Table Of Contents

Introduction ...........................................................................................................................................1

Thank You..................................................................................................................................1

System Requirements ...............................................................................................................1

How It Works ..................................................................................................................................... 2-3

Installation ....................................................................................................................................... 4-10

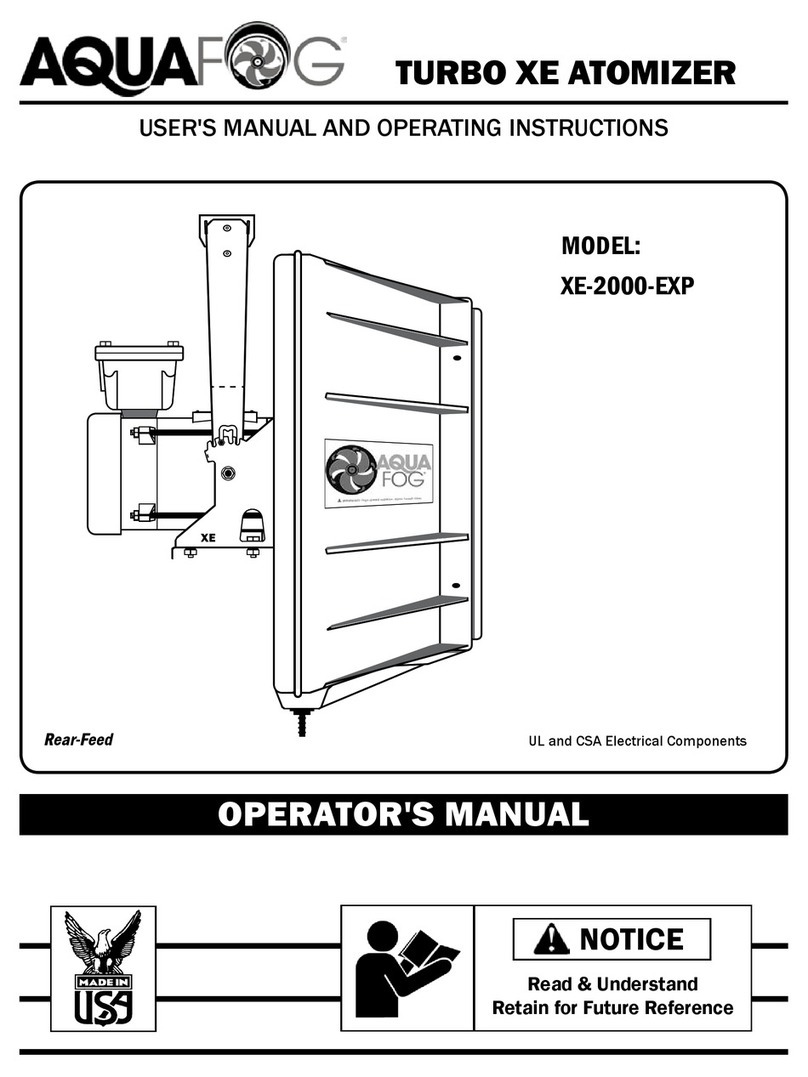

Mounting....................................................................................................................................4

Dimensions ......................................................................................................................4

Articulating Arm................................................................................................................4

Adjustable Magnet Mount ................................................................................................4

Modular Mounting System ...............................................................................................4

Modular Mounting System Assembly .................................................................................... 5-6

Fluid & Air Connections ....................................................................................................... 7-10

4210 Series (Direct Operation) ........................................................................................7

4210 Series (Daisy Chain Operation) ..............................................................................8

4210 Series (Manual Valve Operation) ............................................................................9

4230 Series (Remote Operation)...................................................................................10

Startup & Operation ..................................................................................................................... 11-13

Preliminary...............................................................................................................................11

At The Nozzle (4210 Series Only) .................................................................................11

At The Valve Stack (4230 Series Only)..........................................................................11

Prime The System ............................................................................................................. 12-13

Ensure Air Is Connected ................................................................................................12

Ensure Fluid Is Connected ............................................................................................13

Adjust The Spray Pattern ........................................................................................................13

Adjust The System For Pressure Drops ..................................................................................13

Troubleshooting ........................................................................................................................... 14-15

Rebuild Kit Instructions ............................................................................................................... 16-19

Appendix A: 4210 Series Drawing ....................................................................................................20

Appendix B: 4230 Series Drawing ....................................................................................................21

Appendix C: 4210 Series Part Numbering Scheme .........................................................................22

Appendix D: 4230 Series Part Numbering Scheme .........................................................................23

Appendix E: Low Volume Spray Nozzle Spray Patterns .................................................................24

Notes....................................................................................................................................................25