V-King MK2 User manual

V-King MK2

The V-King MK2 was released in May 2020. All parts changed from MK1 are colored yellow in the Fusion 360 model .

The changes done in MK2 are:

● Simplified worm gear and rod brackets, easier to assemble

● All X, Y, and Z Idler buddies adjusted to accommodate better (larger) idlers from Gates/Mellow ( Video and Stream )

● Improved and adjusted X carrier

1. Introduction

a. printing the parts (choosing filament, settings)

b. how to get help (Discord, FB group)

c. required hardware (with images)

d. Required tools

e. How to look at the drawings in Fusion 360

2. Sourcing Guide

3. Base Frame Assembly

a. Corner part of the frame

b. XY motors with brackets

c. XY idler corner pulleys

4. X-Axis Assembly

a. XY Forks

b. X Idlers

c. X Carrier

d. X Carrier - cable loom bracket

e. X Carrier - hotend and fans

f. Y Carriers

g. X-axis assembly

5. Mounting and tensioning the X/Y belts

a. How to add belts

b. Tensioning

6. Z Drive Assembly

a. Z carriers

b. Bed frame, bed support

c. Bed idlers

d. Belt anchors (top)

e. Worm gear, rod, rod buddy

f. Add the Z belts

7. Extruder

a. Bowden tube

b. Cable loom

8. Electronics

a. Mount the components

b. Wiring, cable management

9. Firmware

10. Panels

a. Bottom panels

11. Get started printing

a. Tune extruder

b. Bed leveling

V-King MK2 Assembly Manual 2021-02-27 2 / 41

https://vkingprinter.com/

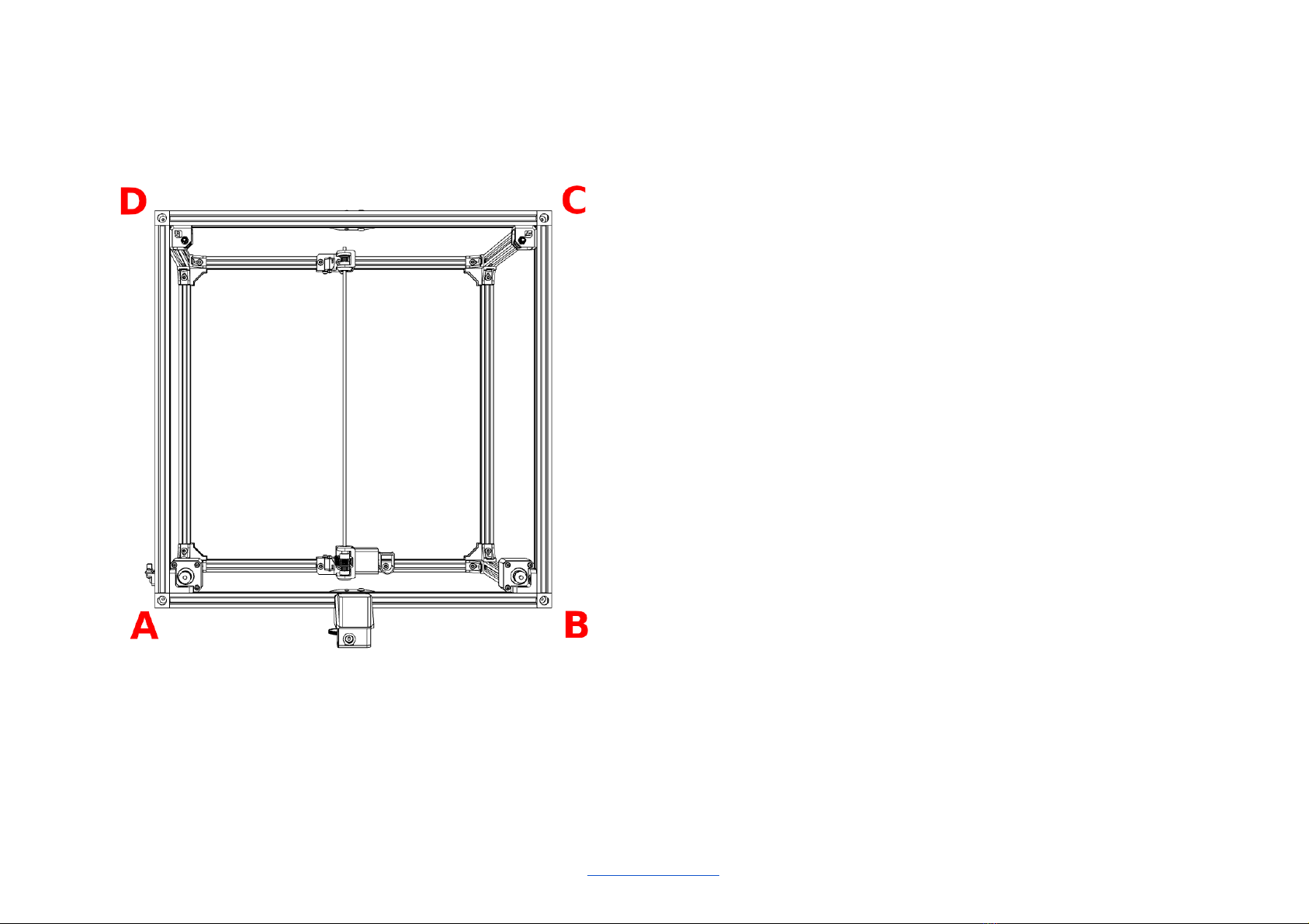

Naming of the corners

Overview of additional placed T-nuts

Lower V slots

A-B facing out: 3 for the gear buddy and tensioner

A-B facing up: 2 for the gear buddy

A-B facing in: 3 for gear buddy and tensioner

D-C facing out: 3 for the gear buddy and tensioner

D-C facing up: 2 for the gear buddy

D-C facing in: 3 for gear buddy and tensioner

Upper V slots

A-B facing up: 4 for extruder and cable conduit,

A-B facing down: 2 for Z belt

D-C facing out: 4 for belt tensioners

D-C facing down: 2 for Z belt

V-King MK2 Assembly Manual 2021-02-27 4 / 41

