......................................................................................................................... 7

1.3 MAINTENANCE........................................................................................................................................ 8

1.3.1 SCHE ULING ........................................................................................................................................... 8

1.3.2 PERSONNEL ........................................................................................................................................ 8

1.3.3 INSPECTION AN MAINTENANCE PROCE URE ................................................................................... 8

2 PRO UCT SPECIFICATIONS AN FEATURES ......................................................................................................... 9

2.1 PRO UCT SPECIFICATIONS ...................................................................................................................... 9

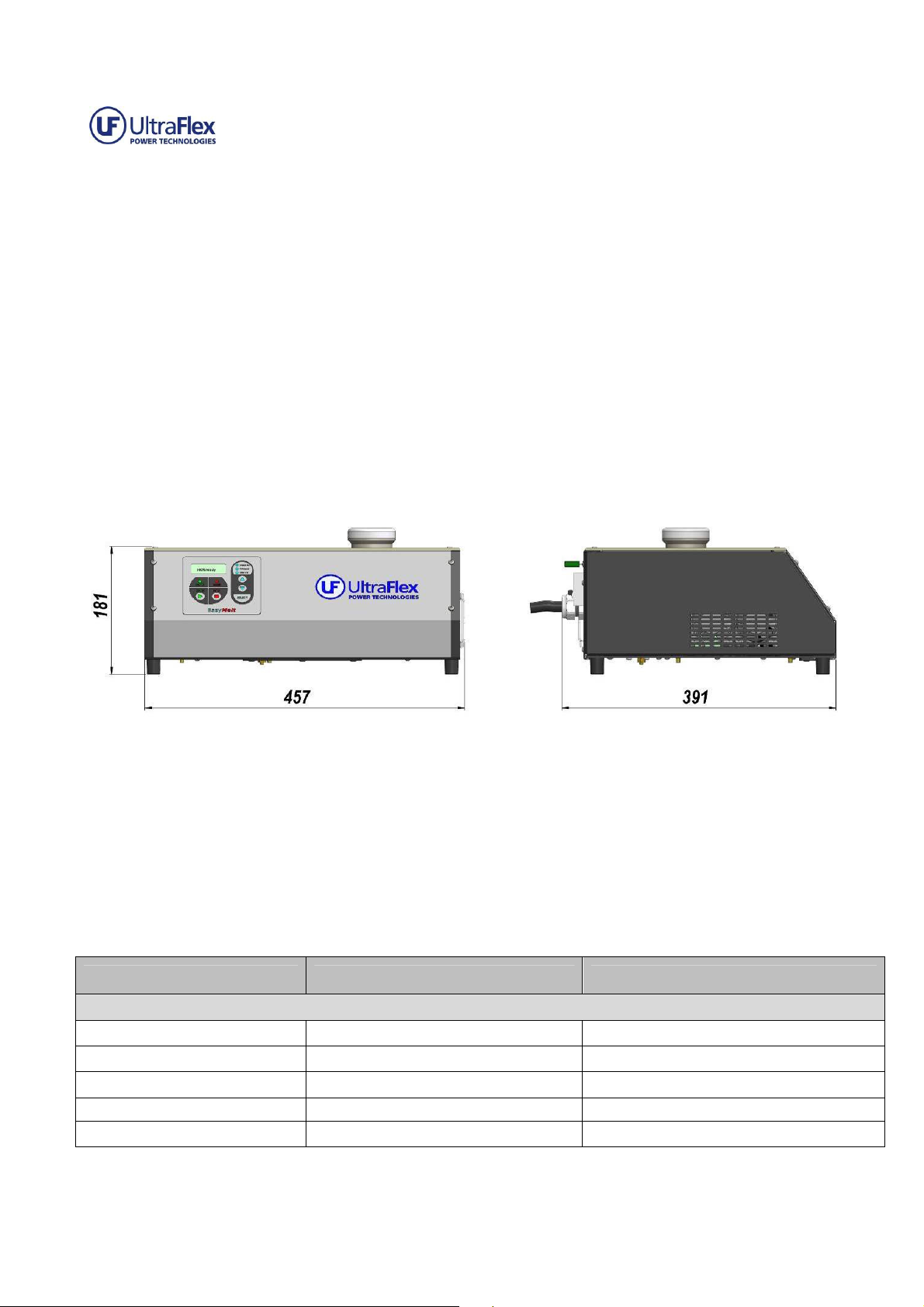

2.1.1 OVERVIEW ......................................................................................................................................... 9

2.1.2 EVICE SPECIFICATIONS TABLE ........................................................................................................... 9

2.1.3 CONNECTION IAGRAM ................................................................................................................... 10

2.2 CONTROLS AN OPERATION ................................................................................................................. 11

2.2.1 CONTROL PANEL OVERVIEW ............................................................................................................ 11

2.2.2 CONTROLS AN IN ICATORS ........................................................................................................... 11

2.2.3 REGULATION MO ES AN SYSTEM STATUSES .................................................................................. 12

2.2.4 MENUS AN NAVIGATION ............................................................................................................... 13

2.2.4.1 Main M nu Navigation ................................................................................................................ 13

2.2.4.2 H at ON M nu Navigation .......................................................................................................... 13

2.2.4.3 SYSTEM MENU Navigation .......................................................................................................... 15

2.2.4.4 EXTENDED MENU Navigation ...................................................................................................... 16

2.2.5 CONTROL MO ES............................................................................................................................. 19

3 TUNING AN TROUBLESHOOTING .................................................................................................................... 19

3.1 LOA TUNING GUI E ............................................................................................................................ 19

3.2 SERVICE AN TROUBLESHOOTING ........................................................................................................ 19

3.3.1 ERROR MESSAGES ............................................................................................................................ 19

3.3.2 GENERAL .......................................................................................................................................... 21

3.3.3 SERVICE CONTACT INFORMATION .................................................................................................... 21

Appendix A: RECOMMEN E SPARE PARTS KIT ................................................................................................... 22

Appendix B: ACCESSORIES ................................................................................................................................... 22