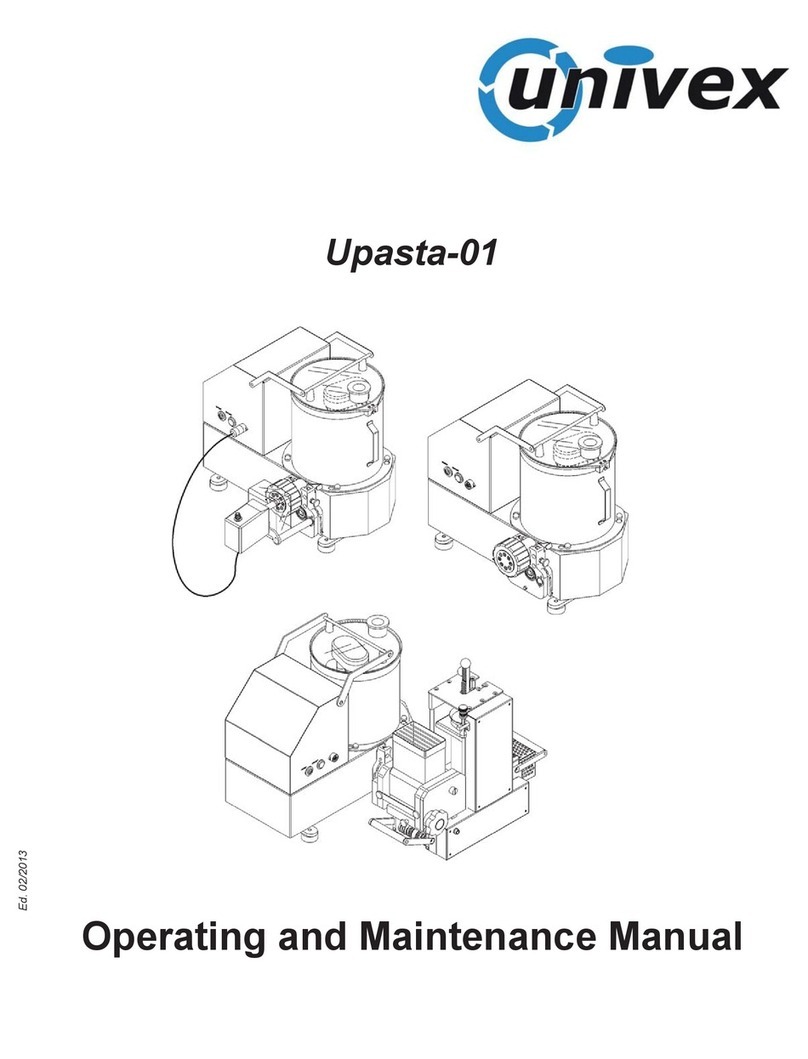

Univex UPASTA Operating instructions

1

Operating and Maintenance Manual

Ed. 001 12/2020

Pasta machine

UPASTA

2

3

CONTENTS

1. Delivery and warranty 4

1.1 Foreword

1.2 Storing and using this manual

1.3 Warranty

1.4 Machine description

1.5 Intended use

1.6 Improper use

1.7 Specific equipment details

1.7.1 Warning and danger signs

1.8 Guards and safety devices

1.9 Work position

2. Technical specifications 10

2.1 Main parts

2.2 Technical characteristics

2.3 Machine dimensions and weight

2.4 Wiring diagrams

2.4.1 Single phase wiring diagram

3. Controls and indicators 13

3.1 List of controls and indicators

4. Factory testing, shipping, delivery and installation 14

4.1 Factory testing

4.2 Delivery and handling

4.3 Installation

4.3.1 Disposal of packaging

4.3.2 Handling the machine

4.4 Electrical connections

4.4.1 Single-phase machine

5. Start-up and shutdown 15

5.1 Verification of the correct electrical connection

5.2 Verification of the presence and efficiency of guards

and safety devices

5.3 Verification of the efficiency of the emergency stop button

5.4 Machine start-up

5.5 Machine shutdown

6. Using the machine 16

6.1 Safety instructions

6.2 Dough preparation

6.3 Extrusion

7. Maintenance 17

7.1 Safety instructions

7.2 Lubrication

7.3 Cleaning the machine

7.3.1 Removing the accessory tools

7.3.2 Removing the bowl

7.3.3 Reassembling the bowl

8. Malfunctions and remedies 19

8.1 Malfunctions: causes and remedies

4

1 - Delivery and warranty

1.1 - Foreword

WARNING!

