CONTENTS

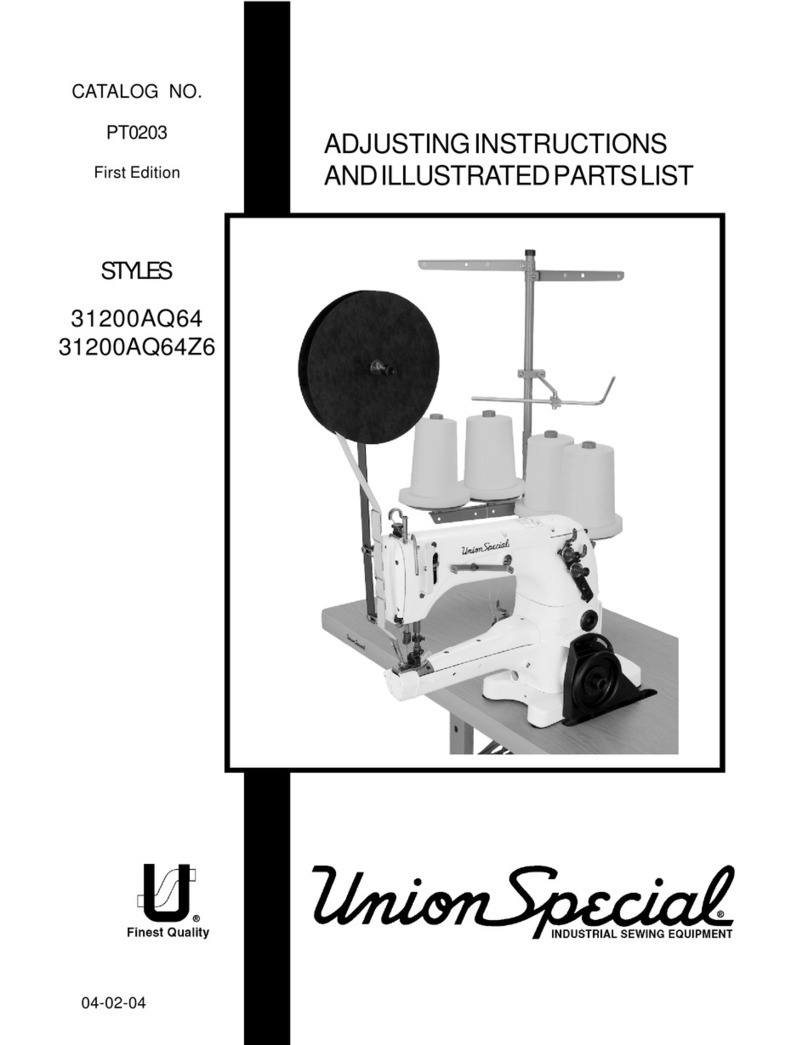

DESC~

I PTION.

............••.••...•.•........

3

INSTALLATION

..•••......••••...•..•...•....

4

LUBRICATION

......•.....••••.............

