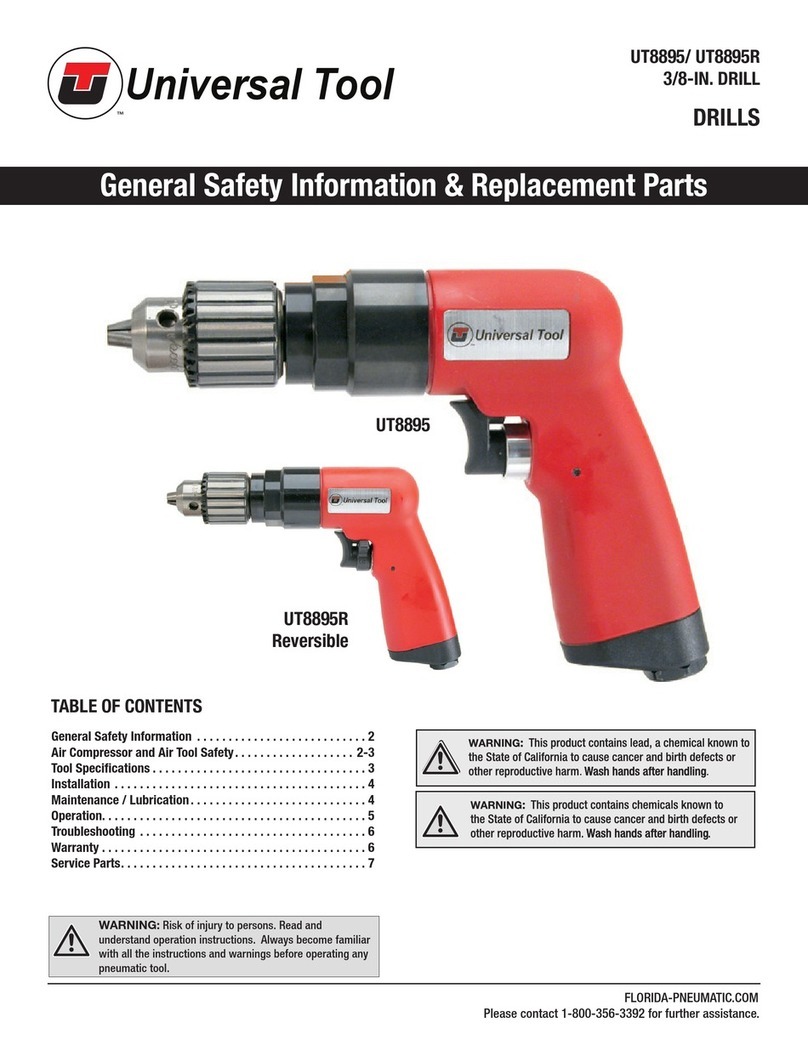

UT8836R

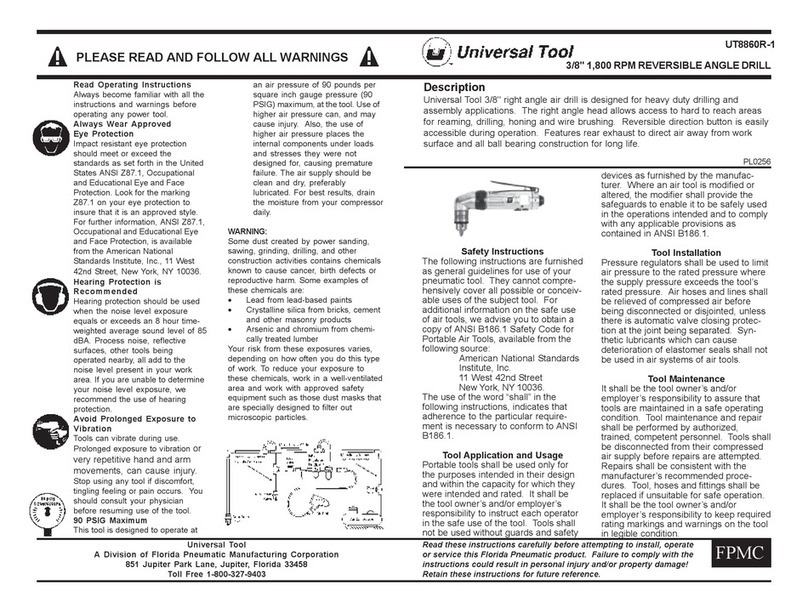

Installation

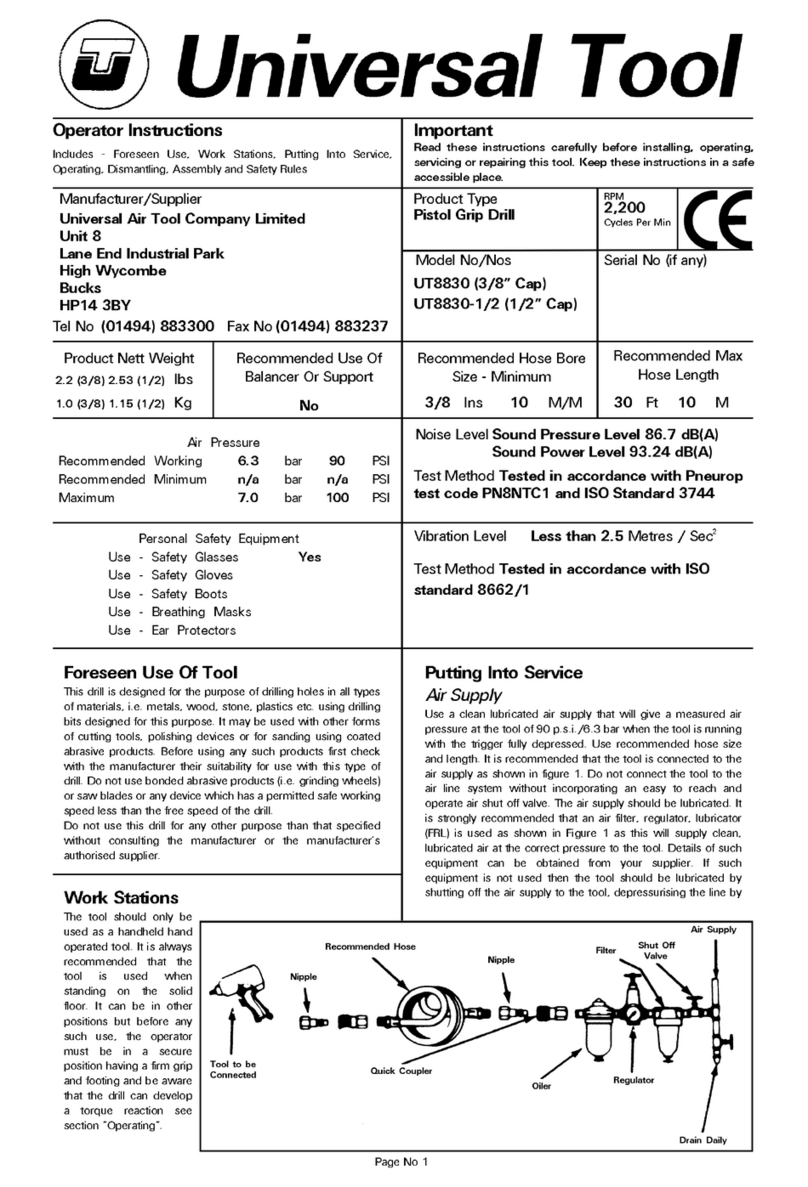

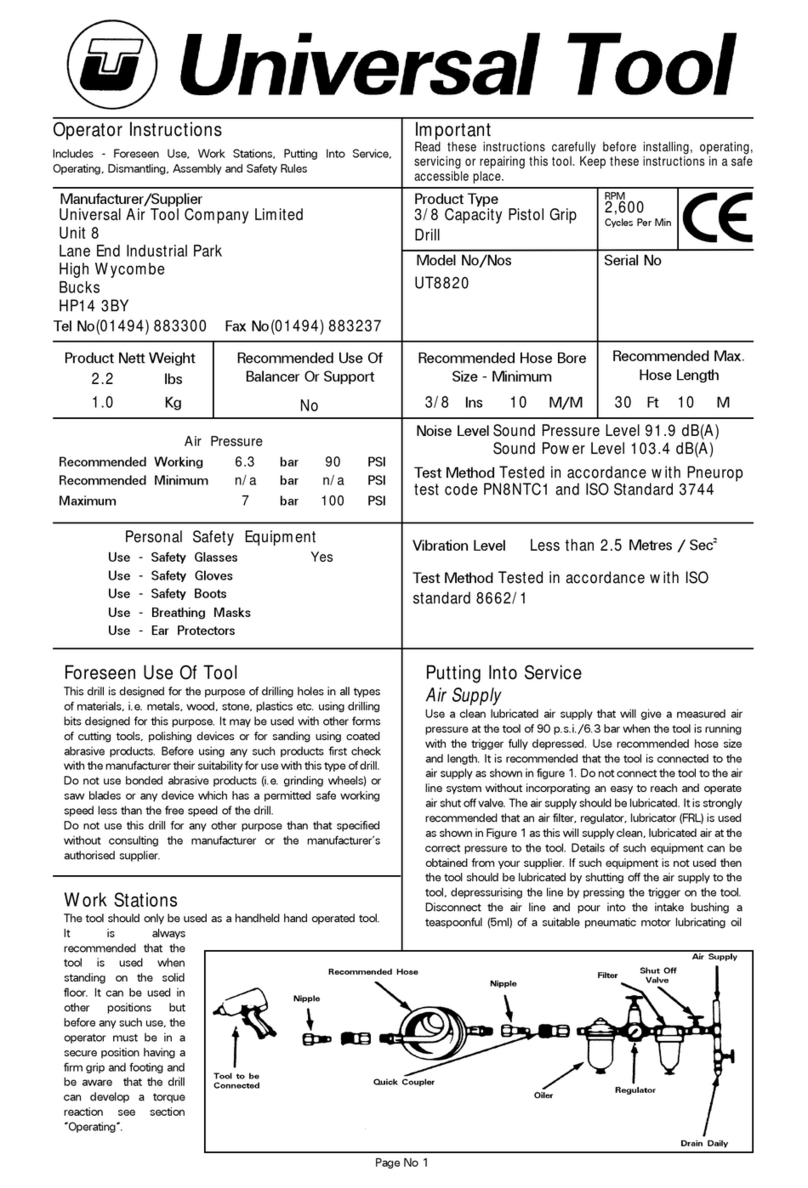

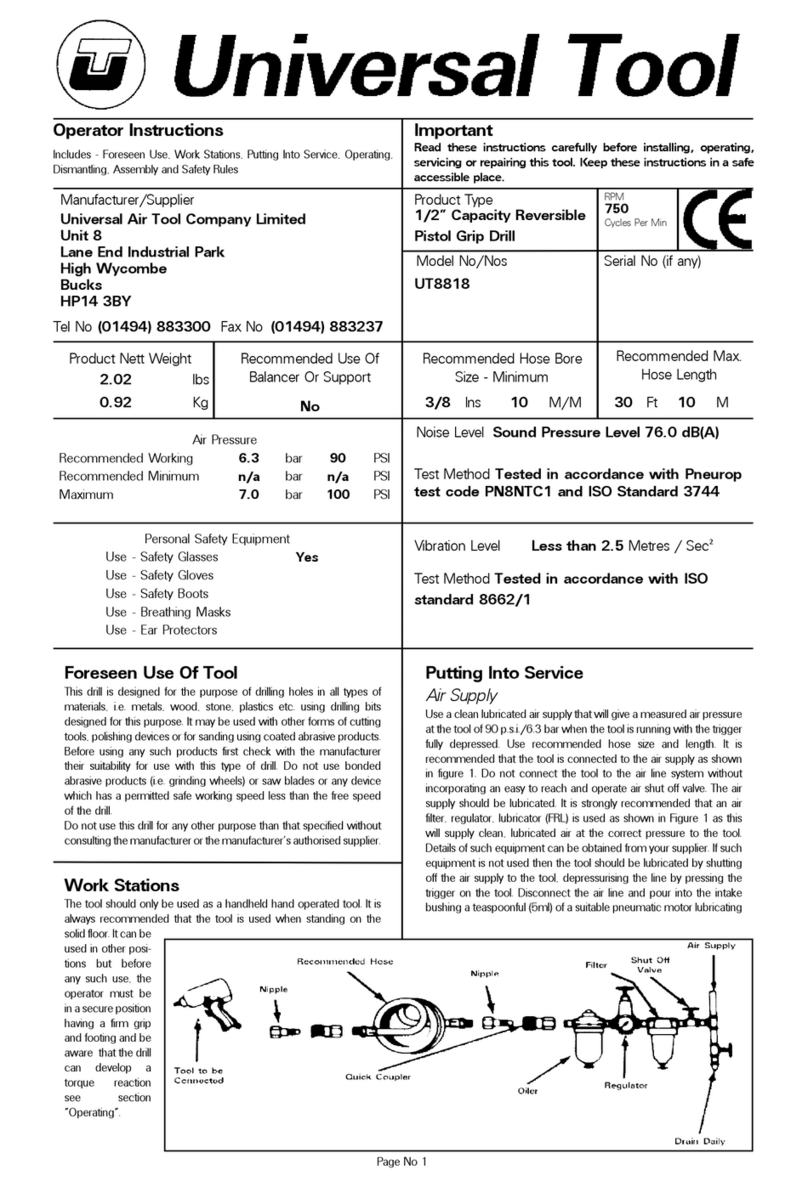

The UT8836R is designed to operate with 90 PSIG. Lower pressure

(below 90 PSIG) will reduce performance of the tool while higher air

pressure (over 90 PSIG) raises the performance of the tool beyond its

rated capacity and could cause serious damage to tool and

operator.Always use clean dry air. Excessive moisture and dirt will

greatly reduce the life of any air tool. We recommend the installation of

an in-line filter-regulator-lubricator as close to the tool as possible. A

3/8" air hose is required up to a length of 8 ft. If more length is

required, a 1/2" air hose should be connected to the 3/8" hose to

ensure the tool has the necessary air supply. Be sure all hoses and

fitting are the correct size and tightly secured.

2

Lubrication

1. An automatic in-line filter-regulator-lubricator is recommended to

increase tool life and keeps the tool operating properly. The in-

