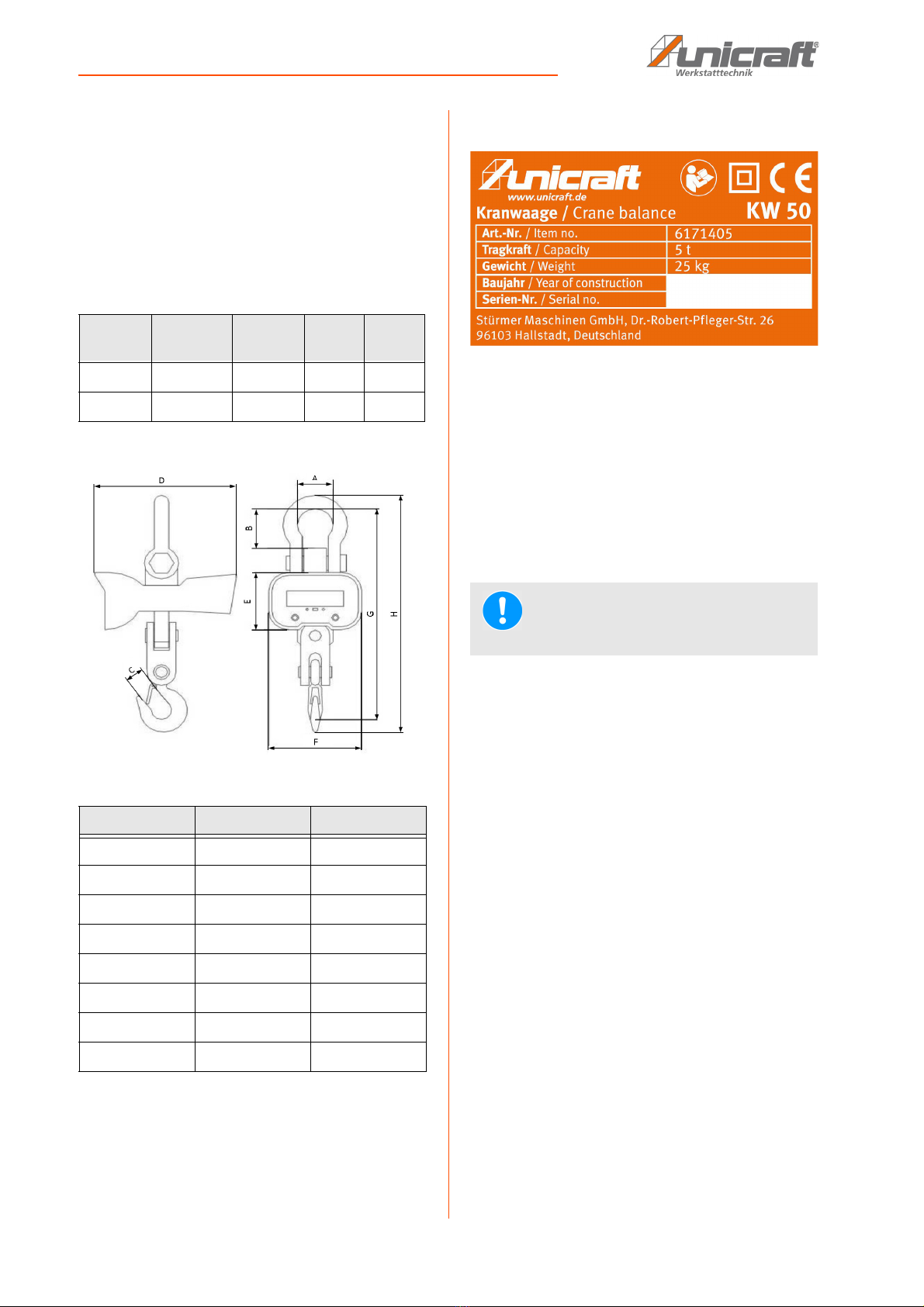

6KW-Series | Version 1.03

Safety

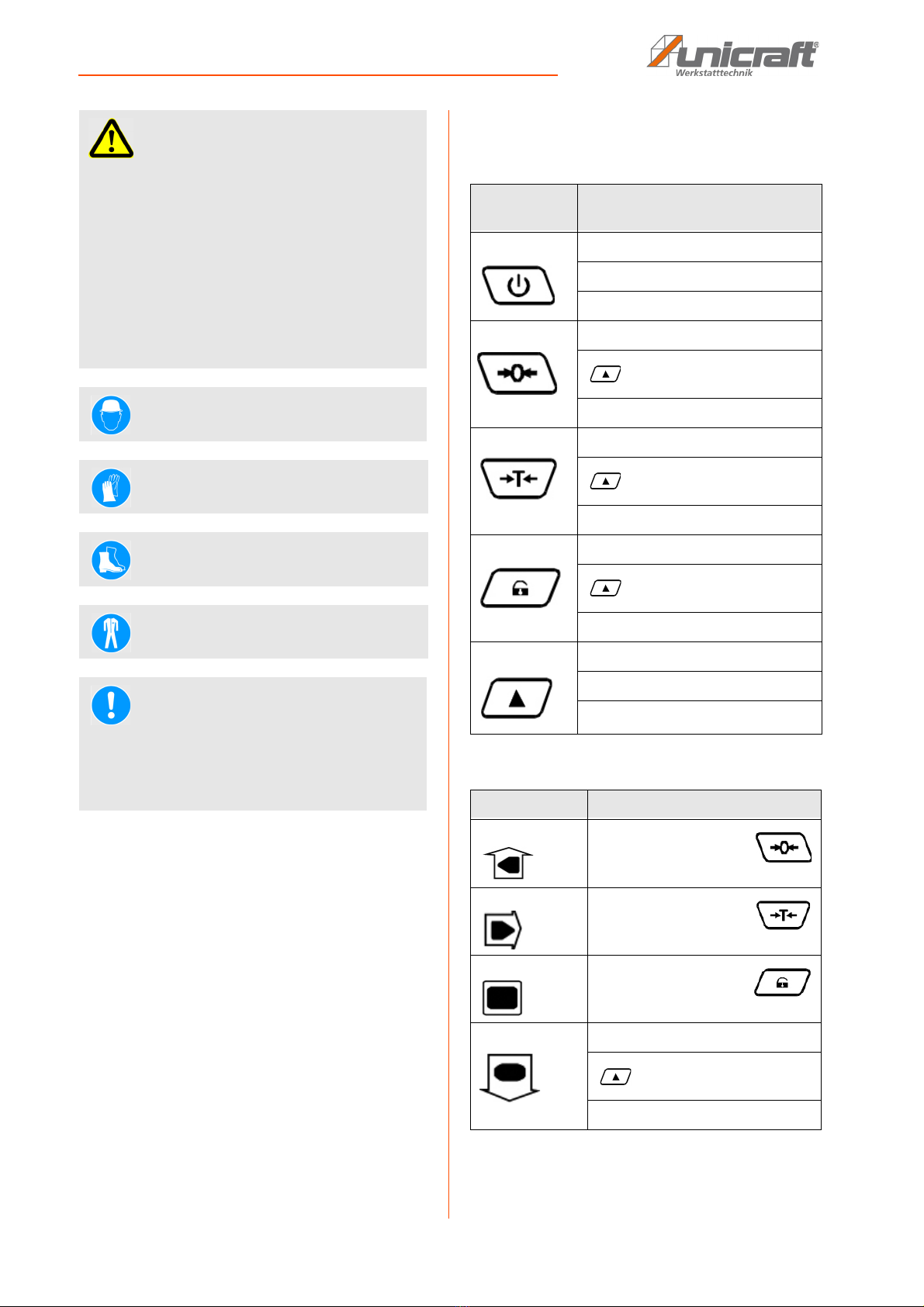

2.5 General safety regulations

Fitting, retrofitting, maintenance and inspection work

may be carried out on non-operational equipment only

and by trained personnel only.

For reasons of safety, unauthorised modifications and

changes to the crane scales are not permitted.

Operating personnel must always ensure that the maxi-

mum load is never exceeded.

Personnel must not stand underneath a suspended load

as this could come loose and fall.

Personnel must not ride on or be lifted by the equip-

ment. Access to lifting equipment is not permitted.

2.6 Safety information for operating personnel

No operational mode which could compromise the safety

of the crane scales may be undertaken

It is the responsibility of the operator to ensure that no

unauthorised personnel work on the crane scales (e.g.

also by working on equipment in a manner contrary to

authorised use).

It is the responsibility of the operator to check the crane

scales at least once before use (once a day) for exter-

nally apparent damage or defects and to report any

changes (including to the way the machine is operating)

which are likely to compromise safety.

It is the responsibility of the operator to ensure that the

crane scales is operated only in perfect order and con-di-

tion.

It is the responsibility of the operator to insist that oper-

ating personnel must wear protective clothing wherever

necessary.

Under no circumstances must safety devices be re-mo-

ved or put of operation (potential risk of serious crushing,

danger to life).

If it is necessary to remove any safety devices for fitting,

repair or maintenance work, they must be re-installed im-

mediately after maintenance or repair is complete.

2.7 Tests

Lifting equipment is a testable suspension. It is therefore

the Guidelines for Hoists issued by the German Employ-

ers' Liability Insurance Association, the Central Agency

for Accident Prevention, the Test Guidelines and the test