•. 5

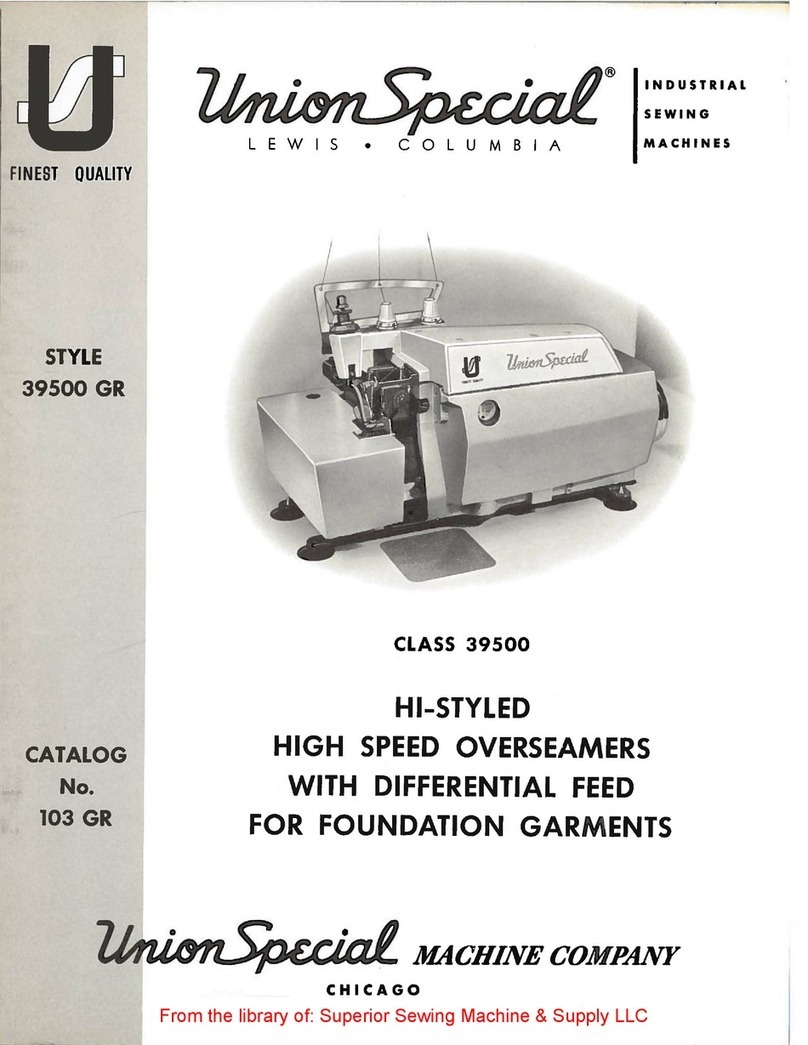

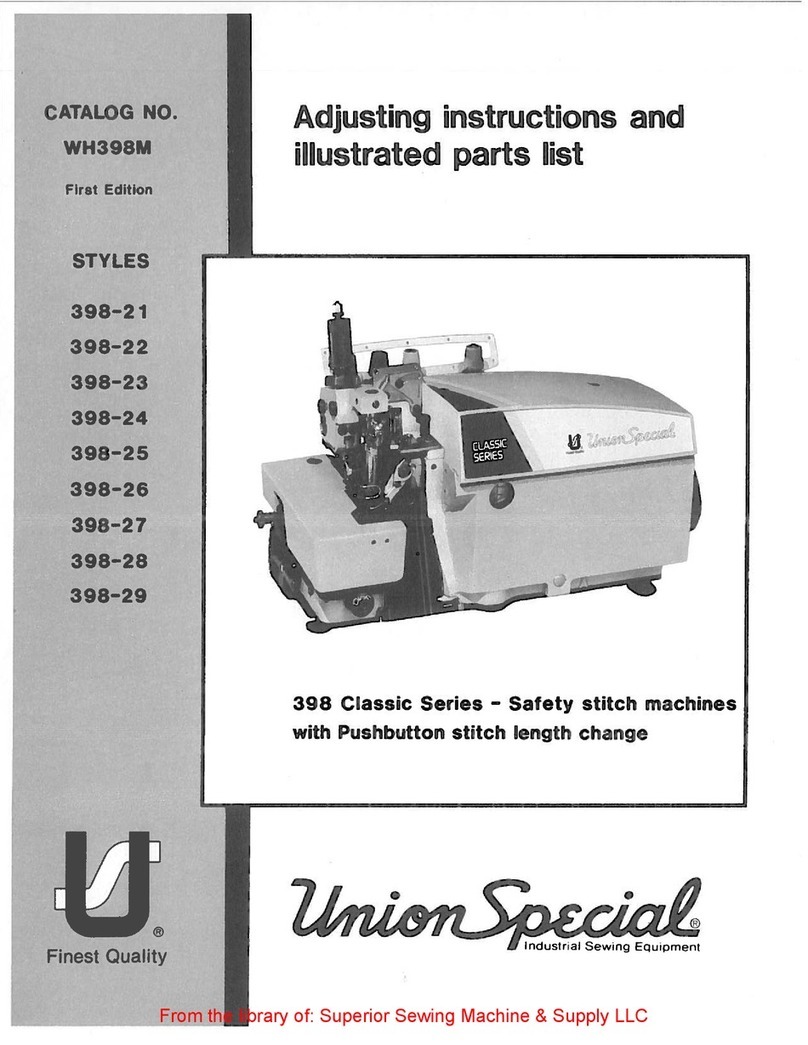

Description

of

Machine

......••.....•..•...•....

3

Genera

I Charocteri

sties

..•.•.......•..••..•..

3

Special

Features

•.•...••••••..•......•.....

3

Feed

Bar,

Height

.....•..•.•••••..•.••..•.....

12

Feed

Dog,

Centralizing

.....•••....•.....••..•.

12

Height

....•.......••....•••.......•....••

12

Lengthwise

Setting

........................

12

Sidewise

Setting

..•..•...•••.•........•...

12

Timing

.••.•.•..

.

...•..•••••..•..••....•.

.

