5

The piston pump starts when the pressure drops below a starting value of 5 bar relative pressure. Consequently, if for the

intended process it is required to increase the pressure, which is at the moment higher than the starting pressure value (e.g. the

process requires a relative pressure of 7 bar, and the current pressure in the tank is 6 bar relative pressure), it is necessary to

lower the pressure to a value below 5 bar. This will start the pump, and then increase the pressure to a maximum value of 8 bar.

Pressure can be reduced by opening the compressor outlet valve (positioning the valve handle parallel to the valve).

Remember to close the valve (position the handle perpendicular to the valve). Leaving the outlet valve open may impossible to

overpressure build-up and cause the pump overheating.

1) Make sure the switch is in the "OFF" position before connecting the compressor to the power supply.

2) Close the outlet valve (place the valve handle perpendicular to the valve)

3) Connect the compressor's power cord to the mains supply.

4) Start the compressor by setting the switch to the "ON" position.

5) If the relative pressure in the tank is lower than 5 bar, the piston pump will automatically start, and stop when the pressure

in the tank will increase to 8 bar relative pressure.

6) If the relative pressure in the tank is higher than 5 bar, the pump will not start.

7) The pressure in the tank can be controlled on the tank manometer, which is located below the pressure regulator. When the

compressor is on, and the pump is stopped, the pressure gauge should show a value between 5 and 8 bar relative pressure.

8) Check the pressure at the tank outlet valve. It is indicated on the reducer manometer.

9) If change of pressure on the tank outlet valve is required:

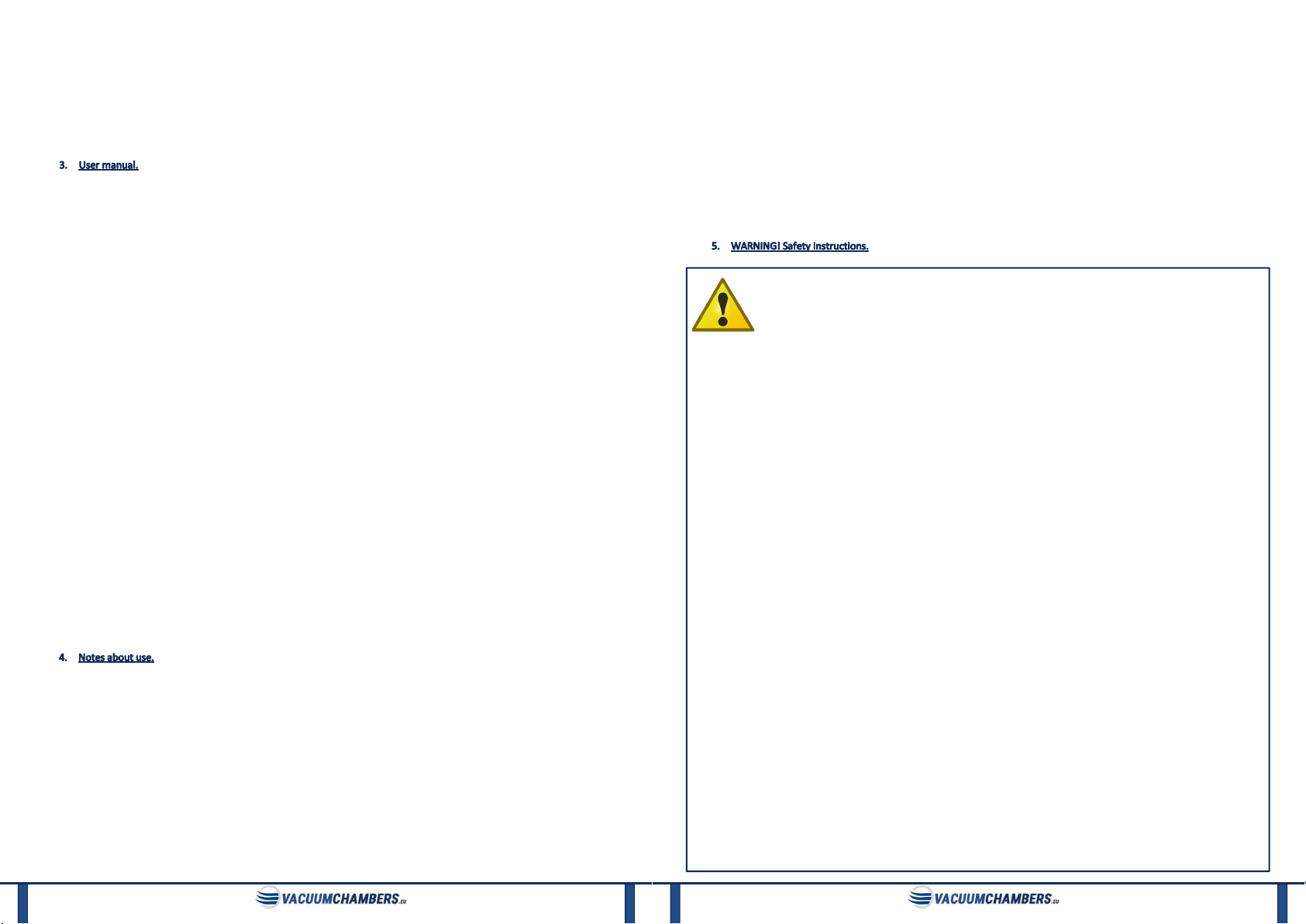

a. Gently lift the blue reducer knob.

