OILING

(Continued)

Machine

is

automatically

lubricated.

No

oiling

is

necessary,

other

than

keeping

main

reservoir

filled.

Check

oil

daily

before

the

morning

start.

Add

oil

as

requi

r

ed.

Drain

plug

screw

is

located

at

back

of

machine

near

bottom

edge

of

base.

It

is

a

magnetic

screw

designed

to

accumulate

possible

foreign

materials

wh

i

ch

may

have

entered

the

crank

case.

It

should

be

removed

and

cleaned

periodically.

NEEDLES

Each

Union

Special

needle

has

both

type

and

size

number.

The

Type

number

denotes

the

kind

of

shank,

point,

length,

groove,

finish

and

other

details.

The

size

number,

stamped

on

the

needle

shank,

denotes

largest

diameter

of

blade,

measured

in

thousandths

of

an

inch,

midway

between

shank

and

eye.

Collectively,

type

and

size

number

represent

the

complete

symbol

which

is

given

on

the

label

of

all

needles

packaged

and

sold

by

Union

Special.

39500

AB,

AC

and

AE

use

a

curved

blade

needle.

The

standard

needle

for

these

styles

is

Type

154

GCS.

It

is

a

slabbed

shank,

round

point,

•

046

inch

double

slab,

standard

length,

curved

blade,

double

groove,

struck

groove,

spotted,

chromium

plated

needle

in

sizes

025,

027,

029,

032.

To

have

needle

orders

promptly

and

accurately

filled,

an

empty

package,

a

sample

needle,

or

the

type

and

size

number

should

be

forwarded.

Use

description

on

label.

A

complete

order

would

read:

"1000

Needles,

Type

154

GCS,

Size

025".

Selection

of

proper

needle

size

is

determined

by

size

of

thread

used.

Thread

should

pass

freely

through

needle

eye

in

order

to

produce

a

good

stitch

formation.

Success

in

the

operation

of

Union

Special

machines

can

be

secured

only

by

use

of

needlespackagedunderourbrandname,

~

which

is

backed

by

a

reputation

for

producing

highest

quality

needles

in

materials

artd

workman-

ship

for

more

than

three-quarters

of

a

century.

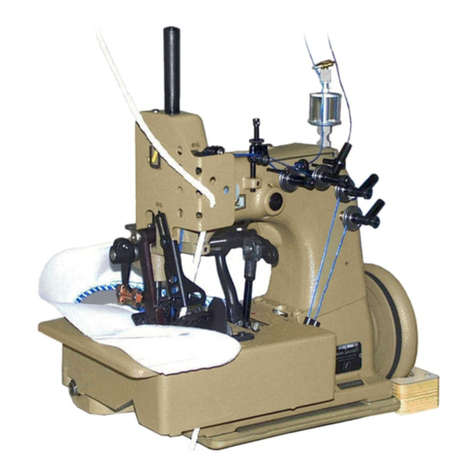

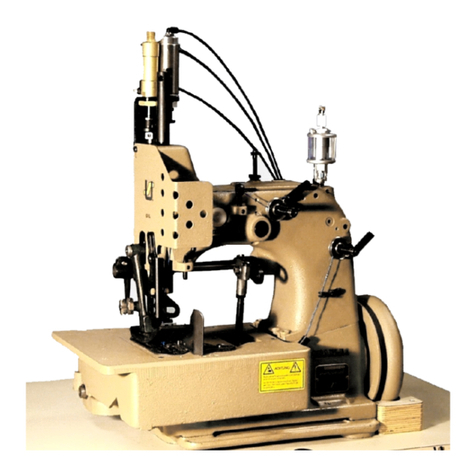

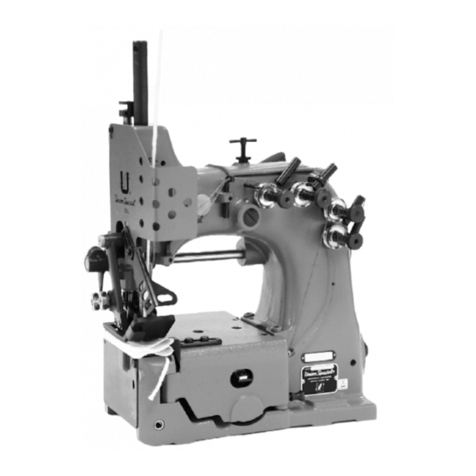

CHANGING

NEEDLES

Release

pressure

on

presser

foot

by

turning

presser

foot

release

bushing

(N,

Figs.

1

and

2),

and

swing

presser

arm

(E)

out

ofposition.

Turnhandwheel

in

the

operating

direction

until

needles

are

at

their

lowest

point

of

travel.

Using

hexagonal

socket

wrench,

No.

21388

AU,

furnished

with

machine,

loosen

needle

clamp

nut

about

1/4

turn.

Again

turn

handwheel

until

needle

s

are

at

high

position;

withdraw

needles.

To

replace

needles,

leave

needle

holder

at

high

position

and,

with

the

flats

to

the

left,

insert

needles

in

holder

until

they

rest

against

the

stop

pin.

Keeping

needles

in

this

position,

turn

handwheel

until

holder

is

aga

in

at

its

low

point

of

travel,

then

tighten

nut.

Return

presser

arm

(E)

to

position;

re-lock

presser

foot

bushing

(

N).

4

From the library of: Superior Sewing Machine & Supply LLC