Instructions Manual – Eline NPE 2 12/21/2011

SAFETY FIRST

High voltage and rotating parts can cause serious or fatal injury. Qualified

personnel must perform safe operation, and maintenance. Familiarization with

and adherence to NEMA MG2, the National Electrical Code (NEC) and local

codes is required. It is important to observe safety precautions to protect

personnel from possible injury. Personnel should be instructed to:

1. Be familiar with the equipment and read all instructions thoroughly before

installing or working on equipment.

2. Avoid contact with energized circuits or rotating parts.

3. Disconnect all power sources before initiating any maintenance or repair.

4. Act with care in accordance with prescribed procedures in handling and

lifting this equipment.

5. Be sure unit is electrically grounded in accordance with code

requirements.

6. Be sure equipment is properly enclosed or protected to prevent access

by children or other unauthorized personnel in order to prevent possible

accidents.

7. Be sure shaft key is fully captive before unit is energized.

8. Avoid contact with capacitors until safe discharge procedures have been

completed.

9. Provide proper guarding for personnel against rotating parts and

applications involving high inertia loads, which can cause overspeed.

10. Avoid extended exposure to equipment with high noise levels.

INSPECTION AND HANDLING

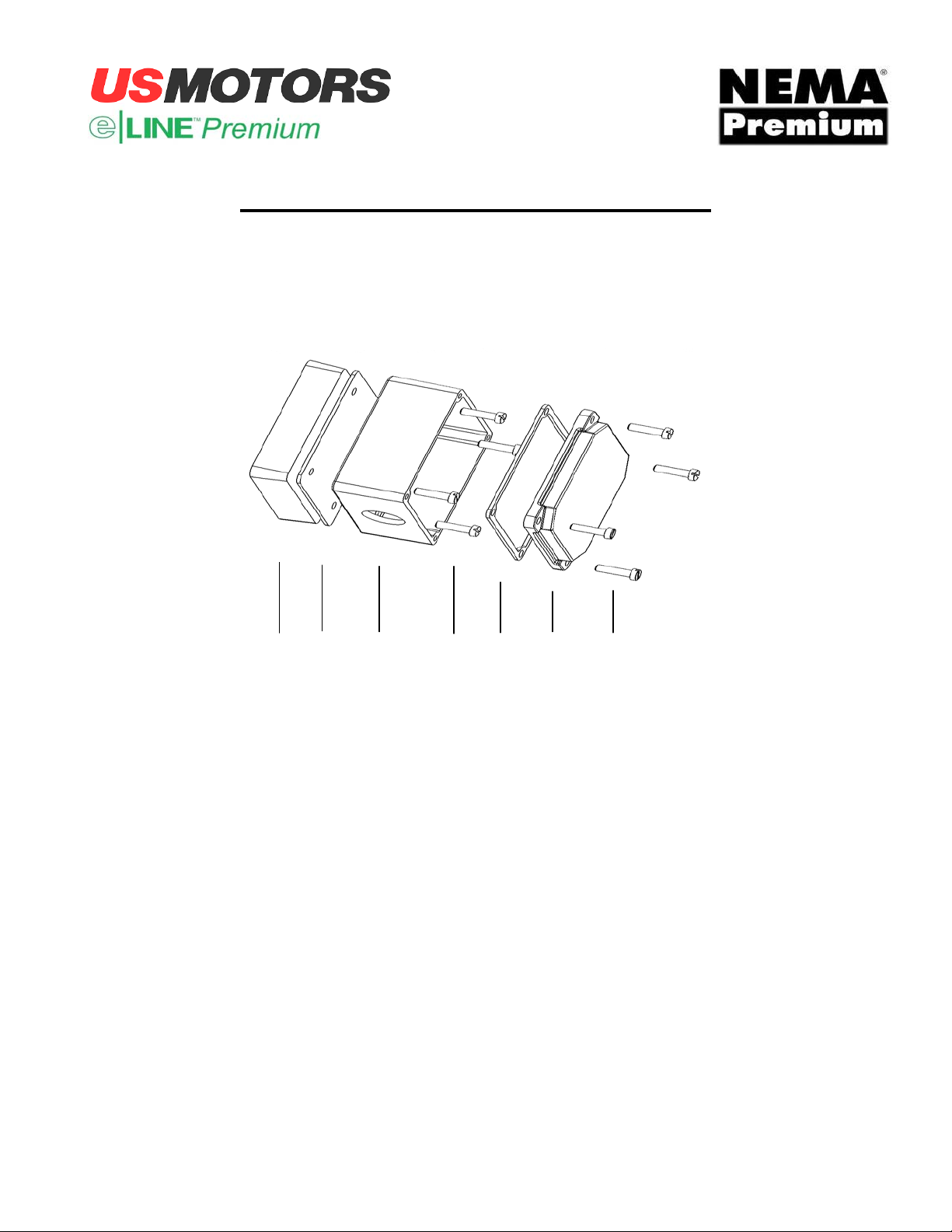

Inspect unit to make sure no damage has occurred during shipment.

Check nameplate for correct speed, horsepower, voltage, Hertz, and phase for

conformance with power supply and equipment. WARNING: Units should be

lifted using all eyebolts or lugs if provided. These eyebolts or lugs are provided

for lifting this unit only and must not be used to lift any additional weight. Lifting

angle, from shank of eyebolt, must not exceed 30° for machines with single and

45° for machines with multiple lifting means. Replacement eyebolts must be per

ASTM A489 or equivalent. All eyebolts must be securely tightened. Be careful

not to touch overhead power lines with lifting equipment. Failure to observe this

warning may result in serious personal injury.