regulations according to DIN 685 Part 5 Nov. 1981, UVV,

DGUV Regulation 54 and UVV, DGUV Regulation 54

and UVV, DGUV Regulation 52 and DIN EN 818-7 of

September 2002.

The entry in the crane test book must be made via re-

pairs and tests carried out.

2.8 Basic security instructions

For good performance and accurate measurement, the

points below should always be followed:

1. DO NOT overload the scale. Overloading will damage

the load cell and void the warranty.

2. Do not attach a permanent load. This can damage the

measuring mechanism as well as safety-relevant

parts.

3. It is essential to prevent overloading of the balance

above the specified maximum load (Max), less any

Tara load that may already be present. This could da-

mage the scale (risk of breakage!).

4. Check chain and hook before each use. Check the

clamp, pins and screws regularly.

5. Check the battery constantly. If the scale is no longer

supplied with power, charge the battery with the

appropriate charger or replace it with a full battery.

6. Turn the load, if necessary, instead of the balance.

7. NEVER use the scale during thunderstorms (lightning,

rain, etc.).

8. Store the device in a dry and well-ventilated area. The

crane scale must NOT be stored outdoors.

9. NEVER attempt to repair the balance yourself.

10. Only load the balance in the vertical direction of pull.

11. Always avoid vibrations and horizontal forces.

12. Avoid sudden, sudden acceleration or deceleration

of the load (risk of breakage!).

HINWEIS!

All local regulations (the latest valid version) which

apply in the country where the device is used must be

complied with

In Germany, currently

DGUV Regulation 1 - The principles of prevention

DGUV Regulation 3 - Electrical systems and means

of production

DGUV Regulation 52 - Cranes

DGUV Regulation 54 - Jacks, Lifting and Pulling

Equipment

DGUV Regel 100-500 Chapter 2.8 (BGR 500) -

Operating Lifting equipment

DGUV Principle 309-001- Testing of Cranes

EG machine directives 2006/42/EG