The symbols used in this manual draw the reader’s attention to points and

operations that are hazardous to the operator’s personal safety or that risk

damaging the machine.

Do not use the machine unless you have read and properly understood these

notes.

WARNING!

For reasons of clarity, some of the illustrations appearing in this manual show the

machine or parts of it with its panels or guards removed.

Never use the machine in this condition; only use it when it is fully equipped with

the guards and in good working order.

The manufacturer forbids the reproduction, even partial, of this manual or the use

of its contents for purposes other than those expressly allowed.

Any breach in this regard shall be punishable by law.

1.2 - Storing and using this manual

This manual uses text and illustrations to familiarise users with the machine and

explain the instructions and essential criteria for its transport, handling, use and

maintenance.

Read this manual carefully before using the machine.

Store this manual with care near the machine so that it can be readily available for

future reference.

If the manual is lost or damaged, you can request a copy from your dealer or

directly from the manufacturer.

If the machine is transferred to a new owner, the latter’s identification and contact

details must be notified to the manufacturer.

The manual reflects the state of knowledge at the time of sale of the machine, and

cannot be considered inadequate in the light of more recent experience and

updates.

The manufacturer reserves the right to update the products and manuals without

being obliged to update previous products and manuals, except in exceptional

circumstances.

In case of doubt, contact your local service centre or the manufacturer.

The manufacturer is committed to continuously improving its products.

For this reason, the manufacturer welcomes any reports or proposals geared

towards improving the machine and/or the manual. The machine is delivered to the

customer with the warranty conditions applicable at the time of sale.

Please contact your dealer for any further information.

1.3 - Warranty

The user is not authorised to tamper with the machine in any way. Contact the

5

manufacturer if you encounter any anomalies.

Any attempt to dismantle, modify or tamper with any part of the machine by the

user or unauthorised personnel will immediately void the Declaration of

Conformity drawn up pursuant to Directive UL 763-CSA 22.2 and the warranty,

and relieves the manufacturer of any liability for damages deriving from such

action.

The manufacturer is also relieved of all liability for the consequences of:

- incorrect installation;

- improper use of the machine by inadequately trained personnel;

- use of the machine in breach of local regulations;

- lack of or negligent maintenance;

- use of non-original spare parts, not specified for the model in question;

- total or partial failure to follow the instructions.

1.4 - Machine description

The pasta machine you have purchased is a straightforward, compact machine

guaranteeing powerful operation and high performance.

- Since it must be used to produce food products, all components that can come

into contact with such products have been carefully chosen to guarantee the

utmost hygiene.

- The bowl is made of 6060 anodised aluminium alloy and grade AISI 304

stainless steel.

- The accessory tool (blade) is made of grade AISI 304 stainless steel.

- The mouth and the screw are made of AISI 304 stainless steel and ø75 dies of

bronze.

- Two operating modes: kneading and extruding mode.

- Maximum dough capacity of 4.2 kg (3 kg of flour + 1.2 kg of eggs).

- Possibility of adding the pasta cutter accessory.

- Single-phase ventilated motors offering the following advantages:

- extremely constant performance and motor duration;

- longer actual work time thanks to fewer interruptions.

The models appearing in this manual are manufactured in conformity to Directive

UL 763-CSA 22.2 and subsequent amendments.

If any accident occurs, the manufacturer shall not be held liable if the machine was

modified, tampered with, with its safety guards removed or used for purposes other

than the intended use specified by the manufacturer.

1.5 - Intended use

The machine is designed to produce fresh-made pasta.

