9

REFRIGERANT CONNECTIONS

The condenser has male rotalock connections.

The condenser is factory charged with dry nitrogen to

prevent the ingress of humidity and the connections are

sealed with plugs.

BEFORE REMOVING THE PLUGS FROM THE

CONNECTIONS, DISCHARGE THE NITROGEN BY

MEANS OF THE NEEDLE VALVE ON THE INLET

MANIFOLD.

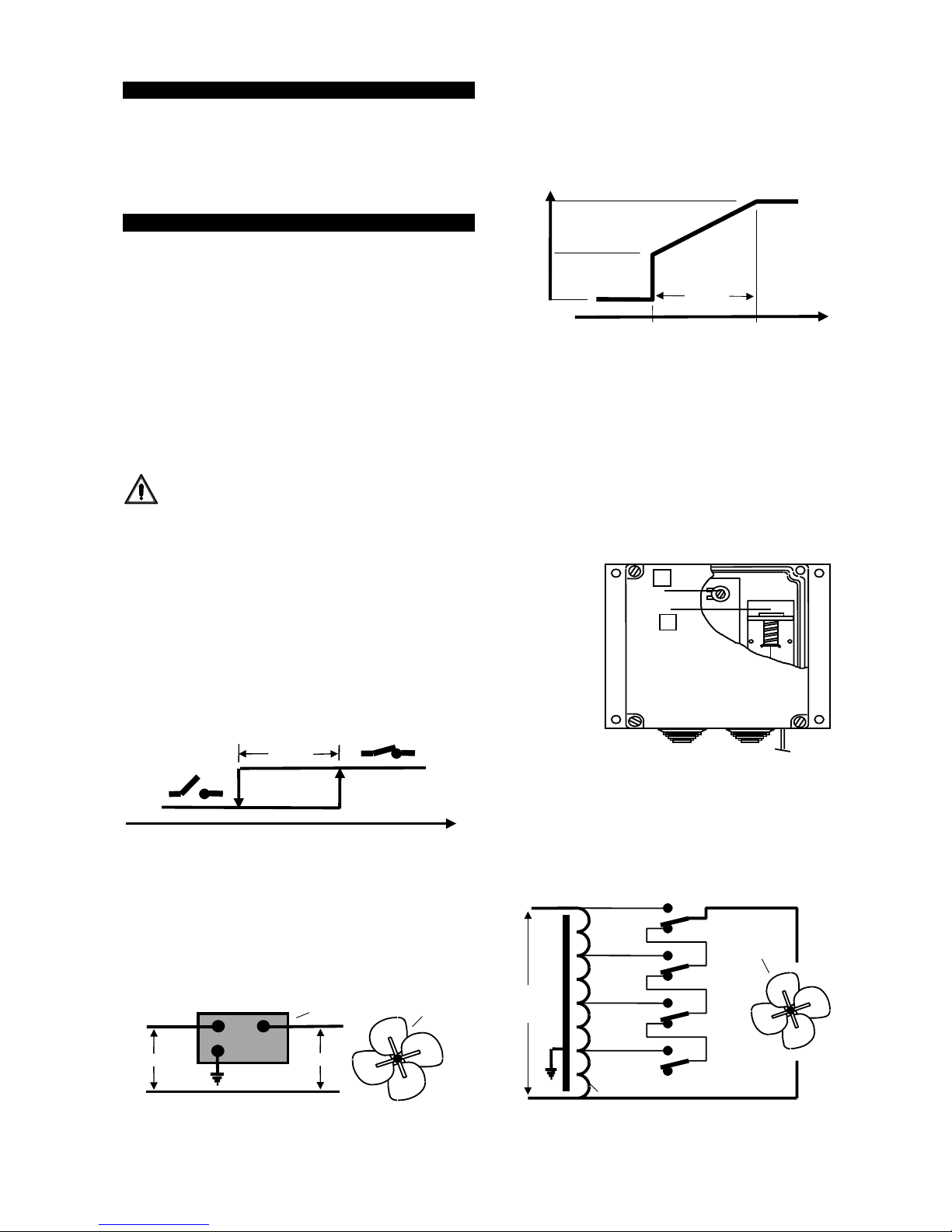

Connection to the condenser can be achieved with one of the

following rotalock connectors:

3a) straight connectors: see fig. 3a;

3b) right angle connectors (supplied on request): see fig 3b;

3c) service valves (supplied on request): see fig. 3c:

to which the interconnecting pipework is connected.

A: ROTALOCK

CONNECTIONS

B: SEAL

Fig. 3

Take care that the connections are correctly made and in

particular do not invert the inlet and outlet connections (see fig.

4)

Fig. 4

Run the refrigeration lines taking care to ensure the following

(see also fig. 5);

•use straight line routes wherever possible;

A: discharge line

B: liquid line

C: trap

Fig. 5

•incline the discharge line with a gradient of 1/100 in the

direction of flow to facilitate oil entrainment;

•make a ‘U’ trap in the discharge line at the bottom of any

vertical risers;

•thermally insulate the refrigerant liquid line wherever it may

be exposed to sun;

•avoid any contact between the discharge line and the liquid

line.

Carry out the evacuation and charging of the complete

refrigerant circuit.

ELECTRICAL CONNECTIONS

CABLE SIZES - PROTECTION

(see wiring diagram SECA ......... attached)

The condenser can be operated automatically and

autonomously (as a function of the refrigerant pressure ) and

therefore its power supply does not necessarily have to come

from the indoor unit to which it is connected. It can come from

the nearest convenient distribution board.

Check that the voltage and frequency of the power supply

correspond to the data shown on the nameplate of the

condenser.

Connect the power supply cable to the isolator introducing the

cable into the switch box through an IP 55 rated cable gland

and screw the terminals down tightly.

The following table lists the principal electrical data needed for

the connection.

VOLTAGE No. kW FLA mm² FUS

CAL0231 230V/1ph/50 1 0,14 0,7 1,5 10 A

CAL0251 230V/1ph/50 1 0,14 0,7 1,5 10 A

CAL0331 230V/1ph/50 1 0,14 0,7 1,5 10 A

CAL0361 230V/1ph/50 2 0,28 1,4 1,5 10 A

CAL0511 230V/1ph/50 2 0,28 1,4 1,5 10 A

CAL0661 230V/1ph/50 2 0,28 1,4 1,5 10 A

CAL0801 230V/1ph/50 3 0,42 2,1 1,5 10 A

CAL1011 230V/1ph/50 3 0,42 2,1 1,5 10 A

CAL1301 230V/1ph/50 4 0,56 2,8 1,5 10 A

CAL1511 230V/1ph/50 5 0,70 3,5 1,5 10 A

CAL1801 230V/1ph/50 6 0,84 4,2 1,5 10 A

No. : Number of fans

kW kW : Nominal power

FLA A : Max. absorbed current

mm² mm² : Recommended cable size

FUS AT : Short circuit protection recommended

(for cable runs up to 30 m)

N.B. : The condenser is fitted with overload protection (bi-

metallic switch in each motor) but not against short circuit; so

feed the condenser via a suitable protection device (fuse or

circuit breaker of appropriate rating ).

OK

B

A

3a 3b

B

A

3c

B

A

B

1/100

A

max 5 m

max 30 m

1/100

A

Bmax 15 m

B

A

C

1/100