13

Feed

Roll,

Pressure

...........................

9

Installation

..•.......•..•••••••.•..•...•.....

4

Loop

Deflector

••.••.••..•.••.••..•.........••

13

Looper, Positioning

•.•..••.••.•.•..•..•.....•

•

14

Lengthwise

Setting

.....•.••.•..•.....•.•..

.14

Sidewise

Setting

•..•..•.••••.•........•....

14

Timing

•.•.•.•..•..•.•.•••••..........•.••

15

Lubrication

....•..•.••.••.•.••••..•..•........

5

Arm

Shaft

.••..••..•..•..•••••..•.•...•.••..

5

Bed

Shaft

...•..•.•..•.•.•••......•.......•.

5

Other

Points

•..........•••.•.•..••••.......

5

OPERATOR

INFORMATION

..................

S-8

ADJUSTMENTS

............................

8-17

IHDEX

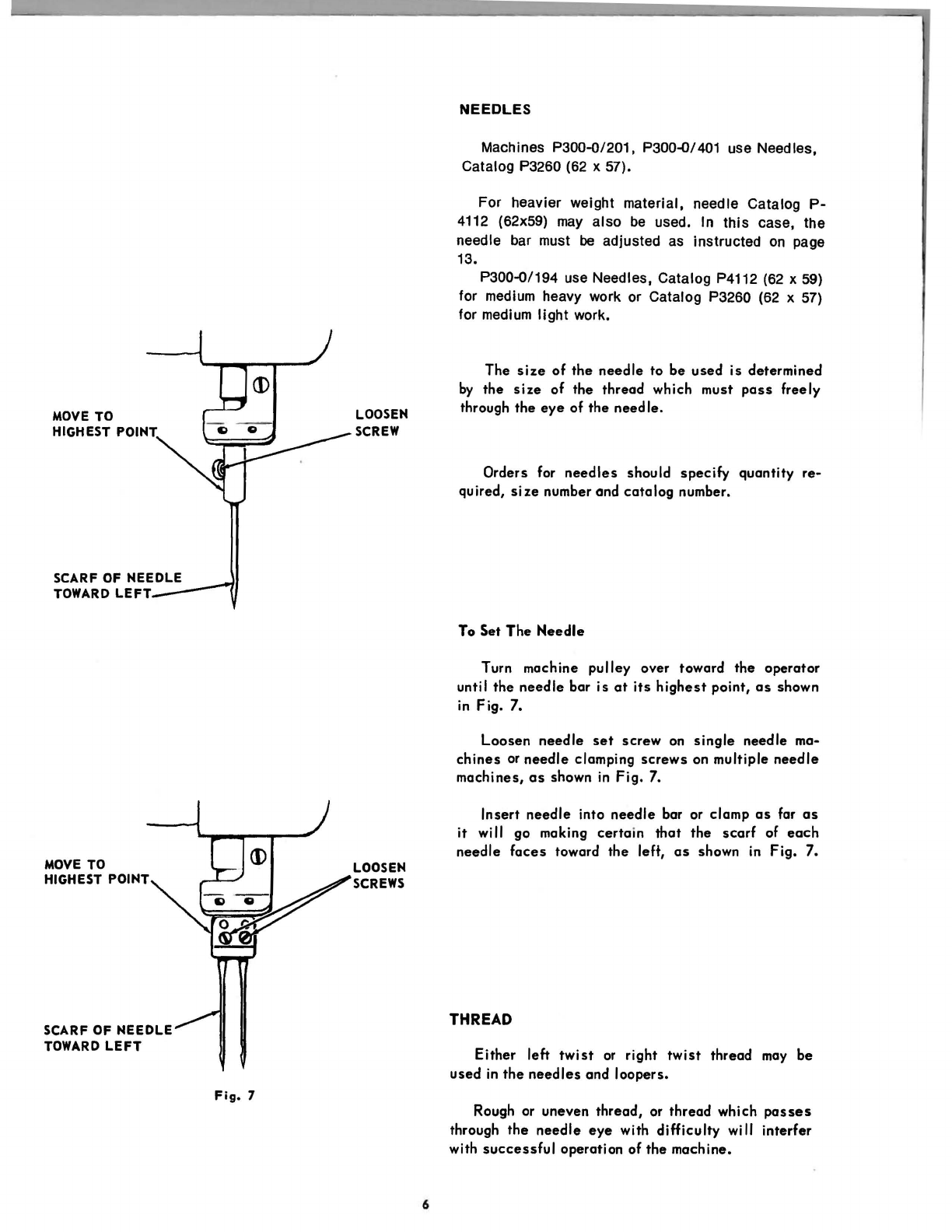

Needles

•.•....••..•.........•.••.••.....•••..