b. Set the pressure on the outlet valve by turning the knob clockwise to increase it, or anticlockwise to reduce it. The range

of pressure values that can be achieved on the regulator is limited and is described in section 2. A. „Outlet pressure

regulation.” of this manual.

c. After the intended pressure value has been set, press the reducer knob slightly downwards to lock the settings.

10) Connect with compressor outlet valve the components with which compressor is to cooperate. Follow the operating manual

of those components.

11) Open and close the compressor outlet valve as required by the process.

a. To open the valve and to release the compressed air stream, position the valve handle parallel to the valve.

b. To close the valve and block the compressed air flow, position the outlet valve handle perpendicular to the valve. The

outlet valve can be closed at any time.

12) Before removing any components attached to the outlet valve, always close the outlet valve by positioning the valve handle

perpendicular to the valve.

13) Before connecting new component to the compressor outlet valve, first close the outlet valve by positioning the valve handle

perpendicular to the valve. Disconnect the component connected on the outlet valve and then connect the new component.

Follow the components operating manuals.

14) After finishing work, close the compressor outlet valve by positioning the valve handle perpendicular to the valve.

15) Turn the compressor switch to the "OFF" position.

16) Disconnect the compressor from the power supply.

The compressor should stand on its feet on a level and stable surface, in a dry, clean, dust-free and well-ventilated place. The

distance of the compressor side surfaces from other objects should not be less than 5 cm. The distance of the front and back

of the compressor from other objects should not be less than 10cm. It is necessary to provide free air inlet to the device from

the pump fan side, and to allow free air intake through the air intake with a silencer.

Do not allow the compressor pump to overheat. Exceeding the temperature of 100⁰C on the motor housing significantly

shortens the life of the pump, and in some cases may lead to its complete damage.

If the compressor will not be used for a long period of time, release the compressed air from the tank, cover the compressor,

and then put it in a dry and safe place.

The compressor works without oil. The compressor must not be filled with oil or lubricated, as this may damage the

compressor.

