UNION TOOL 5 Series User manual

Page 2

Union Series #5 / #15 / #45 Roller Coaters

STANDARD OPERATING MANUAL

TABLE OF CONTENTS

A

INTRODUCTION

Page 3-4

B

SAFETY

Page 5-7

C

INSTALLATION

Location

Page 8-9

D

WIRING

Page 9

E

OPERATING INSTRUCTIONS

Roll Adjustments/Roll Change Out

Page 10-14

F

ROLL MOUNTINGS

Feeding/Before Starting

Page 14-15

G

PICKOFF FINGERS

Page 16

H

GUARDS

Page 16

I

DOCTOR ROLL SAFETY

FEATURES

Page 16

J

LUBRICATION

Page 17

K

CLEANING

Page 17-18

L

TROUBLE SHOOTING

Page 19-20

M

MAINTENANCE CHECKLIST

Page 21

N

STANDARD FEATURES

Page 22-28

Page 3

INTRODUCTION

This manual was prepared for “standard” Union Roller Coaters. Union Tool

provides standard machines, as well as, special machines for your particular

application. This manual provides “in-general” information on our standard

equipment. Some of the information may not pertain to your particular

machine, but will provide you with a general overall lubrication and

maintenance guide, as well as, troubleshooting.

Should your company or operator have any questions regarding this manual,

please do not hesitate to contact the Union Tool Corporation, Technical Sales

Department at 574-267-3211. Our hours are 8:00 A.M. through 5:00 P.M.

Eastern Standard Time –Monday through Friday.

Union Roller Coaters are designed to apply a smooth, even, controllable

coating of liquid materials, such as: glue, resinous adhesives, drawing

lubricants, paint, wax, oil, sizing, silicone solutions, etc. to many reasonably flat

surfaced substrates. Roller coating eliminates the human error, wasteful

application, and the poor general coverage of spray or hand coating. “Dry

Spots”and "Squeeze Out" is prevented and quality control is easily maintained.

All of our series #5 / #15 / #45 roller coater frames are manufactured with

welded tubular steel and plate steel construction.

Page 4

INTRODUCTION

(Continued)

