FORCE 50

REV. 2.2 2021-02-04

3-2

UNIFIRE FORCE 50 Robotic Nozzle

Installation and setup manual

PLANNING

PLANNING - BEFORE INSTALLATION

About This Manual

This manual is a comprehensive guide that contains the

information necessary to design, install, operate, and

maintain the FORCE 50 Robotic Nozzle system.

Users of this manual are assumed to be competent fire

engineers with a basic knowledge of such systems. Users

who are not familiar with the equipment should first read the

complete manual.

Only certified personal who have undergone UNIFIRE AB

training are allowed to install this equipment.

Contacts

Should any part of this manual not be understood, or there

are queries concerning the system, contact UNIFIRE AB

Technical Support using the following details:

UNIFIRE AB,

Bultgatan 40B

442 40 KUNGÄLV

SWEDEN

www.unifire.com

APPROVALS AND STANDARDS

See Section 2 System Components for approval and listing

information for the various components.

SAFETY warnings

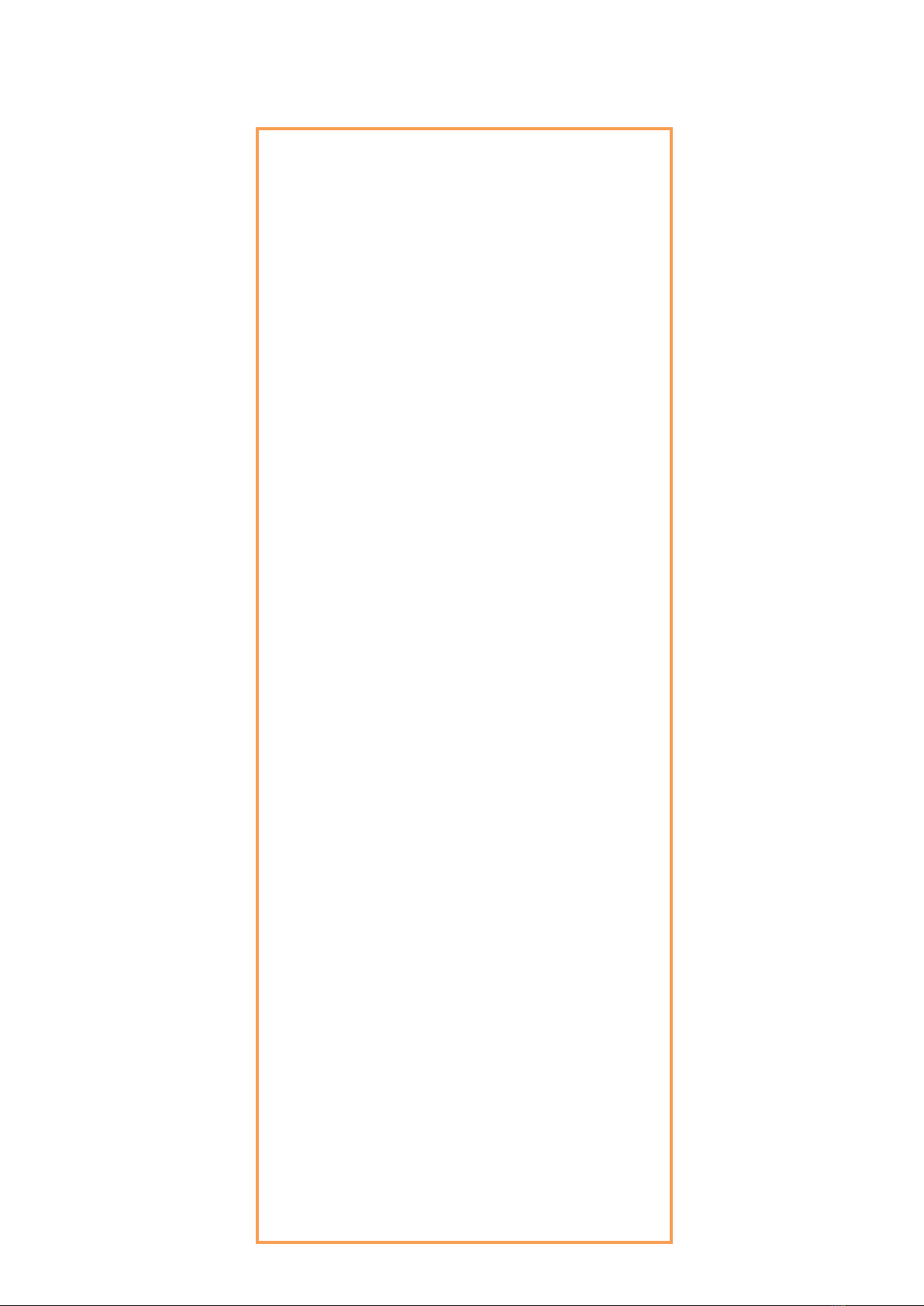

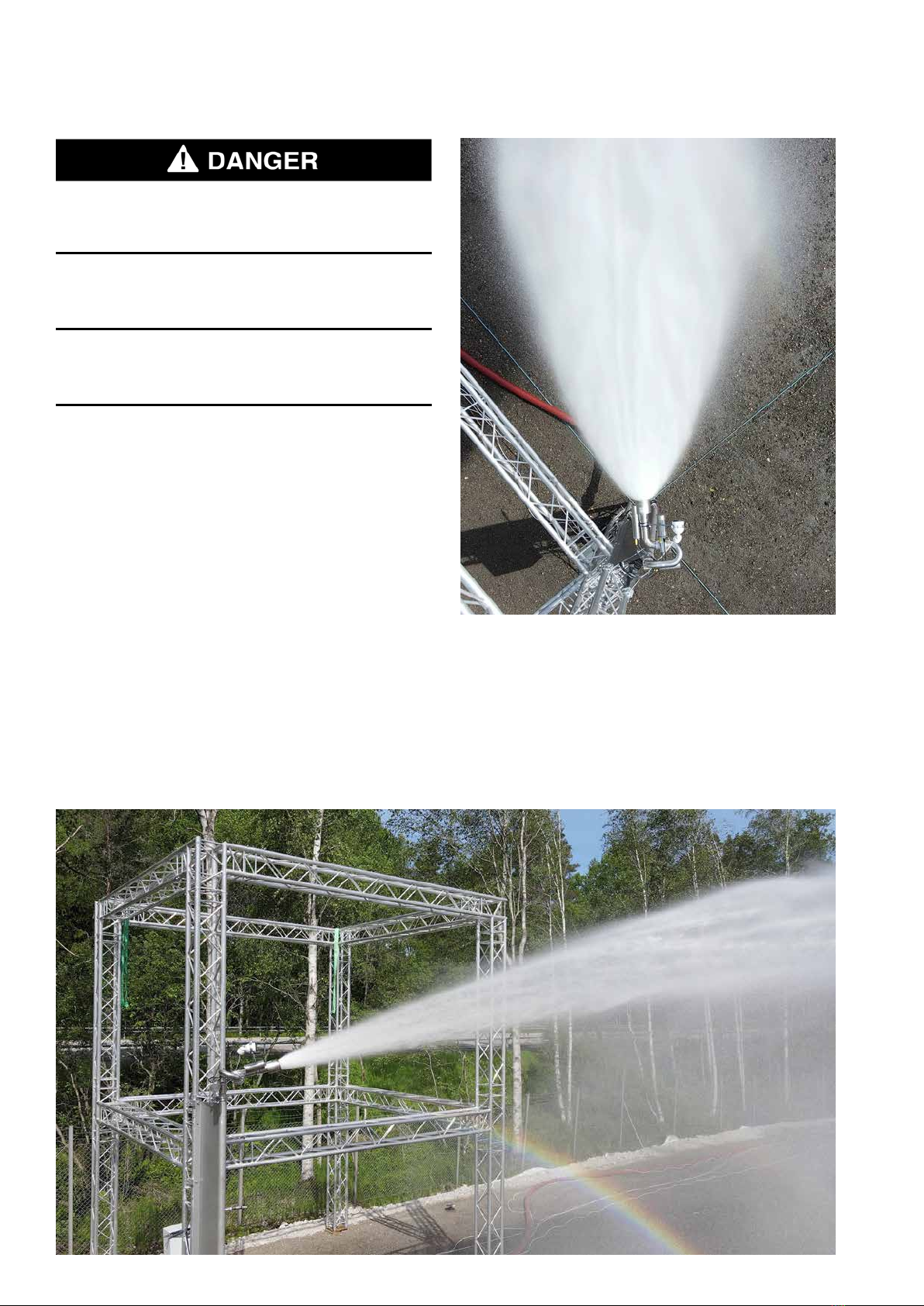

A properly designed and installed FORCE 50 Robotic

Nozzle should not present any significant health or safety

problems. Take basic precautions to avoid accidents. The

various aspects of the system’s operation must be under-

stood. Observe best practices.

Do not operate this device without a full understanding and

comprehension of this manual. Personnel responsible for

the FORCE 50 system must be fully trained on the system

components.

The installer should pay specific attention to the danger,

caution, warning, and notice statements in this manual.

Failure to observe safety warnings could cause serious

injury, and potentially create liability.