It must be used in a professional setting by qualified operators who have read and

understood this manual. Use the machine exclusively when it is securely placed on

a solid worktable.

After every work cycle, we recommend leaving the machine to rest for a few

minutes before using it again.

1.6 - Improper use

The machine must only be used for its intended purposes; in particular:

6

- Do not use the machine for food products other than pasta and similar.

- Do not use the machine unless it has been properly installed with all its guards

in good working order and correctly fitted, to prevent the risk of serious injury.

- Do not access any of the electrical components without having first

disconnected the machine from the mains power supply: risk of electric shock.

- Follow the proportions of flour and liquid indicated in the use and maintenance

manual. An incorrect flour/egg ratio may also damage the machine

permanently.

- Do not wear clothing that fails to comply with the accident-prevention

regulations. Consult your employer for information on the applicable safety

regulations and personal protective equipment to be worn.

- Do not start the machine if it has a fault.

- Before using the machine, make sure that any potentially hazardous conditions

have been adequately eliminated. If you notice anything unusual in its

operation, shut down the machine and inform the maintenance supervisors.

- Do not allow unauthorised personnel to intervene on the machine.

In case of injury caused by electric shock, the first thing to do is to detach the

injured person from live conductors (as the person will probably be

unconscious).

This operation is highly dangerous.

The injured person in this situation is a conductor: touching him/her would give

you an electric shock.

It would be better to disconnect the mains power supply, or if this is not

possible, move the injured person away using non-conductive materials (a rod

made of wood or PVC, fabric, leather, etc.). First-aid medical assistance should

be requested promptly and the injured person should be taken to hospital.

7

1.7 - Specific equipment details

Citing the "Model", "Serial number" and "year of manufacture" of the machine

will help our technical assistance service to respond to your requests rapidly and

effectively.

We recommend citing the model of the machine and its serial number whenever

you contact the technical assistance service.

This information appears on the rating plate shown in Fig. 1.7.1.

As a reminder, we suggest writing the data of the machine you have purchased in

the table below:

WARNING!

Do not alter the data on the rating plate for any reason.

Pasta Machine model……………….

Serial no. ……………………………..

Year of manufacture…………………

Type…………………………………...

A = Model

B = Power supply

C = Motor power

D = Motor frequency Hz

E = Weight

F = Amperage

G = Year of manufacture

H = Serial no.

I = Manufacturer

L = Barcode

A

B C

D E

F G

H

I

L

Fig. 1.7.1

8

1.7.1 - Warning and danger signs (Fig. 1.7.2)

WARNING!

Do not intervene on the electrical components when the machine is connected to

the mains power supply. You risk getting an electric shock.

Observe the warnings signalled by the signs. Failure to do so could lead to

personal injury.

Make sure that the signs are always present and legible.

If they are not, apply or replace them.

A

Fig. 1.7.2

A

9

1.8 - Guards and safety devices

WARNING!

Before using the machine, make sure that its safety devices are properly

positioned and in good working order.

Check that they are present and work properly at the start of each shift. If not,

notify the maintenance supervisor.

1– Lid presence sensor.

Do not turn on the machine if the lid is open.

WARNING!

Do not tamper with the safety devices for any reason.

1.9 - Work position

To optimise work with the machine, the operator should assume the position

shown in Fig. 1.9.1.

Fig. 1.9.1

1

Fig. 1.8.1

10

2 - Technical specifications

2.1 - Main parts

To aid comprehension of the manual, the main components of the machine are

listed below and shown in Fig. 2.1.1.