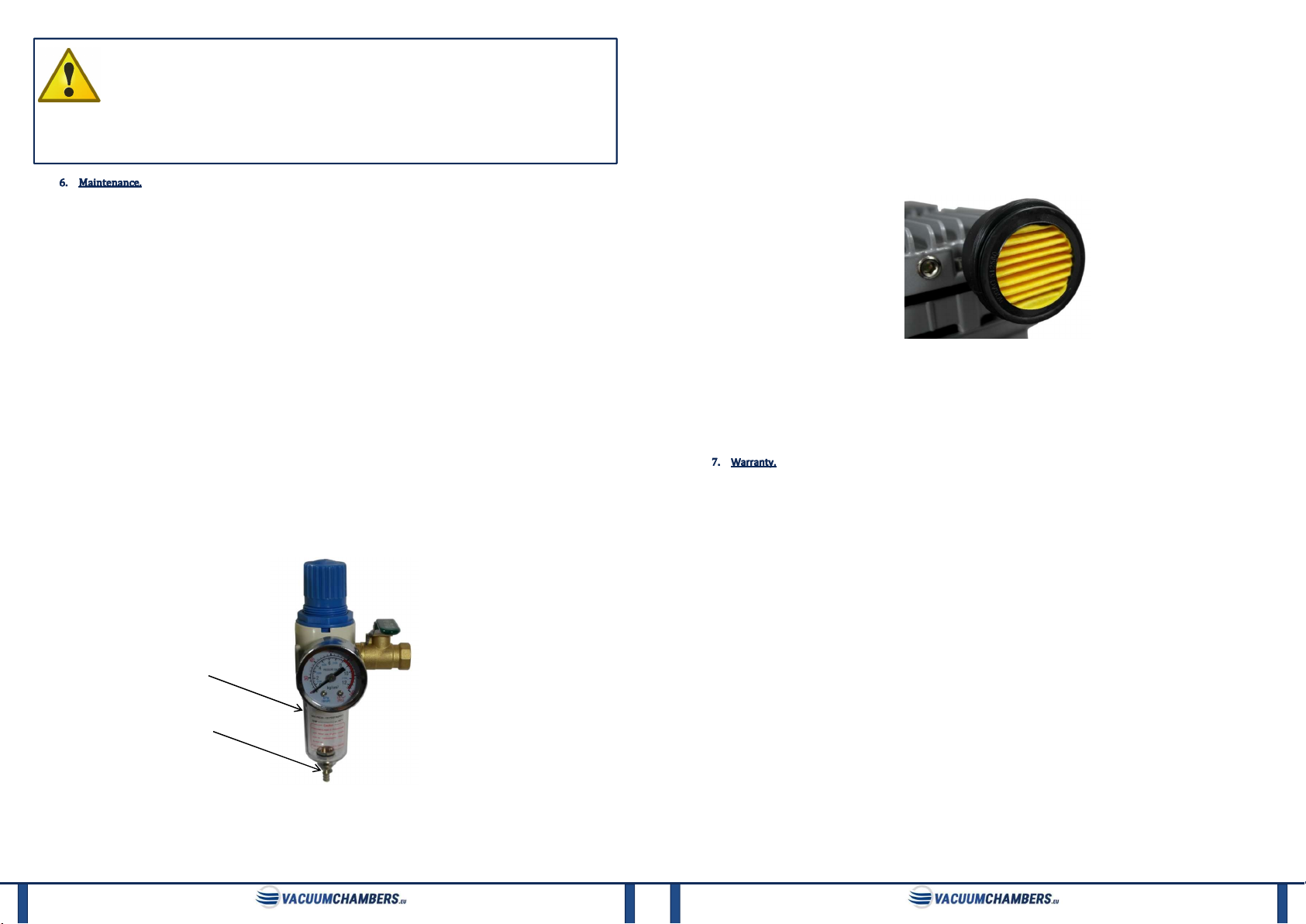

To protect the inside of the tank from corrosion, open the bottom drain valve daily to remove moisture and water that may

have accumulated in the tank due to air compression.

6

If it is not possible to achieve an pressure value as declared by the distributor, this may indicate a leak in the system. Make

sure that all compressor components are tightly connected and work properly. Close the outlet valve (position valve handle

perpendicular to the valve) when checking the compressor for leaks.

If the compressor pump does not start, reduce the pressure in the tank below 4 bar relative pressure.

The compressor is intended to be used only as a source of compressed air. Its use for other purposes is prohibited.

If the safety valve has been activated, check if the rated value in the tank is not exceeded during operation of the device.

The compressor pump is an oil-free piston pump, therefore it is not designed to continuous work. Continuous operation of

the pump may cause it to overheat. In this case, the pump will be automatically turned off. It will be possible for the pump to

resume operation after it has cooled down. This should happen after about 15 minutes of break.

When the power cord is connected to the power supply, the switch is in the "ON" position and the relative pressure in the

tank is less than 5 bar, the pump starts automatically without any warning.

When the pump is turning off, air is blown out of the solenoid valve.

Read the operating instructions before use.

There are warning decals on the compressor pump and the pressure tank, read them before starting work and

follow them.

Before each use of the air compressor, it is necessary to check its technical condition, in particular the supply

cable.

In the event of unusual sounds, exclude compressor from use - possible damage to internal components. Perform servicing

and maintenance of the air compressor periodically.

Carry out all maintenance work when the compressor pump is not hot and air compressor is not running, and is

disconnected from the power supply.

The general rules for the use of equipment working under voltage must be observed.

Before starting work, make sure that the parameters of the power source correspond to the air compressor requirements

specified on the compressor pump.

Make sure that the air compressor complies with the technological requirements, processes and purposes for which it is

to be used. Make sure that the air compressor is not exposed to chemicals that could damage it. The customer is solely

responsible for selecting the appropriate air compressor for the working conditions.

Make sure that the components, with which the compressor will cooperate are suitable for the pressure generated by the

compressor and are in good condition.

Do not compress flammable, explosive and toxic gases. It also cannot operate in the environment in which such gases are

found.

The temperature of compressed gases should not be higher than + 70°C.

A pressure value of 8 bar must not be exceeded. It is not allowed to make any changes to the safety valve.

Use the air compressor in a safe, well-ventilated place, on a flat, stable surface.

The compressor is not intended for use in a potentially explosive atmosphere and is not protected with high voltage

resistant insulation.

Avoid excessive pollution of the working environment by dust, powders, small solids or water, as heavy contamination can

damage the air compressor.

Depressurize the pressure tank prior to transport and storage.

Do not expose the device to rain or excessive moisture.

Some parts of the compressor pump get very hot during operation. To prevent burns, never touch the body and pump

motor.

Never place in close proximity to the compressor objects flammable, explosive, and susceptible to high temperature.

Do not repair the compressor by yourself.

It is not allowed to modify the compressor's factory settings.

Wear hearing protection in case of prolonged use of the compressor.

Never put fingers or other objects inside the pump impeller cover. Keep your hair, clothing, gloves and other objects that

could get into the impeller, away from moving parts.

Do not subject any parts of the human body to overpressure.

Do not direct the pressure hose or the compressed air jet towards people or animals.