https://vkingprinter.com/

Corner part of the frame

Hardware parts

12 500 mm V-slot Rails with M5 threaded/tapped ends

8 Corner Cubes

24 M5 x 8mm Countersunk Bolts

20 Cast Corner Brackets, large 20mm x 28mm x 28mm

40 M5 x 10 mm Button Head Screws

40 M5 Washers

68 M5 Tee Nuts

Printed parts

none

Videos

Fusion 360 animation - Base Frame Assembly

Live Build - Main Frame - The Corners

Step by step

1. Make sure you’re building on a completely flat surface.

2. Start with loosely fastening the corner brackets with the button head screws

and washers.

3. Add the right amount of tee nuts before mounting the corner cubes, see

separate overview.

4. Add the corner cubes using the countersunk screws. Tighten the corner cubes

first - do not use too much force when tightening.

5. Tighten the corner bracket screws carefully.

6. In real life it is almost impossible to square the frame TRUE 90 degrees in 3

dimensions. Do your best. What is important is that the Y-axis is parallel to each

other, and that the X-axis is adjusted 90 degrees to the Y axis.

V-King MK2 Assembly Manual 2021-02-27 5 / 41

https://vkingprinter.com/

XY motor corner brackets

The XY motors are located in corners A and B.

Hardware parts

4 M5 x 10 mm Button Head Screws

4 M5 Washers

6 M3 x 8 mm Button Head Screws

6 M3 Washers

2 Nema 17 Stepper Motors 17HS4401S

2 GT2 Motor Pulleys with 20 Teeth

Printed parts

2 XY Motor Corner Bracket_2x_SN_BN_100%.stl

Videos

Fusion 360 animation - XY Gantry Assembly

Live build (MK1) - Motor pulleys

Step by step

1. Mount the brackets with the M5 screws and washers

2. Mount the motors with the M3 screws and washers.

3. The A motor pulley mounts with the teeth up. The top of the

pulley should be 23 mm from the top of the motor housing.

4.

V-King MK2 Assembly Manual 2021-02-27 6 / 41

https://vkingprinter.com/

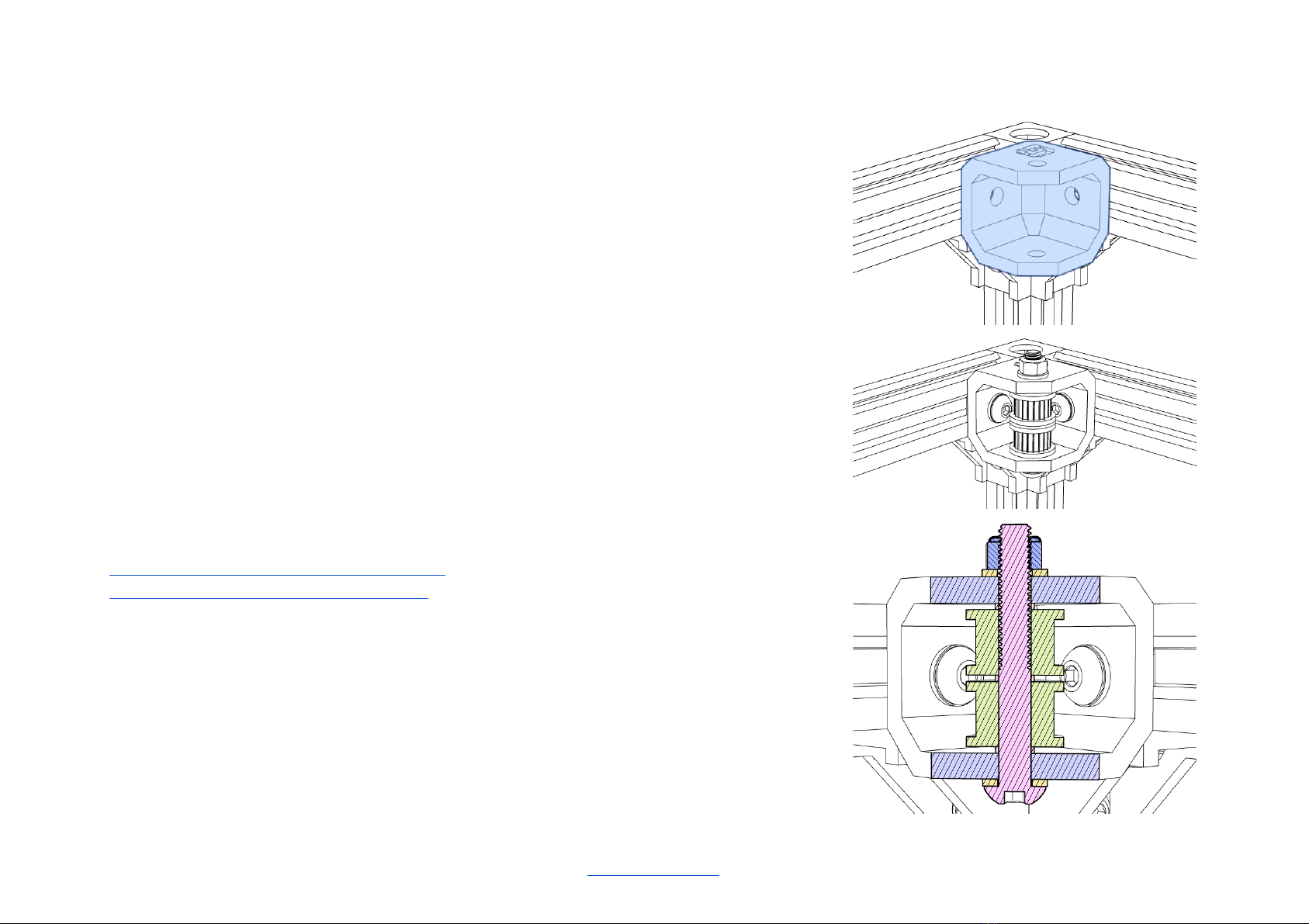

XY corner idlers

The XY corner idlers are located in the corners C and D.

