Manual Pury 250e Safety Instructions

Manual Pury 250e 2006-06-08 5

1. Safety Instructions

Before start up and use of the Pury 250E, please take time to carefully review

this manual and its contents. Observe all warnings, cautions and notes.

Warning:

Disconnect the main power switch before any service work is carried out.

Before maintenance or repair work on the power or high voltage ignition

equipment, the following points need to be observed.

After switching off the main power wait at least 5 min. for any stored voltage

charge to dissipate to zero.

During start up, service or abnormal conditions there is a danger of a very

small release of unburned gas from the outlet of the system to the atmosphere.

If process gas has any toxic components please follow all personal safety

rules. Any small release of gas during start-up is highly diluted with cooling

air.

All electrical connections to line power must be carried out by a qualified electrician.

The analyzers internal electrical components are wired in accordance with NEC, VDE

and International standards. Check the power supply voltage, details can be found on

the technical data label inside the door.

Only qualified personnel should install the gas connections in accordance with all

local codes and ordinances.

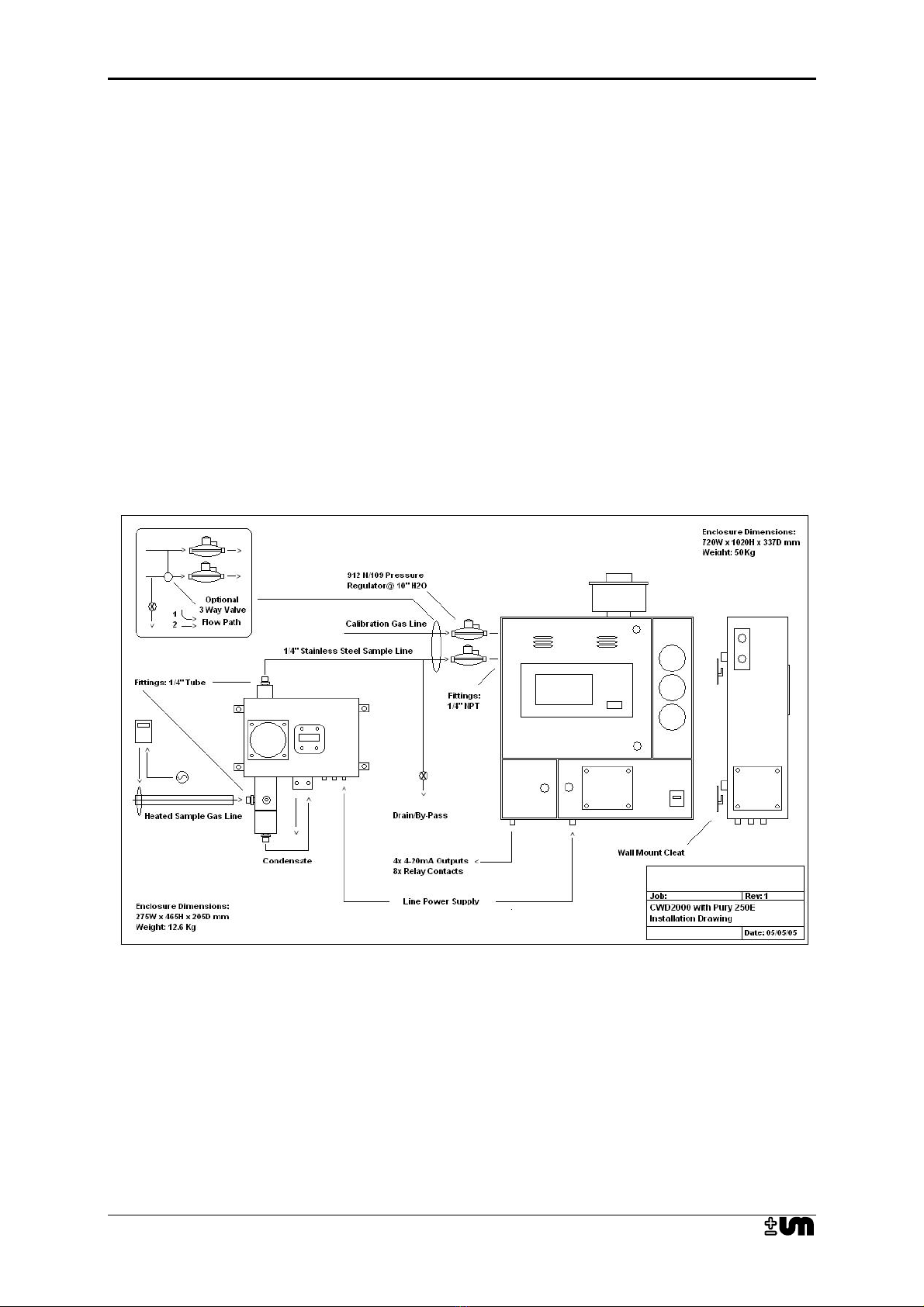

The Pury 250E operates over a specified ambient temperature range. and installing

the unit directly outside is not recommended, since damage may occur from adverse

weather conditions if an outdoor shelter is not used.

Caution:

Caution is necessary during installation because pressurized flammable gases are

connected to the sample conditioner and any installation work performed by the

customer must conform to all applicable local and national codes. All internal sample

gas components have been leak tested at 1.5 times the normal operating pressure

during assembly at the factory. After installation, the entire sample gas system

should be pressurized and tested for leaks before use.

When planning the installation, local site conditions must be taken into account so

consult any hazardous area regulations for applicability.