6. Do not use the power cable if it is damaged in any way. Doing so may result in electrical shock or fire.

7. Do not insert or drop metal or objects which are easily combustible through the openings such as the

ventilation hole of your cutter. Doing so may result in electrical shock or fire.

8. Do not operate the cutter if it has been contaminated by foreign substances or liquid spills as doing so may

result in electrical shock or fire. Immediately turn off the power switch, disconnect the power plug from the

electric socket, and contact your authorized dealer.

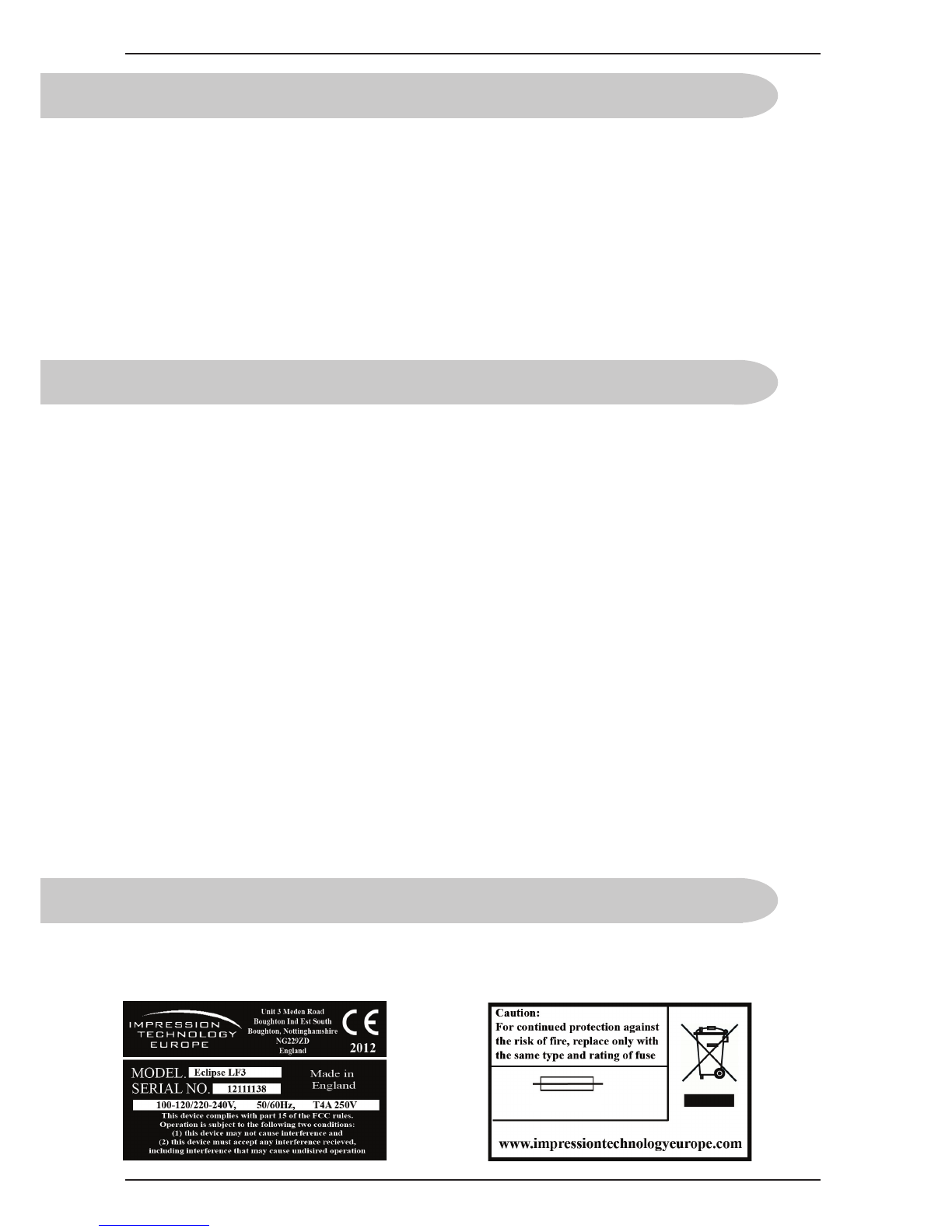

9. Make sure to use only the specified power supply (AC 100 V / 120 V - AC 220 V / 240 V). If the power

supply other than the specified voltage is used, it could cause an electric shock and fire.

10. Take power for the cutter directly from the power socket (AC 100 V / 120 V - AC 220 V / 240 V). Do

not use complex multiple plugs on the same socket. This could generate heat and might cause fire.

11. Make sure that the following is performed before parts replacement.

• Turn off the power to the printer.

• Remove the power cable from the power outlet. Not doing so may cause electric shock or damage

to the electric circuit.

• Unplug the cables connected to the printer. Failure to do so could result in damage to the printer.

12. Do not wear any loose clothing and tie back any long hair

whilst operating this machine, failure to adhere to this warning

could result in serious injury.

13. Do not remove the rear cover with the power on, high voltage

power units are located behind the cover, only a trained LF350

Technician should remove the panel.