Hardware parts

4 M5 x 10 mm Button Head Screws

8 M5 Washers

2 M5 x 35 mm Button Head Screws

2 M5 x Lock nuts

4 M5 washers

6 M5 precision shims, 5 mm ID x 6 mm OD x 1 mm

4 GT2 Idlers with 20 teeth

Lithium based lubricating grease

Printed parts

2 XY Corner Idler Buddy_2x_SN_BN_100%.stl

Videos

Fusion 360 animation - XY Gantry Assembly

Live build - Corner Idler Bracket Assembly

Step by step

1. Mount the brackets with the specified screws and washers

2. Lube up the pulleys with the lithium grease before mounting.

3. Mount the washers on the outside, and the shims on each side of the

pulleys. If the opening in the buddy is tight, the upper shim can be dropped.

4. Attach the lock nut on top. The lock nut should not be pressing against the

buddy. Leave a small gap between them.

V-King MK2 Assembly Manual 2021-02-27 8 / 41

https://vkingprinter.com/

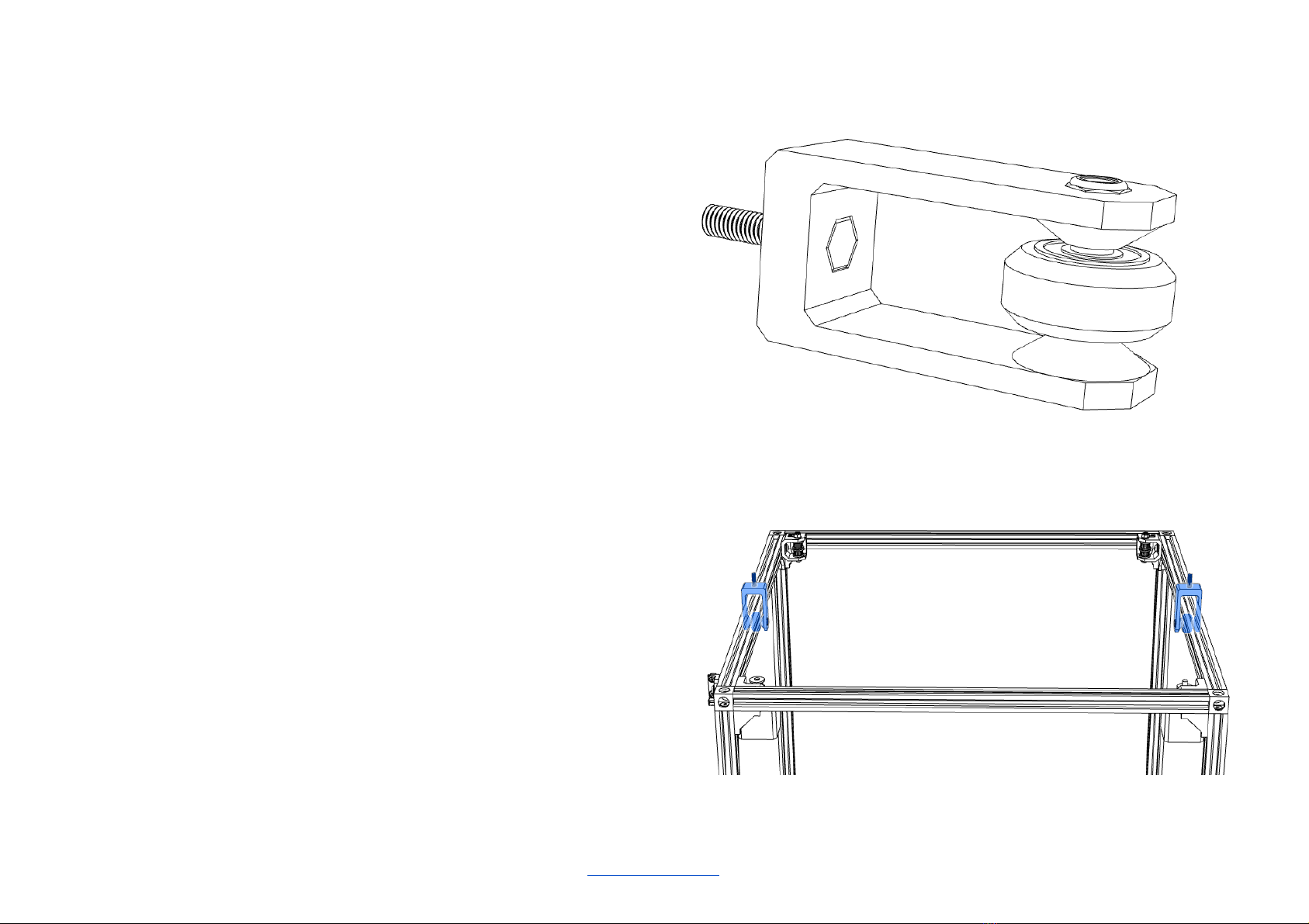

XY Forks

2 Y Carrier forks, 1 X Carrier fork, 4 Z Carrier forks

Hardware parts

Wheels:

3 Solid V Wheels (with included shims)

6 Ball Bearings 625 RS 5x16x5

6 M5 x 6,5 mm x 1 mm Precision Shims

Forks:

3 M5 x 20 mm Hex Bolts

3 M5 x 25 mm Button Head Screws

3 M5 Lock Nuts

3 M5 Nuts

Printed parts

3 XYZ Carrier Fork_7x_SN_BO.stl

3 XYZ ThumbScrew_7x_SB_BN.stl

Step by step

1. Mount the bearings in the wheels, with the included shim between

the bearings.