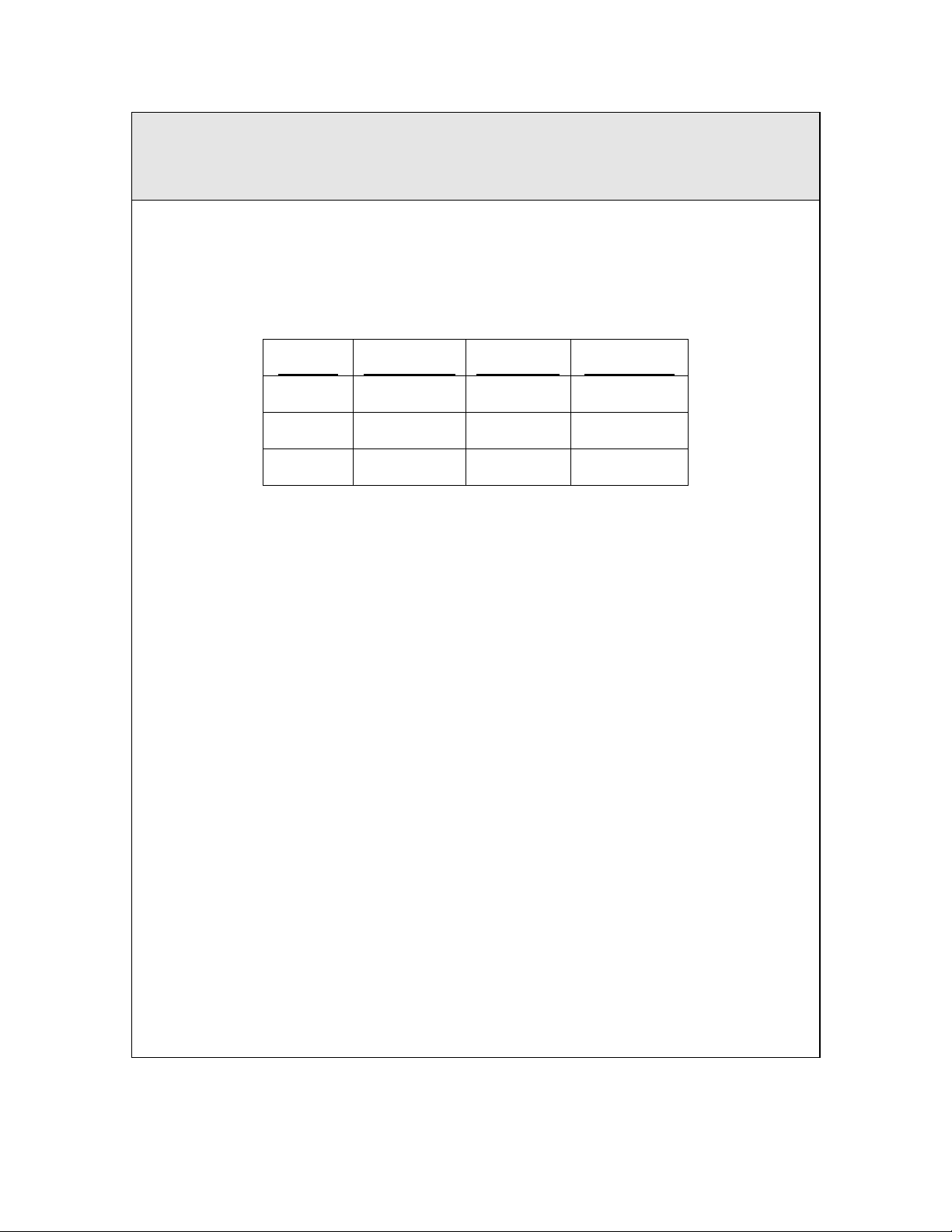

All rolls are supported in antifriction, self-aligning bearings. The diameter of

our series of coating rolls and doctor rolls can be found in the chart below:

Series #

Coating Roll

Doctor Roll

Backup Roll

#5

4”

2-3/4”

4”

#15

6-1/2”

4-3/8”

6-1/2”

#45

8-3/4”

6-5/8”

8-3/4”

Note: Backup rolls are located on “Model C”Roller Coaters Only

Union Roller Coaters are most versatile in that additions or modifications

can be made to accommodate almost any type of coating problem. Many

coaters have been designed to contain deburring rolls, brush rolls, squeegee

rolls, heated or chilled rolls in addition to coating rolls. Coating rolls can be

chrome plated steel or covered with a number of different coverings including

(but not limited to): Neoprene, Mechanical Neoprene, EPDM, Nitrile, Silicone,

Gelatin, Thiokol, Buna N, Aluminum, etc.

Rolls can be spiral or longitudinally corrugated, depending on the type and

amount of coating material used.

In most cases a smooth ground roll will apply the desired amount of coating

material to the substrate being run.

Page 5

SAFETY

SAFETY INTRODUCTION:

Here you will find safety guidelines for use with Union Tool equipment. These

guidelines apply to anyone working with Union Tool equipment, including

operations and service personnel. These guidelines are repeated throughout the

manual, along with specific warnings and cautions not included here. These

safety guidelines cover:

•Safety during Installation;

•Safety during Operation;

•Safety during Servicing;

Failure to follow these recommendations may result in personal injury from

electrocution and/or equipment and property damage.

SAFETY DURING INSTALLATION:

Electrical:

1. A protective electrical ground connection to a reliable earth ground is

essential for safe operation. Without one, all accessible conductive

components (including knobs and controls that appear insulated) can

render an electric shock.

2. A disconnect switch with lockout capability must be provided between the

power source and the equipment.

Page 6

SAFETY

(Continued)

SAFETY DURING INSTALLATION (Continued):

3. The power supply wire gauge and insulation must be sufficient to meet the

power requirements for the machine.

4. Only fuses of the correct type voltage rating and current rating should be

used. Refer to the Union Tool wiring diagram equipment parts list for

fuse recommendations. Using incorrect or non-recommended fuses can

present a fire hazard.

