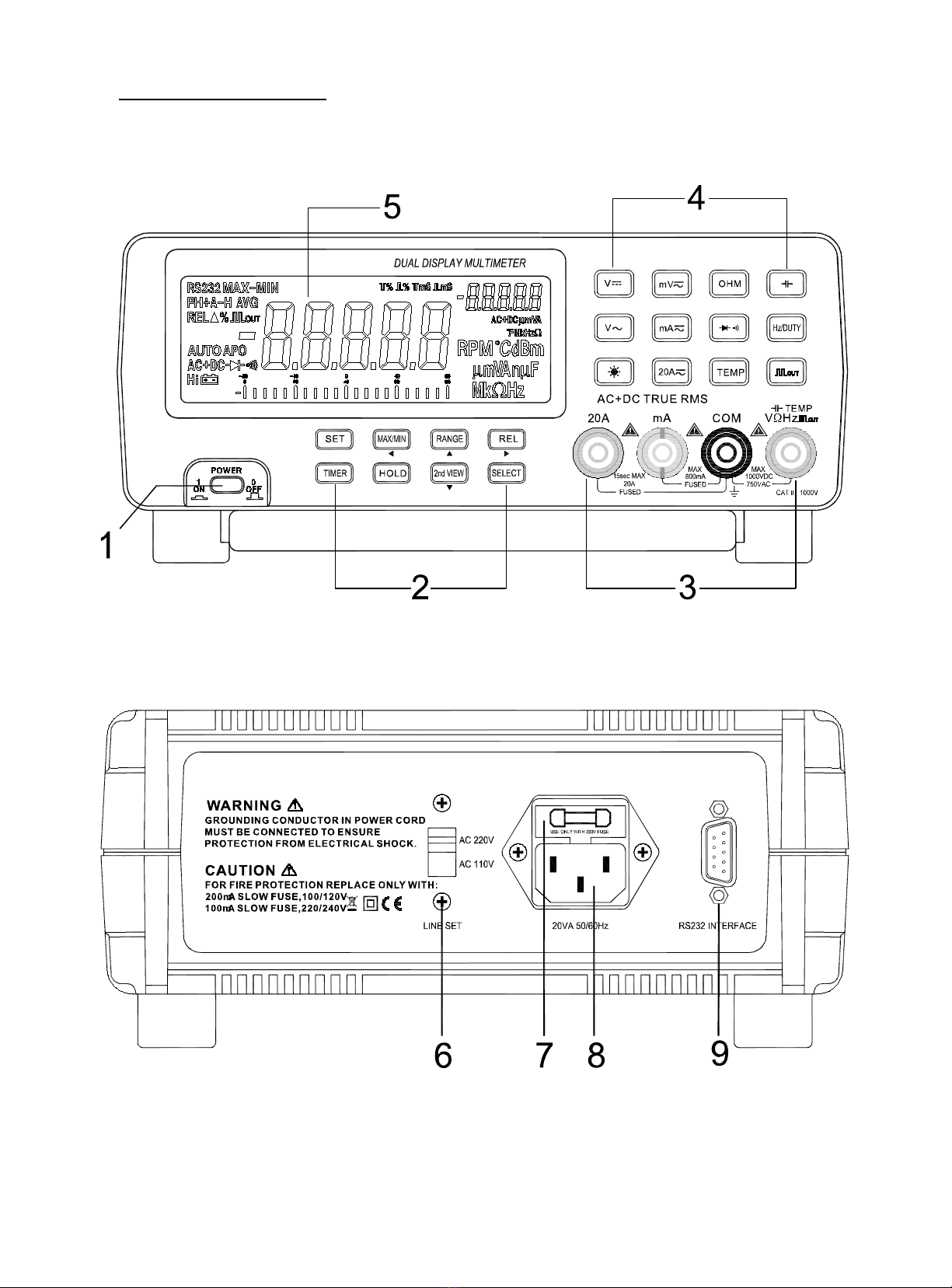

1. Power switch: turns the meter on or off

2. Auxiliary keys: SELECT, RANGE, SET, MAX/MIN, Timer/RS232/HOLD/2nd VIEW/ REL

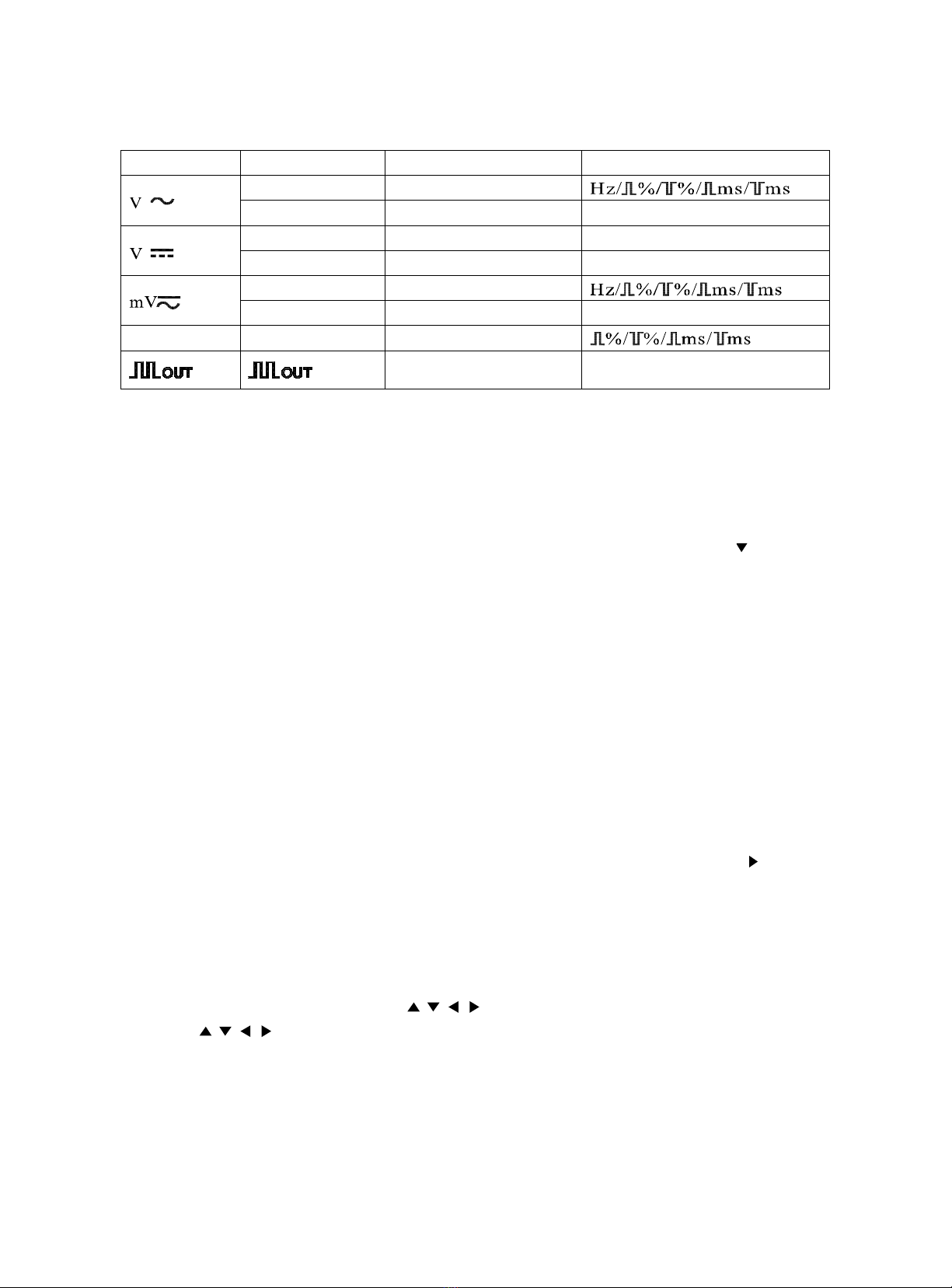

SELECT: Selects measurement mode

RANGE: Selects measurement range. The meter is default at auto range mode.

SET:

When the SET button is in operation, the RANGE button is used as a moving up button ( ), the 2nd VIEW

button as a moving down button ( ), the MAX/MIN as a moving left button ( ), and REL

as a moving

right ( ). In this case, the RANGE, 2nd VIEW, MAX/MIN and REL

buttons’ original functions are

disabled. buttons can be used to enter and adjust the setting values.

Press SET button for at least 2 seconds to start the backlight. Press this button again to turn off the backlight.

The backlight can auto off if this button is not engaged within 30 seconds.

MAX/MIN:

Presses this button to enter the dynamic record mode, with maximum record period of 36 hours.

In the dynamic record mode, the meter automatically records the maximum value (MAX), minimum value

(MIN), difference value (MAX-MIN) and calculate the average value (AVG) of all readings. Press this button

to cycle MAX, MIN, AVG, MAX-MIN on the secondary display.

Pressing this button for at least 2 seconds, the meter returns to auto range.

Timer/RS232:

TIME:

TIMER function is enabled only in the REL△andMAX/MIN measuring mode.

Press TIMER key to start the secondary display for counting time. Press TIMER key again to turn off the