2. Insert the hex head screw into the fork. Make sure the head is

properly aligned.

3. Place the two Y carrier forks on top of the A-D and B-C top rails.

4. Mount the wheels in the fork, with one precision shim between the

bearing and the fork on each side Use the M5 x 25 mm Button

Head Screw for the wheel.

5. Assemble the last fork for the X carrier, and set it aside.

V-King MK2 Assembly Manual 2021-02-27 10 / 41

https://vkingprinter.com/

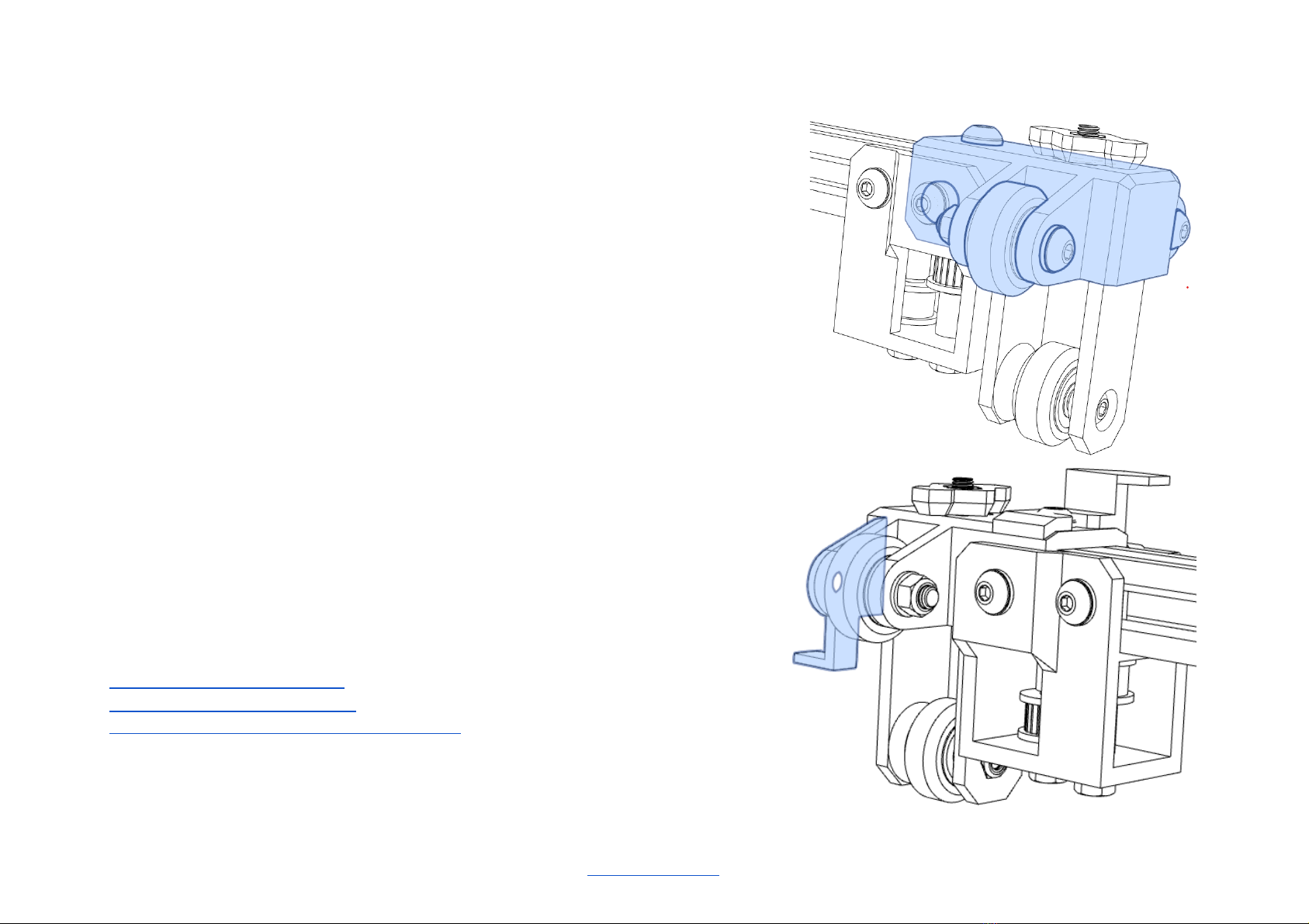

X Idlers

Hardware parts

4 M5 x 35 mm Hex Bolts

4 M5 Nuts (with low-strength threadlocker)

4 M5 Washers

2 GT2 Idlers without teeth

2 GT2 Idlers with 20 teeth

8 M5 Precision Shims, 5 mm ID x 6 mm OD x 1 mm

Printed parts

2 GX Axis Idler Buddy_2x_SA_BN.stl

4 GX Axis Idler Spacer_4x_SN_BY.stl

Videos

Fusion 360 Animation - Adding the X-axis and the X idlers

Live Build - X Idler Bracket Assembly

Step-by-step

1. Be aware that the two idlers are not equal.

2. Mount the hardware parts as shown in the images, there

should be a precision shim on each side of the idler.

3. Fasten the M5 hex bolt loosely, as it has to be tightened after

mounting it on the X-axis.