6

Setting

•...•.••.••..•..•........••••..•••..

6

Needle Bar, Height

•.•.••..•..•....•...••..••••

14

Needle Bar, Position

••.•.•...•....••.•...•••••

13

Needle Guard,

.•......•...••...•••.•..•..•••..

15

Presser

Bar, Height

•..••••.....•..•....•..••••

11

Presser

Foot, Pressure

......................

8, 9

Speed

•.•.•..••.•.....•.•.•••.•.•••...•••.••..

5

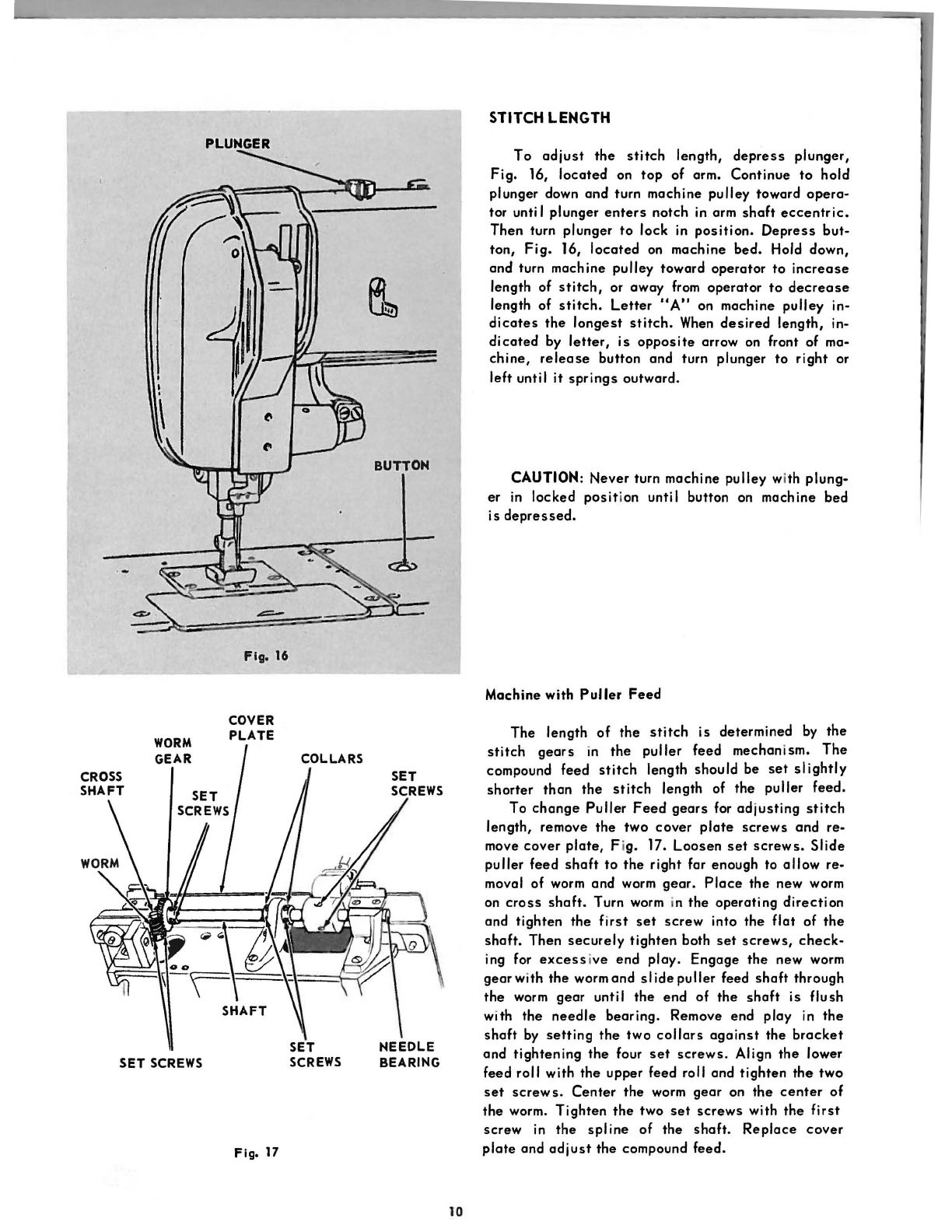

Stitch Length

.•.••..•..•.•..••.•..••.•••.•••.

