3

Safety Precautions

FOR SAFE INSTALLATION AND OPERATION OF YOUR

“Urbana” Appliance, PLEASE CAREFULLY READ THE FOLLOWING

INFORMATION:

• All Urbana gas-red appliances must be installed

in accordance with their instructions. Carefully read

all the instructions in this manual rst. Consult the

building authority having jurisdiction to determine the

need for a permit prior to commencing the installation.

• Failure to follow these instructions may also void

your re insurance and/or warranty.

• Installation and repair should be done by

a qualied service person. The appliance

should be inspected before the rst use

and, at least, annually by a qualied service

person. More frequent cleaning may be

required as necessary. It is imperative

the control compartments, burners and

circulating air passageways of the appliance

be kept clean.

• Children and adults should be alerted to

the hazards of high surface temperatures

and should stay away to avoid burn or

clothing ignition. Young children should be

carefully supervised when in the area of the

appliance.

• Any guard, barrier, or other protective device

removed for servicing the appliance shall be

replaced prior to operating the appliance.

• Clothing or other ammable materials

should not be hung from the appliance or

placed on or near the appliance.

• This appliance must not be operated in

temperatures below freezing (0C / 32F). Allow

the temperature of the appliance to warm up

above freezing prior to operation.

• This appliance is certied for outdoor use only and

must not be used or installed indoors.

FOR YOUR SAFETY

• Always keep the area around these appliances clear

of combustible material, gasoline and other ammable

liquids and vapours.

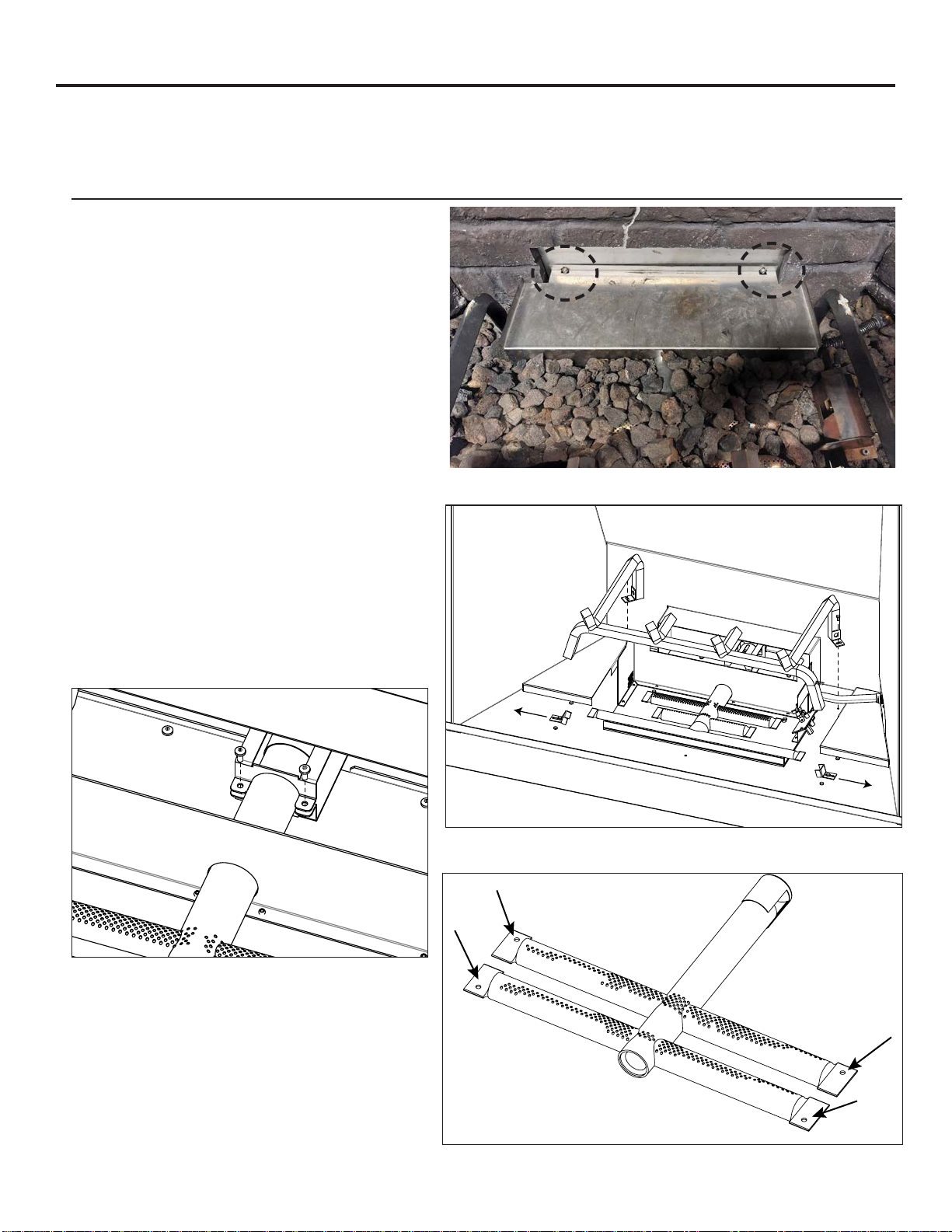

WARNING: Failure to position the parts in accordance

with the diagrams in this booklet, or failure to use only

parts specically approved with this appliance, may

result in property damage or personal injury.

• Never use solid fuels such as wood, paper, cardboard,

coal, or any ammable liquids, etc., in this appliance.

• Do not use this appliance if any part has been under

water. Immediately call a qualied service technician

to inspect the appliance and to replace any part of

the control system or any gas control which has been

under water.

• Toddlers, young children and others may be

susceptible to accidental contact burns. To restrict

access to the appliance install an adjustable safety

gate to keep toddlers, young children and other at risk

individuals away from hot surfaces.

IMPORTANT NOTICE (Regarding rst re

up): When the unit is turned on for the rst time,

it should be turned onto high for the rst 4 hours.

This will cure the paint, logs and other products

used in the manufacturing process. The unit will

start to smoke and can irritate some people.