V-King MK2 Assembly Manual 2021-02-27 11 / 41

https://vkingprinter.com/

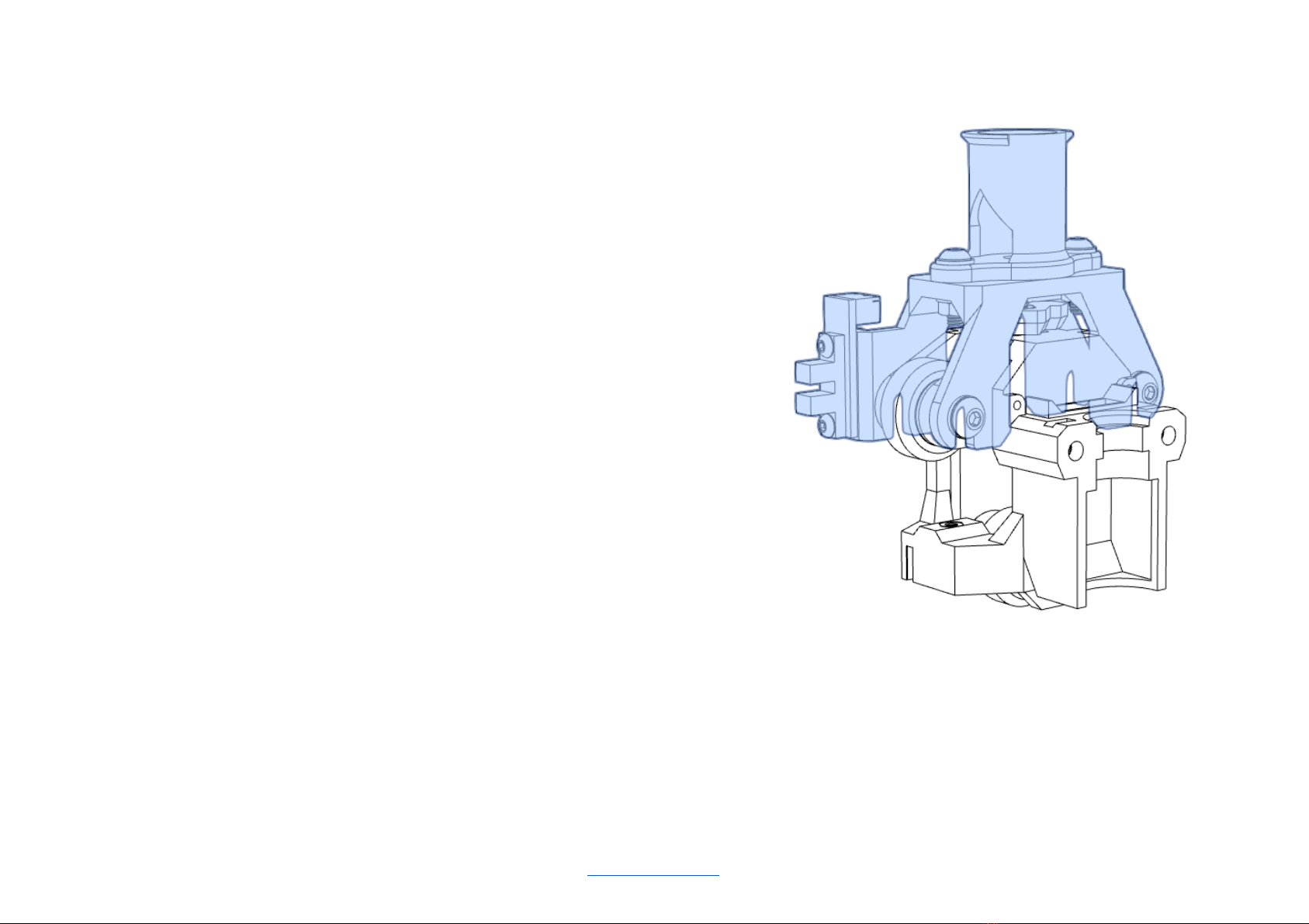

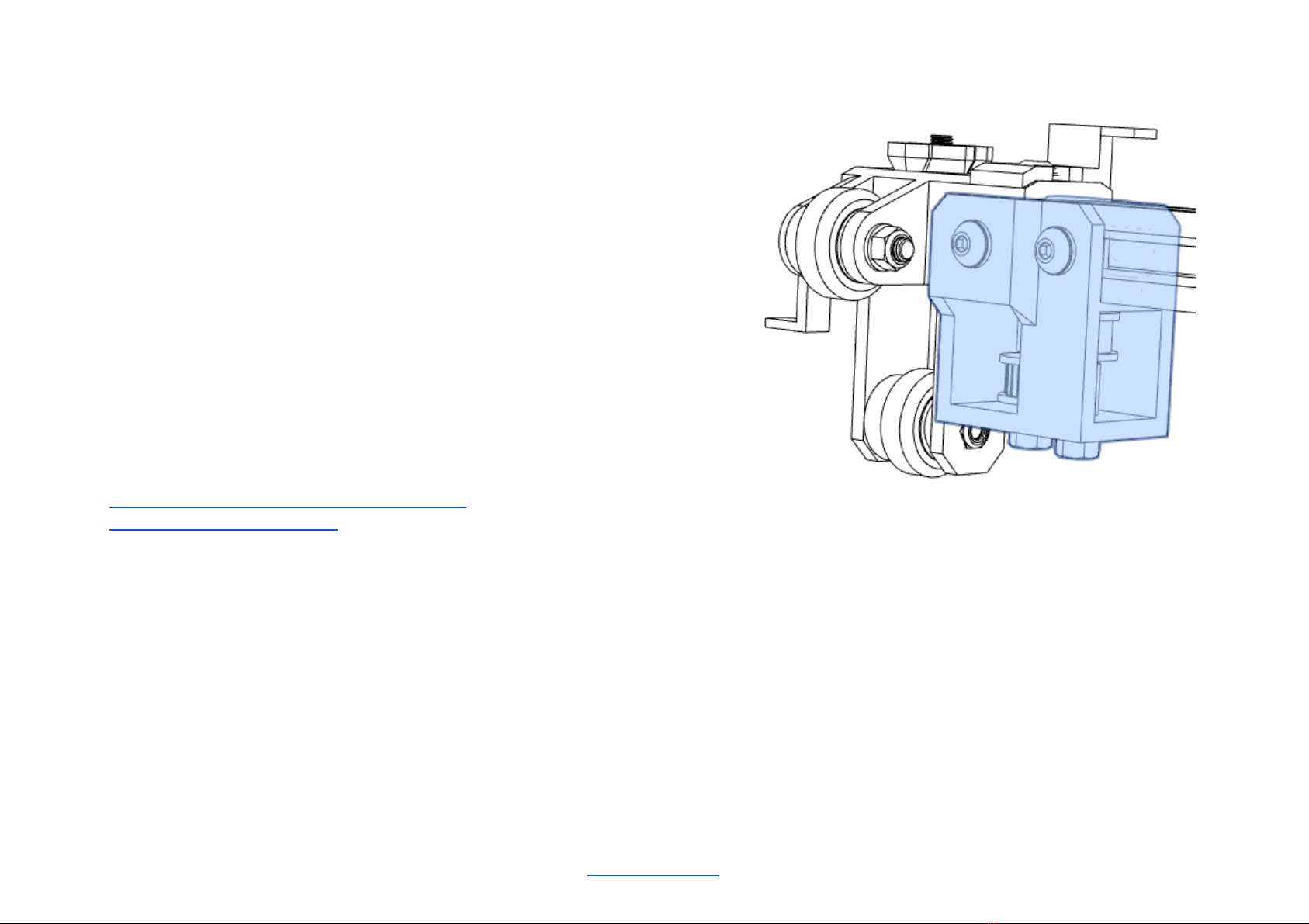

X Carrier

Hardware parts

1 assembled XYZ fork with thumb screw

Wheels:

2 Solid V Wheels (with included shims)

4 Ball Bearings 625 RS 5x16x5

4 M5 x 6,5 mm x 1 mm Precision Shims

2 M5 x 35 Button Head Screws

2 M5 Lock Nuts

4 M5 Washers

2 M3 Nuts

Printed parts

1 X Carrier V2 201_1x_SA_BN.stl

Videos

Fusion 360 Animation - Assemble the X Carrier

Step-by-step

1. Mount the bearings in the wheels, with the included shim between the bearings.

2. Mount the wheels into the X carrier with the M5 bolts, washers, and locknuts.

3. Slide the prebuilt XYZ fork into the X carrier, and fasten it loosely with the

thumbscrew.

4. Add the M3 nuts in the recesses in the X carrier. Be sure to remove all supports

in the holes. TIP: if it is difficult to get the nuts in place, you can heat them up

with the tip of a soldering iron and gently press them into place.