.10

Spreader, Positioni

ng

••.•.•.....•••.•..••••••••

16

Lengthwise Setting

•.......•..•..•.•••..•••

16

Sidewise and Height Setting

..•...•......••••

16

Toke-up, Adjustment

.•..•..•.........••.•..•••

17

Looper Thread

.••.•..••.•.•.•••.•••.•.••••

17

Needle Thread

.•..••••....•.••.•...••..•••

17

Tension

.•..•.••.••....•..•....••.••.••.•.••.•

8

Releaser

...•.•..••.•.••..•.•..••..•.••.••

17

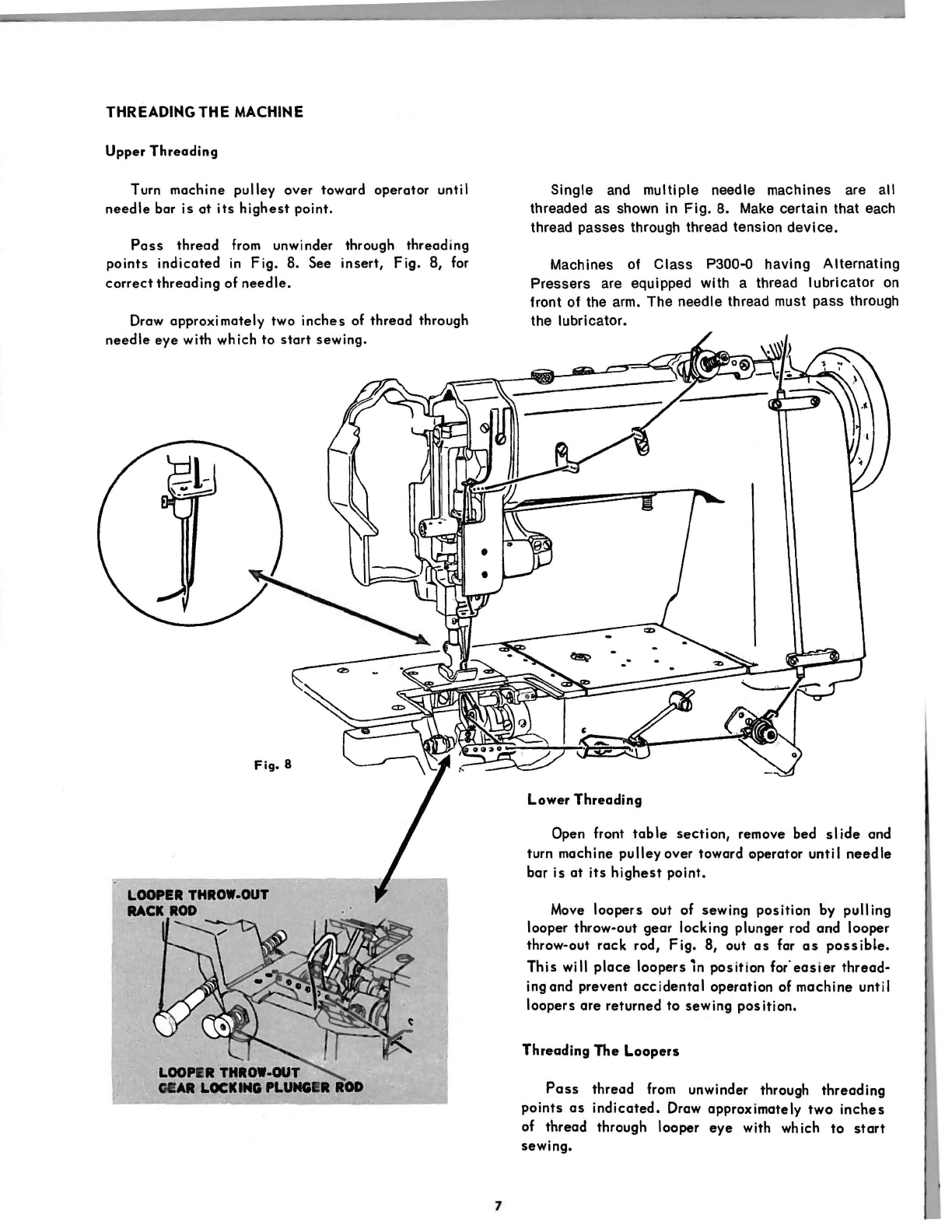

Threading

.•..•......••.•..•..••..••..••..••••

7

Upper

.•.....••.•.....•.....•.•..••.••.••••

7

Lower

••••.•••....••.••..••••••.••••...•••

7

From the library of: Superior Sewing Machine & Supply LLC