line lubricator should be regularly checked and filled with Marvel

air tool oil or equivalent. Proper adjustment of the in-line lubricator

is performed by placing a sheet of paper next to the tool exhaust

ports and holding the throttle open approximately 30 seconds.

(The lubricator is properly set when a light stain of oil collects on

the paper). Excessive amounts of oil should be avoided as it will

decrease tool performance.

2. In the event that it becomes necessary to store the tool for an

extended period of time (overnight, weekend, etc.), it should

receive a generous amount of lubrication at that time. The tool

should be run for approximately 30 seconds to ensure oil has

been evenly distributed throughout the tool. The tool should be

stored in a clean and dry environment.

3. Recommended lubricants:

Use Marvel Air Tool Oil or any other high grade turbine oil

containing moisture absorbents, rust inhibitors, metal wetting

agents and an EP (extreme pressure) additive.

Caution - If the drill jams in the work, release

throttle immediately. Disconnect the drill before removing

bit and determine cause of trouble. Do not attempt to free

the bit by starting and stopping the motor.

Reversible Drill

Pre-Operation

After properly setting up the tool, air lines, air supply and work area,

the tool is ready to use. For best results, before using tool, operators

should take time to familiarize themselves with the feel and operation of

the tool's design and features.

Before the tool is connected to the air supply, clear the air hose of

accumulated dust and moisture. When removing a tool for service or

changing accessories, make sure the tool is disconnected or air line is

shut-off and drained of air. This will prevent the tool from operating if

the throttle is accidently engaged.

Lubricate tool regularly and properly. Always wear safety equipment

during operation. Check condition of tool and accessories before each

use.

Operation

The reverse lever is located on the left side of the pistol grip handle. It

is labeled as “F” for forward (tightening or drilling) and “R” for reverse

(loosening or removing). Do not change direction while tool is running.

Locate center of new hole by using a center punch. Place drill bit tip in

punch mark. Hold drill square with work and start motor. Apply steady,

even pressure. Do not force. Too much pressure can cause bit to

break or overheat. Too little pressure will keep bit from cutting and

cause it to overheat.

Warning - Never operate tool without inspecting

and installing the proper accessories. Doing so may result

in personal injury or damage to the tool. Use only accesso-

ries rated at or above RPM of tool.

Reduce pressure just before bit cuts through the work. When bit has

penetrated work and is spinning freely, take it from the work while the

motor is running, then release throttle.

WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contains chemicals known to cause

cancer, birth defects or reproductive harm. Some examples of these

chemicals are:

•Lead from lead-based paints

•Crystalline silica from bricks, cement and other masonry products

•Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals,

work in a well-ventilated area and work with approved safety

equipment such as those dust masks that are specially designed to

filter out microscopic particles.