From the library of: Superior Sewing Machine & Supply LLC

IDENTIFICATION

OF

MACHINES

Each

UNION

SPECIAL

machine

is

identified

by a

Style

number which

is

stamped

into

the

name

plate

on

the

machine.

Style

numbers

are

classified

as

standard

and

special.

Standard

Style

numbers

have

one

or

more

letters

suffixed,

but

never

contain

the

letter

"Z".

Example:

"Style

63400 A".

Special

Style

numbers

contain

the

letter

"Z".

When

only

minor

changes

are

made

in

a

standard

machine,

a "Z"

is

suffixed

to

the

Standard

Style

number.Example:

"Style

63400 AZ".

Styles

of

machines

similar

in

construction

are

grouped

under

a

class

number which

differs

from

the

style

number,

in

that

it

contains

no

letters.

Example:

"Class

63400

11

•

APPLICATION

OF

CATALOG

This

catalog

applies

specifically

to

the

Standard

Styles

of

machines

as

listed

herein.

It

can

also

be

applied

with

discretion

to

some

Special

Styles

of

machines

in

this

Class.

Refer-

ence

to

direction,

such

as

right,

left,

front,

back,

etc.,

are

given

from

the

operator's

posi-

tion

while

seated

at

the

machine.

Operating

direction

of

the

handwheel

is

toward

the

operator.

STYLES

OF

MACHINES

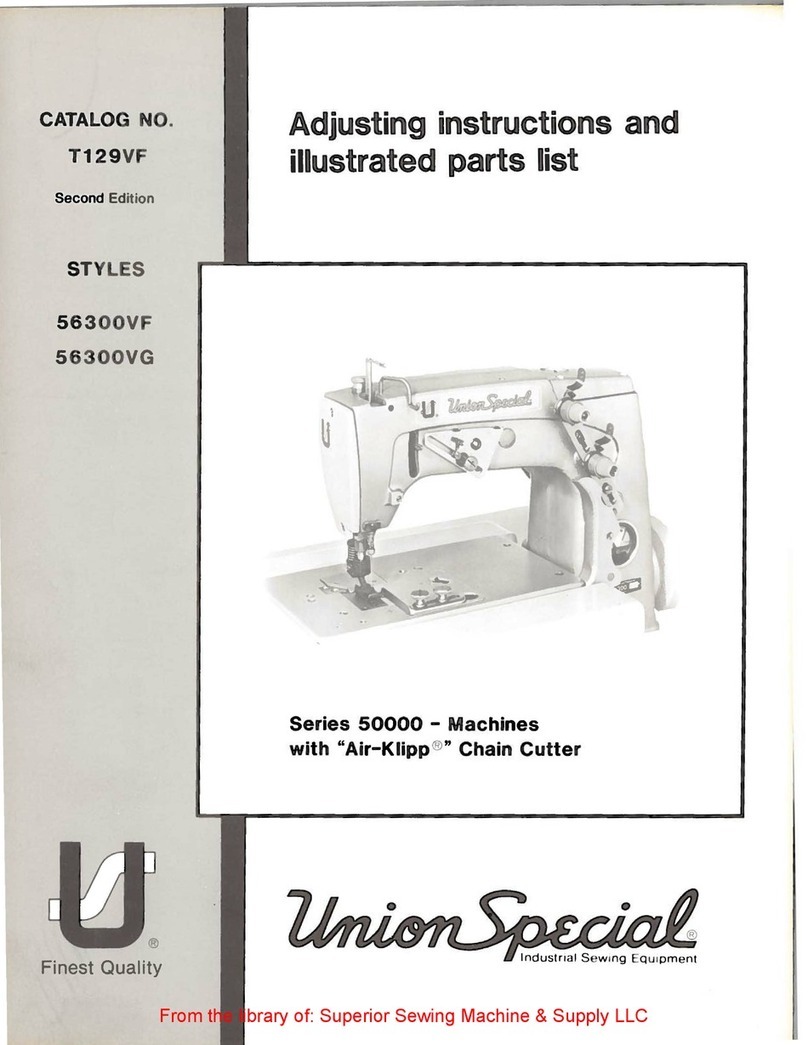

High Speed

Streamlined

Long

Arm

Lockstitch

Machines,

One

Needle,

Light,

Medium

and Heavy

Duty,

Drop

Feed,

Rotary

Hook,

Horizontal

Hook

Shaft,

Push

Button

Stitch

Regulator,

Stitch

Length

In-

dicator,

One

Reservoir

Enclosed

Automatic

Lubricating

System, Head

Oil

Siphon,

Adjustable

Hook

Oil

Control,

Automatic

Head

Oiling,

Needle

Bearing

Adjustable

Feed

Eccentric,

Needle

Bearings

for

Take-up

Lever

and

Needle

Bar

Driving

Link,

Feed Timing on Lower Main

Shaft,

Maximum

Work

Space

to

Right

of

Needle

Bar 11

1/8

Inches,

*63400 A

For

miscellaneous

plain

seaming

operations

on

light

and medium

weight

work,

1

9/64

inch

needle

bar

travel.

Type 183

GXS

or

183

GYS

needle.

Specify

presser

foot,

throat

plate,

feed

dog,

stitches

per

inch,

thread

size,

needle

type

and

size,

attachments

and

guides.

63400 B

For

miscellaneous

plain

seaming

operations

on medium and medium

heavy

weight

work,

1

13/64

inch

needle

bar

travel.

Type 180

GXS

or

180

GYS

needle.

Specify

presser

foot,

throat

plate,

feed

dog,

stitches

per

inch,

thread

size,

needle

type

and

size,

attachment

and

guides.

*

DISCONTINUED

-

In

most

instances,

component

parts

can

be

ordered

for

customer

repair.

NEEDLES

Each

needle

has

both

a

type

and

size

number. The

type

number

denotes

the

kind

of

shank,

point,

length,

groove,

finish

and

other

details.

The

size

number, stamped on

the

needle

shank,

denotes

largest

diameter

of

the

blade

measured

across

the

eye.

Collectively,

the

type

number

and

the

size

number

represent

the

complete

symbol.

Needle

Type 180

GXS

or

180

GYS

is

recommended

for

Style

63400

Band

needle

Type 183

GXS

or

183

GYS

is

recommended

for

Style

63400

A.

Their

description

and

the

sizes

available

are

listed

below.

Type

No.

180

GXS

180

GYS

183

GXS

183

GYS

Description

and

Sizes

Round

shank,

round

point,

lockstitch,

short

length,

ball

eye,

single

groove,

wide

angle

groove,

struck

groove,

deep

spot,

ball

point,

chromium

plated

-

sizes

075/029, 080/032, 090/036,

100/040,

110/044, 125/049, 140/054,

150/060.

Round

shank,

round

point,

lockstitch,

short

length,

ball

eye,

single

groove,

wide

angle

groove,

struck

groove,

deep

spot,

chromium

plated

-

sizes

075/029,

080/032,

090/036,

100/040,

110/044,

125/049,

140/054,

150/060.

Round

shank,

round

point,

lockstitch,

extra

short

length,

ball

eye,

single

groove,

wide

angle

groove,

struck

groove,

deep

spot,

ball

point,

chromium

plated

-

sizes

025,

075/029,

080/032,

090/036,

100/040,

110/044.

Round

shank,

round

point,

lockstitch,

extra

short

length,

ball

eye,

single

groove,

wide

angle

groove,

struck

groove,

deep

spot,

chromium

plated

-

sizes

028,

080/032, 090/036,

040,

044.

3