Pneumatic: Union Tool has installed a lockout, three-way, manual valve in

the air supply line to the filter/regulator. This valve makes it

possible to relieve air pressure and lock out the pneumatic system

before undertaking maintenance or repairs.

SAFETY DURING OPERATION:

DO NOT operate Union Tool equipment under the following conditions:

1. Near volatile or otherwise explosive gases or materials.

2. Without the covers, panel and safety guards properly installed.

Page 7

SAFETY

(Continued)

SAFETY DURING OPERATION (Continued):

3. At atmospheric temperatures below 20F (-6C) or above 120F (50C).

4. In drafty areas with the coating rolls unshielded from the draft.

5. NEVER use Union Tool equipment as a ladder or stepping stool.

SAFETY DURING SERVICING:

1. DO NOT perform internal service or adjustment on any equipment unless

another person capable of rendering first aid and resuscitation is present.

2. Only qualified personnel should service Union Tool equipment.

3. To avoid personal injury, never touch exposed connections and

components while power is ON. Dangerous voltages exist at several

points in the equipment.

4. Disconnect, lock out and tag external electrical power before removing

protective panels or replacing electrical components.

5. Remove all jewelry (rings, watches, etc.) before servicing equipment.

6. If possible, stand on a rubber mat when servicing Union Tool equipment.

DO NOT work on equipment if standing water is present. Avoid working in

a high-humidity atmosphere. Cover exposed terminals and work areas

with rubber sheeting to avoid accidental contact while the power is ON.

Page 8

INSTALLATION

Your Union Tool Roller Coater is easy to install.

1. Remove the coater from the skid. Depending on the size, the coater could

be very heavy so please make a note of the shipping weight and use the

proper equipment. Lift from the bottom of the frame. Be sure that the lift forks

are against the frame when lifting the coater from the wooden skid.

2. Place the coater in the chosen position.

3. Level the coater.

4. Make the power drop to the disconnect box. The voltage should be clearly

marked on the front of the disconnect box and on the electrical print inside the

box.

5. Make an air drop to the coater if the coater is equipped with a filter and

regulator. Please do not reduce the size of the lines of the air drop

smaller than the supplied filter and regulator.

Make a visual check between the coating rolls and doctor rolls; look for any

loose objects that may have fallen between the rolls. Check the rotation of the

coating and doctor rolls in the reverse mode. All guards and covers must be in

position for the coater to operate.

Page 9

Location

The machine should be located with due consideration for the movement of

materials in and out of the machine and the ease of movement required by the

operator.

Mounting holes are provided in the "feet" of the machine for the purpose of

leveling. The machine must be on a solid, level surface and a spirit level

should be used longitudinally on the channel at the top of the machine and on

the lateral top section of the frame. The machine must be secured to the floor

by bolts or equal to ensure stable running.

WIRING

Make sure proper wiring is carried out to prevent damage to the circuit. Refer

to packing list or wiring diagram inside the electrical control box. This will

ensure correct voltage to all motors.

MACHINE SHOULD BE GROUNDED FOR SAFETY OF OPERATOR.

Page 10

OPERATING INSTRUCTIONS

Roll Adjustments

The vertical adjustment assembly raises and lowers the upper roll assembly to

accommodate various thickness of substrates being ran. Generally, this upper

roll assembly is the only one that requires vertical adjustments; however, in

special cases the lower roll assembly has been made adjustable. These rolls

should never be allowed to be forced together so as to cause damage to the

surface of the rolls. A handwheel located at one end of the coater connects two

gear box arrangements and is the means of operating this assembly. Turning

this handwheel in the direction as indicated by the tag will adjust the gap

between the upper coating roll and lower coating roll (or lower back-up roll). This

assembly is mounted on top of the machine at the end housing and includes a

coupling to allow the top roll to be adjusted parallel to the bottom roll within a

thousandth of an inch. To parallel the roll, pull the spring-loaded portion of the

coupling back and either turn the single handwheel or turn the shaft to move

either side up and down independently.

NEVER ALLOW COATING ROLLS TO TOUCH. Sharp materials or

burrs should never be run through the machine with rubber rolls. This would cut

& gouge the rolls.

This manual suits for next models

2

Table of contents