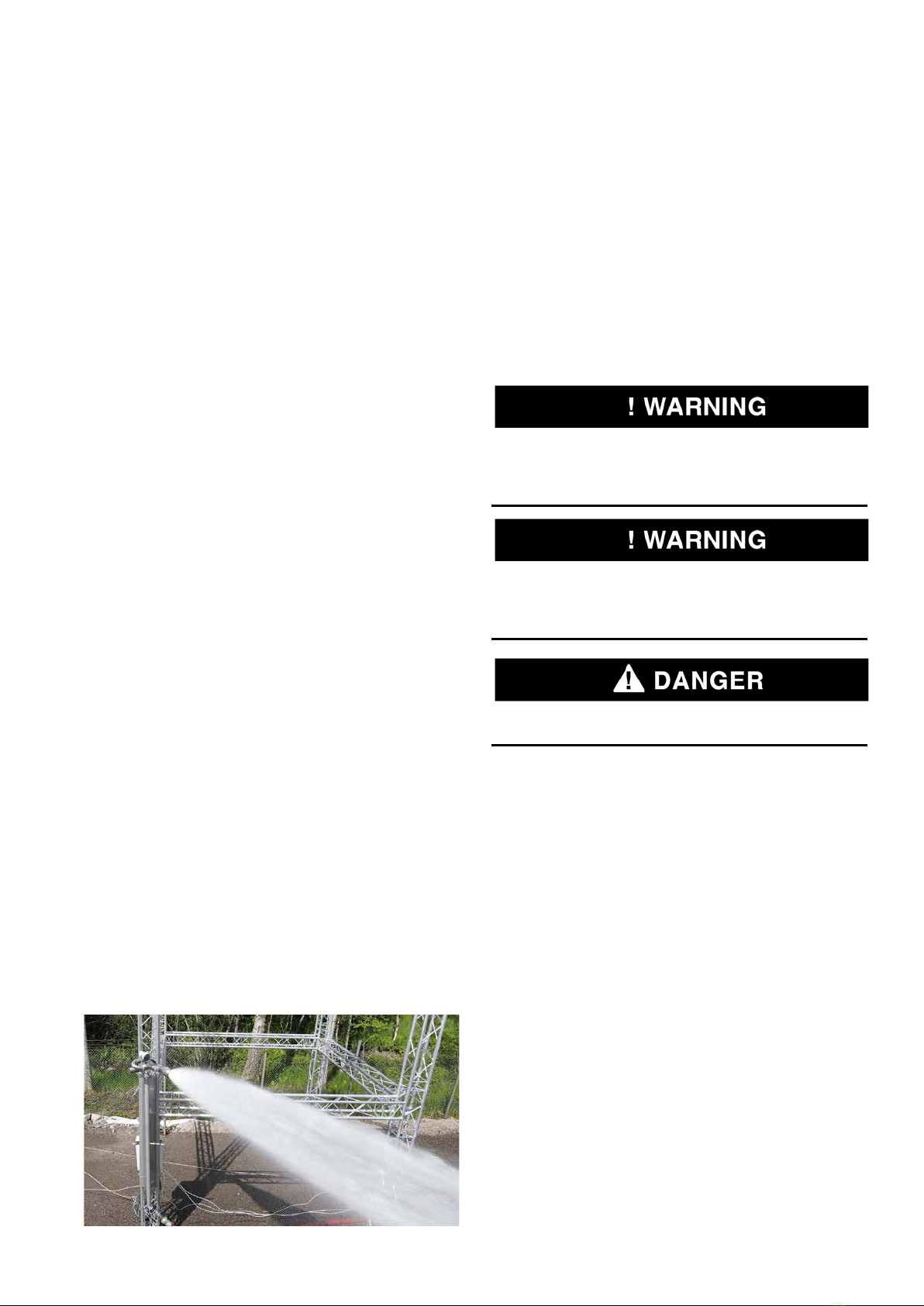

Do not direct the flow stream towards people as it could

result in serious personal injury or death.

• Operate and maintain the FORCE 50 Robotic Nozzle

system in compliance with this document and with appli-

cable standards, in addition to the standards of any other

authorities having jurisdiction (AHJ). Failure to do so

impairs the proper operation and integrity of this device.

• The owner must maintain the fire protection unit or system

and devices in proper operating conditions.

• Do not, under any circumstance, operate this system

outside the water flow or pressure range indicated in this

manual.

• The owner must ensure that an uninterrupted supply of

water is maintained to the Robotic Nozzle.

Authorized Personnel

The FORCE 50 system shall be installed by

authorized personnel certified by UNIFIRE AB. Use compo-

nents and accessories authorized only by UNIFIRE AB.

Structural Alterations

This installation manual details the suggested installation

method. Any structural alteration necessary for installation

must comply with local building code requirements.