counting time display.

When the secondary display is display counting time, press key SELECT to enter Beeper setup for setting up

a timer for beeper. Then, press key REL

( ), MIX/MIN ( ), RANGE ( ), 2nd VIEW ( ) to input the

time. Next press key TIMER to validate the new time data. When the counting time exceeds the preset time,

the beeper sounds.

In the above two modes, press key HOLD to stop timer function and turn off secondary display, but the

preset time remains unchanged.

The time is display in the format of 8.88.88 on the secondary display. The max.counting time is 9.59.59

RS232:

Pressing this button for at least 2 seconds, the RS232 remote control is enabled for PC control and

communication with other instruments. The LCD display “RS232’

Auto power off function is disabled in this RS232 programmable mode.

Pressing this button for at least 2 seconds again to exits this mode and return to normal mode.

HOLD:

Pressing this button, the meter enters auto data hold mode and “A-H” is displayed on the LCD.

The data hold mode allows users to hold the displayed value while the analog bar graph shows the current

reading.

Pressing this button again, the meter enters Peak+ hold mode and a “PH+” appears on the LCD display.

Pressing this button again, the meter enters Peak- hold mode and a “PH-” appears on the LCD display.

Pressing this button for at least 2 seconds, the meter exits HOLD mode and return to normal mode.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com