1. Feet

2. The kneading tank is made of 6060

anodised aluminium alloy and grade

AISI 304 stainless steel

3. POM-C natural extrusion die

4. ABS NSF 51 distribution funnel

5. Controls

6. Blade unlocking lever

7. Casing

8. AISI 304 stainless steel interlocked lid

9. Die-cast AISI 304 stainless steel

mouth and screw

10. AISI 304 stainless steel accessory tool

(blade)

11. Thermal cut-out

2.2 - Technical specifications

Motor Power source Output / h. Standard dies

watt/hp V/Hz kg/h. ø mm

750/1 110/60 8,4 75

Fig. 2.2.2

10

Fig. 2.2.3

11

Fig. 2.1.1

3

4

8

6

1

5

2

7

9

11

2.3 - Machine dimensions and weight

A B C D E F G Net weight

mm mm mm mm mm mm mm kg

223 414 336 613 557 683 160 42

I

mm

461

L

mm

80

Fig. 2.3.1

12

2.4 - Wiring diagrams

2.4.1 - Single-phase wiring diagram

13

3 - Controls and indicators

3.1 - List of controls and indicators

1 - Switch positioned to kneading mode (FWD)

This position sets the machine to kneading mode; the screw rotates clockwise and

conveys the product to the bottom of the bowl.

2 - Switch positioned to extruding mode (REV)

This position sets the machine to extruding mode; the screw rotates anticlockwise

and conveys the product towards the extruder.

The screw applies pressure to the dough towards the extruder and the pasta starts

drawing.

3 - Switch positioned to motor switch off mode (OFF)

In this position, the motor switches off and the machine stops.

WARNING: The electricity line is still active.

N.B: To switch from kneading mode to extruding mode, switch the machine off,

change the mode selection and turn the machine back on.

4 - “ON” button

This button must be pressed only after having set

the selector switch to extruding or kneading mode.

If the switch is set to OFF the machine will not start.

5 - Stop button

Stop the machine completely by removing the power supply.

WARNING!

the machine is equipped with a forced ventilation system (fan) controlled by a

bimetallic switch connected to the motor. When the motor reaches 60 C, the fan

starts autonomously and continues operating until the motor temperature drops

down to 40°C.

Fig. 3.1.1

1

4 5

2

3

14

4 - Factory testing, shipping, delivery and installation

4.1 - Factory testing

The machine you have purchased has been tested at our plants to verify its correct

operation and proper adjustment. The tests were conducted using materials similar

to those processed by the user.

4.2 - Delivery and handling

All shipped material is carefully checked prior to being handed over to the shipping

agent. Unless otherwise agreed with the customer, the machine is wrapped in

nylon and strapped to the pallet. It is then covered with cardboard, which is also

strapped to the pallet. When you receive the machine, check the condition of its

packaging. If you notice any damage to the packaging, sign the delivery note with

the following wording: “Goods accepted with reservation...” and the reason.

If you notice any damage to the components of the machine after opening the

package, report it to the shipping agent within three days from the date shown on

the documents.

4.3 - Installation

WARNING!

The installation zone must be level and solid, while the surface on which the

machine rests must provide stable and safe support. Moreover, the machine must

be placed where there is ample space around it. This will ensure greater

manoeuvrability during work phases and easy access for subsequent maintenance

operations. Provide adequate lighting around the machine to ensure good visibility

for the operator using it.

- Remove the cellophane wrapping and any other packaging.

4.3.1 - Disposal of packaging

The packaging materials (cardboard, nylon, wood, etc.) can be regarded as solid

urban waste. As a result, they can be disposed of freely. Nylon is a polluting

substance that releases toxic fumes when burnt. Do not burn or dump it, but

dispose of it according to the law. If the machine is delivered to a country where

special regulations apply, dispose of the packaging accordingly.

4.3.2 - Handling the machine

WARNING!

Take care when handling the machine: dropping it accidentally can seriously

damage it. To avoid muscle injuries, lift the machine by flexing your legs.

4.4 - Electrical connections

WARNING!

Check that the power supply line has the same specifications as those shown on

the rating plate of the machine. All interventions must be carried out solely by

specialised personnel expressly authorised by the relevant supervisor. Make the

15

connection to a power line equipped with an efficient earthing socket.

4.4.1 - 110 V-60 Hz single-phase machine

In this configuration, the machine is supplied with a power cable with 3 x 16 AWG

gauge. This cable is connected to a single-phase plug with three pins. Attach the

cable to the 110 V-60 Hz single-phase power supply line by installing a 15 A

residual current circuit breaker in between.

Consult the manufacturer for configurations differing from those mentioned above.