V-King MK2 Assembly Manual 2021-02-27 12 / 41

https://vkingprinter.com/

X Carrier - cable loom bracket

Hardware parts

2 M4 x 16 mm Button Head Bolts

4 M4 Washers

2 M4 Nuts

1 Optical Sensor

2 M3 x 12 mm Button Head Bolts

2 M3 Nuts

Printed parts

1 X Carrier Cable Loom Bracket_1x_SB_BO.stl

1 X Carrier Cable Loom Tube_1x_SN_BN.stl

Videos

None

Step-by-step

1. Fasten the cable loom tube to the bracket with the M4 bolts, washers, and nuts.

2. Fasten the optical sensor to the bracket with the M3 bolts, washers, and nuts.

3. Fasten the bracket loosely to the X carrier.

V-King MK2 Assembly Manual 2021-02-27 13 / 41

https://vkingprinter.com/

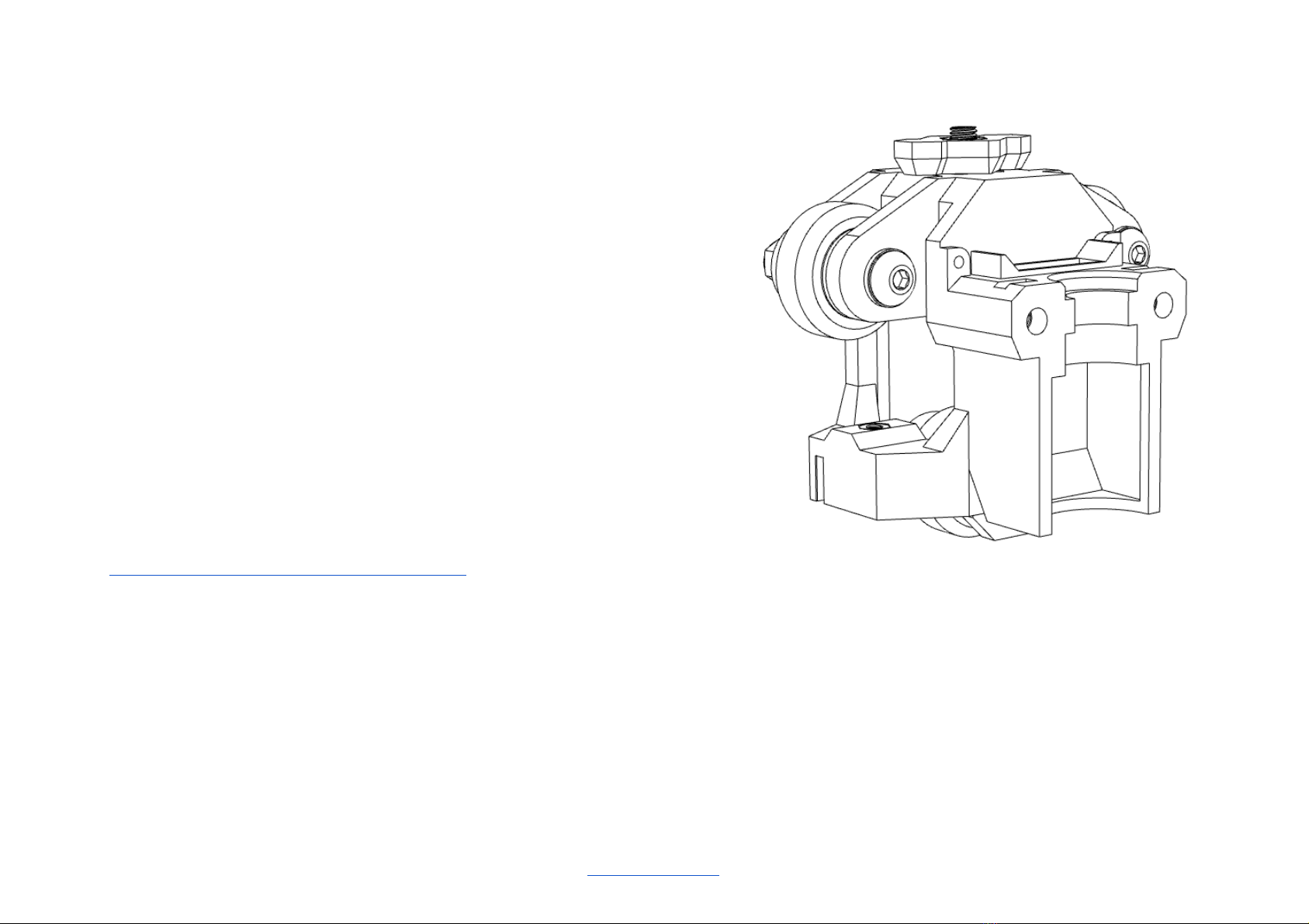

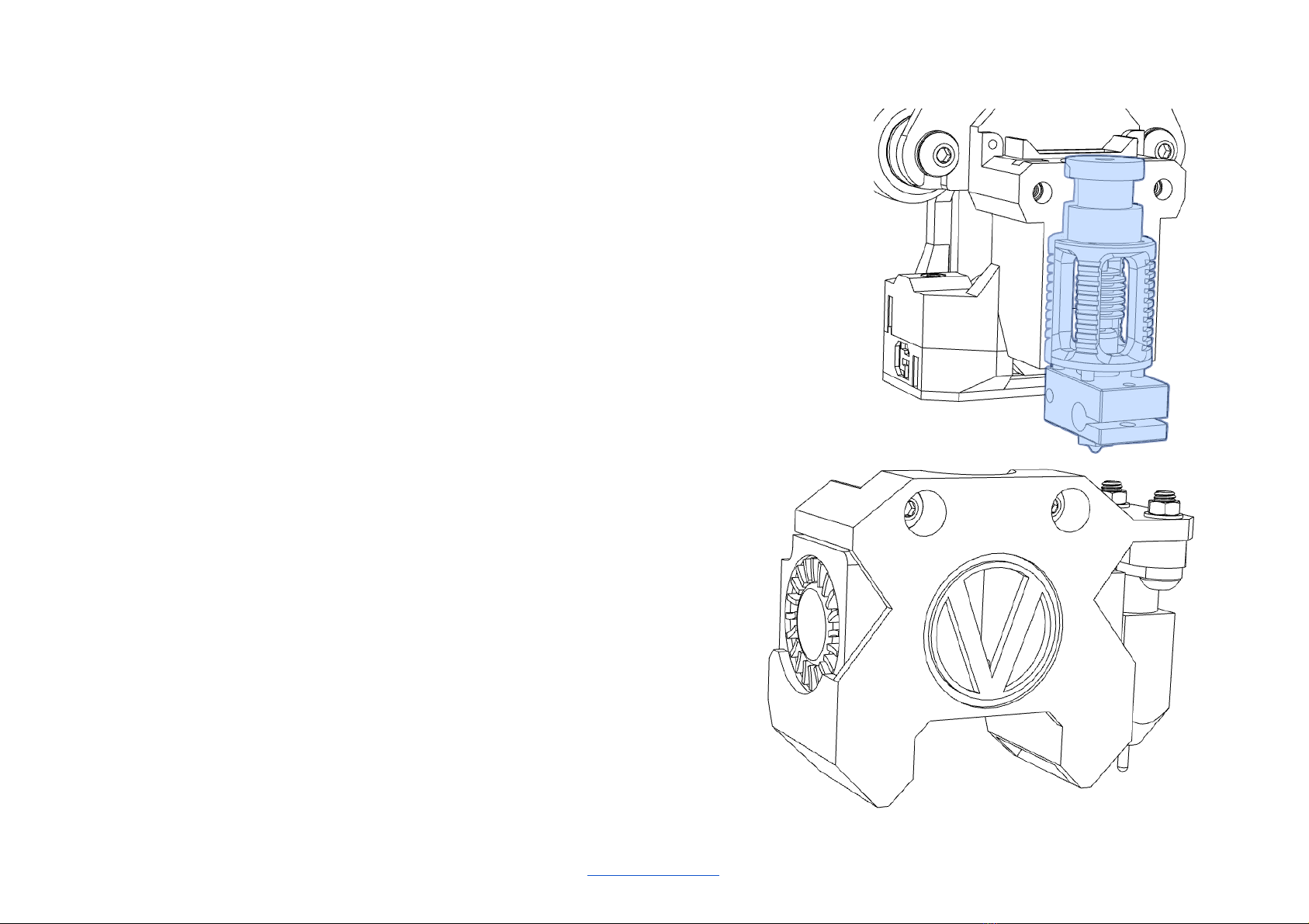

X Carrier - hotend and fans

Hardware parts

1 Dragon Hotend

1 BL Touch Probe with mounting bolts, nuts, and washers

2 3010 Blower Fans, 30x30x10 mm

1 4010 Blower Fan, 40x40x10 mm

2 M4 Nuts

2 M4 x 12 mm Button Head Bolts

2 M2,5 x 12 mm Button Head Bolts

2 M2,5 x 16 mm Button Head Bolts

2 M2 x 6 mm Button Head Bolts

Printed parts

1 X Carrier Hotend Buddy_1x_SA_BN_100%.stl

1 BL Touch Spacer 5mm_1x_SN_BN.stl

1 X Carrier Blower Fan Grill_1x_SN_BN_100%.stl

Videos

None

Step-by-step

1. Insert the 3010 fans into the fan shroud, and fasten with

the M2 x 6 mm bolts

2. Mount the BL Touch with the included bolts, nuts, and

washers. Insert the printed spacer between the Bl touch

and the fan shroud. Note that some have had to print a

higher (8 mm) spacer than the original.

3. Mount the hotend in the X carrier.

V-King MK2 Assembly Manual 2021-02-27 14 / 41

https://vkingprinter.com/

4. Slide 2 M4 nuts into the holes in the X carrier, and

fasten the fan shroud with the 12 mm M4 bolts.

5. Mount the 4010 fan and the printed fan grill on top of the

X carrier, with the M2,5 Bolts. Use the 16 mm bolts to

fasten the fan to the carrier, and the 12 mm bolts on top.

V-King MK2 Assembly Manual 2021-02-27 15 / 41

https://vkingprinter.com/

Y Carriers

Hardware parts

Wheels:

4 Solid V Wheels (with included shims)

8 Ball Bearings 625 RS 5x16x5

8 M5 x 6,5 mm x 1 mm Precision Shims

Y Carriers:

4 M5 x 30 mm Button Head Screws

4 M5 Lock Nuts

8 M5 Washers

Y Endstop bracket:

1 Optical Sensor

2 M3 x 12 mm Button Head Bolts

2 M3 Nuts

Printed parts

2 Y Carrier_2x_SB_BO.stl

1 Y EndStop Flag_1x_SN_BN.stl

1 Y EndStop Bracket_1x_SN_BO.stl

Videos

OpenBuilds V Wheel assembly

Fusion 360 animation - Y Carrier

Live build - Y Carriers and X-axis to the Frame

V-King MK2 Assembly Manual 2021-02-27 16 / 41

https://vkingprinter.com/

Step by step

1. Mount the bearings in the wheels, with the included shim