If the power cable needs to be extended, use a cable of the same gauge as the

original cable installed by the manufacturer.

5 - Start-up and shutdown

5.1 - Verification of the correct electrical

connection

Plug the cable into the power socket;

Press the run button (“1”, Fig. 3.1.1).

The direction of rotation of the worm must be anticlockwise in extruding

mode.

If it turns in the opposite direction, disconnect the machine from the power supply

and contact our nearest dealer.

Note:

In machines connected to a single-phase line and specifically designed for this

system, the rotation direction will be defined directly by the manufacturer.

5.2 - Verification of the presence and efficiency of guards and safety devices

1 - Top lid.

Check that when you open the top lid the machine stops.

The machine must NOT work when the lid is open.

5.3 - Verification of the efficiency of the emergency stop button (Fig. 3.1.1)

With the machine connected to the electricity and the accessory tool moving, press

the stop button (5). The machine must stop.

5.4 - Machine start-up (Fig. 3.1.1)

To start the machine, press the button (4) after having set the selector switch to

extruding mode (1) or kneading mode (3) Fig. 3.1.1, and after having correctly

plugged the cable into the power socket: the machine will start. If the switch is set

to OFF the machine will not start.

5.5 - Machine stop (Fig. 3.1.1)

To stop the machine, press the stop button “5” Fig. 3.1.1.

16

6 - Using the machine

6.1 - Safety instructions

WARNING!

Only authorised personnel may intervene on the machine.

Before using the machine, the operator must ensure that all guards are in place

and that the safety devices are present and working efficiently.

If this is not the case, switch the machine off and contact the maintenance

supervisor.

Always make sure that the flour and egg ratio is always 1 kg of flour to 400 g of

eggs.

Prepare the machine by fitting the desired pasta extruder, screw and blade before

starting.

6.2 - Dough preparation

1. Add the flour mix into the mixing bowl

2. Close the top lid and fit the distribution funnel on the lid

3. Start the machine in kneading mode by positioning the selector switch to

position “1” FWD (Fig. 3.1.1)

4. Start pouring the beaten egg into the distributor funnel VERY SLOWLY.

5. After you have finished pouring the egg, wait for the dough to be ready (approx.

15 minutes)

6. Turn the machine off

6.3 - Extrusion

N.B: To switch from kneading mode to extruding mode, switch the machine off,

change the mode selection and turn the machine back on.

1. Check that the desired pasta extruder is positioned inside the ring nut.

2. Start the machine in extruding mode by positioning the selector switch to

position “2” REV (Fig. 3.1.1).

3. The screw feeder will apply pressure to the pasta. As soon as the pasta reaches

the right pressure, it will start being drawn.

4. Take the pasta leaving the die and cut it with a knife to the desired length.

5. Switch the machine off after emptying the tank.

17

7 - Maintenance

7.1 - Safety instructions

WARNING!

Maintenance and cleaning must always be carried out with the machine at a

standstill and disconnected from the mains power supply.

Always keep the maintenance zone clean and dry.

Do not allow unauthorised persons to intervene on the machine.

Any replacements of parts and accessory tools must be performed using original

spare parts at authorised service centres, or directly by the manufacturer.

7.2 - Lubrication

The machine does not require any lubrication.

7.3 - Cleaning the machine

WARNING! Disconnect the machine from the mains power supply before cleaning

it. Do not clean the machine using a water jet. Only use non-toxic detergents

specifically formulated for cleaning components used with foodstuffs.

7.3.1 - Removing the accessory tools

At the end of each processing cycle,

remove the accessory tools to clean

the machine effectively

Removing the mixer blade

1. Put the blade “1” in the position

shown in Fig. 7.2.1.

2. Raise the lever “2” and remove the

bar “3”.

3. Remove the blade “1” by sliding it

upwards.

WARNING! If the blade is not lying in

the position shown in Fig. 7.2.1, it

cannot be removed.

Removing the worm

1 - unscrew the ring nut 4

2 - remove the die 5

3 - remove the worm 6

WARNING!

Make sure that you clean the drive pins thoroughly after

use

in order to ensure correct coupling

of the blade and screw (Fig. 7.2.2)

1

Fig. 7.2.1

2

3

5

4

6

Fig. 7.2.2

18

7.3.2 - Removing the bowl

To clean the machine thoroughly at the end of each processing cycle, you can also

remove the bowl.

Follow these operations to correctly remove the bowl:

REMOVING THE BLADE

- remove the liquid dosing tank REF. 1, lift the

lid up REF. 2, rotate the lever anticlockwise

REF. 3. By holding with one hand the blade

REF. 5, remove the bar REF. 4.

Then lift-up and remove the blade REF 5.

REMOVING THE SCREW

- unscrew the ring nut REF. 7 by rotating it

clockwise using the key REF. 6 and remove

the die REF. 8 and remove the screw REF. 9.

REMOVING THE COUPLING

To remove the coupling REF. 11, undo the 4 bolts

REF. 10 which fasten it to the bowl, and remove it.

REMOVING THE LID

To remove the lid REF. 2, hold it with one hand,

unscrew the knob REF. 12 and remove it.

REMOVING THE BOWL FRONT PANEL

To remove the front panel REF. 14, hold it still with

one hand and unscrew the 8 remaining knobs

REF. 13; the front panel is now loose and can be

removed.

REMOVING THE BOWL

After correctly completing all the above operations,

pull the bowl towards you with two hands REF. 15.

15

12

2

13

14

10

11

1

2

3

4

5

6

7

8

9

Fig. 7.3.4

Fig. 7.3.1

Fig. 7.3.3

Fig. 7.3.2

19

7.3.3 - Reassembling the bowl

Follow these operations to reassemble the bowl correctly:

REASSEMBLING THE BOWL

After having centred the bowl correctly REF. 15

with the 9 pins REF. 16, use two hands to push it

into position until it is fully in contact with the

casing.

REASSEMBLING THE BOWL FRONT PANEL

To reassemble the front panel REF. 14 after

having centred it correctly with the 9 pins REF. 16,

hold it still with one hand and push it towards the

bowl until it stops REF. 15; then fasten it by

tightening the 8 knobs REF. 13.

REASSEMBLING THE LID

To reassemble the lid REF. 2, insert the knob

REF. 12 in the 2 holes on the side flaps of the lid.

Position the lid on axis with the threaded hole

REF. A on the casing. Tighten the knob REF. 12

until the lid is completely fastened.

REASSEMBLING THE COUPLING

To reassemble the coupling REF. 11, align it to

the 4 M8 bars REF. 17, then push it until it stops

against the front panel REF. 14 and fasten the

whole by tightening the 4 bolts REF. 10 while

holding the coupling with one hand and making

sure that the parts are correctly aligned.

15

16

12

2

13

14

A

10

11

17

14

Fig. 7.3.6

Fig. 7.3.5

Fig. 7.3.7

20

REASSEMBLING THE SCREW

- Insert the screw REF.9 inside the

coupling REF. 11, by pushing completely

inside and making sure that the rear part

of the screw is correctly coupled with the

drive pin inside the bowl. Insert the die

REF.8 in the pin on the screw and tighten

the ring nut REF. 7 by rotating it

clockwise.

REASSEMBLING THE BLADE

- insert the blade inside the bowl by positioning it aligned with the flange REF. 18

located on the front panel of the bowl. By holding the blade into position with one

hand, insert the bar REF. 4 inside the flange and through the blade until it stops.

Rotate the lever clockwise REF. 3 to its horizontal position.

N.B: Make sure that the lever is correctly fixed in its position on the bar REF.4. If

not, push or pull towards you the bar until it is correctly aligned in order to fasten

the lever REF. 3. Then close the lid so that it rests on the bowl and make sure that

the magnet on its edge is positioned in axis with its sensor REF. B which is located

on the machine. Reassemble the liquid dosing tank REF. 1.

1

2

3

4

5

11

7

8

9

18

B

Fig. 7.3.8

Table of contents

Other Univex Pasta Maker manuals