between the bearings.

2. Remember to mount the endstop flag on the carrier on the

A-D side, while mounting the wheel.

3. Mount the wheels in the Y carrier, with one precision shim on

each side of the wheel. Use the M5 x 30 mm Button Head

Screw for the wheel, with washers and locknuts.

4. Fasten the optical sensor to the endstop bracket with the M3 bolts, washers, and

nuts.

5. Fasten the endstop bracket to the top rail in the base frame near motor A.

V-King MK2 Assembly Manual 2021-02-27 17 / 41

https://vkingprinter.com/

X-Axis Assembly

Hardware parts

1 480 mm V-slot Rails

X idlers:

5 M5 10 mm Bolt Head Screws

5 M5 14 mm Bolt Head Screws

10 M5 Washers

10 M5 Tee Nuts

Low-strength threadlocker ie. Loctite® Purple 222

Printed parts

1 X EndStop Flag_1x_SN_BY.stl

Videos

Fusion 360 Animation - Assemble the X Carrier

Live Build - X Carrier to X-axis

Step-by-step

1. Slide the first X idler buddy on the V-rail. Make sure that the bolt heads are loose, and

fit into the rail. Fasten the X idler buddy loosely with the M5 10 mm screws closest to

the X carrier. Push it 5 cm into the end.

2. Slide the X carrier loosely on the V-rail. Be sure to mount it the right way, with the

thumbscrew lose.

3. Mount the last X idler loosely on the V-rail, the same way as the first one.

4. Insert a tee nut on both sides and at the top of the V-rail. Do this at both ends.

5. Slide the x-axis gently into the Y carriers, with equal distance from the X-carrier rail to

the bottom of the Y carriers.

V-King MK2 Assembly Manual 2021-02-27 18 / 41

https://vkingprinter.com/

6. Attach the Y carriers on top of the forks. Be sure to align the wheels on the Y carriers

to the rails.

7. Insert the nut in the thumbscrew, and tighten with the Y carriers.

8. Align the X-axis perpendicular to the Y-axis before continuing. As long as the corners

are 90 degrees, you can slide the X-axis to the motors - and use them as a reference.

9. Fasten the X-axis to the Y carrier on the B-C side with an M5 10 mm bolt at the top.

10. Fasten the X-axis to the Y carrier and the X end stop flag on the A-D side with an M5

14 mm bolt at the top.

11. Slide the X idlers outside the Y carrier. Use an allen key or similar to ensure that the

holes on the sides align. Ensure that the tee nut is placed properly.

12. Insert the M5 14 mm screws, and tighten carefully.

13. Tighten all screws carefully. Do not use too much force.

14. Apply a little low-strength threadlocker on the hex bolts under the X idler, before

fastening the M5 nut. Do not tighten too much, or you will break the plastic.

V-King MK2 Assembly Manual 2021-02-27 19 / 41

https://vkingprinter.com/

Table of contents