VAG Operation and Maintenance Instructions • 3

VAG HYDRUS®G Underground Hydrant.

Observing these Operation and Maintenance Instructions helps

you to:

• Prevent hazards

• Reduce repair costs and down-times of the valve and/or the

entire equipment

• Improve the operational safety and useful life of the equipment.

1.3 Identification

According to DIN EN 19 all valves bear an identification label

specifying the nominal diameter (DN), nominal pressure (PN),

body material and the manufacturer’s logo.

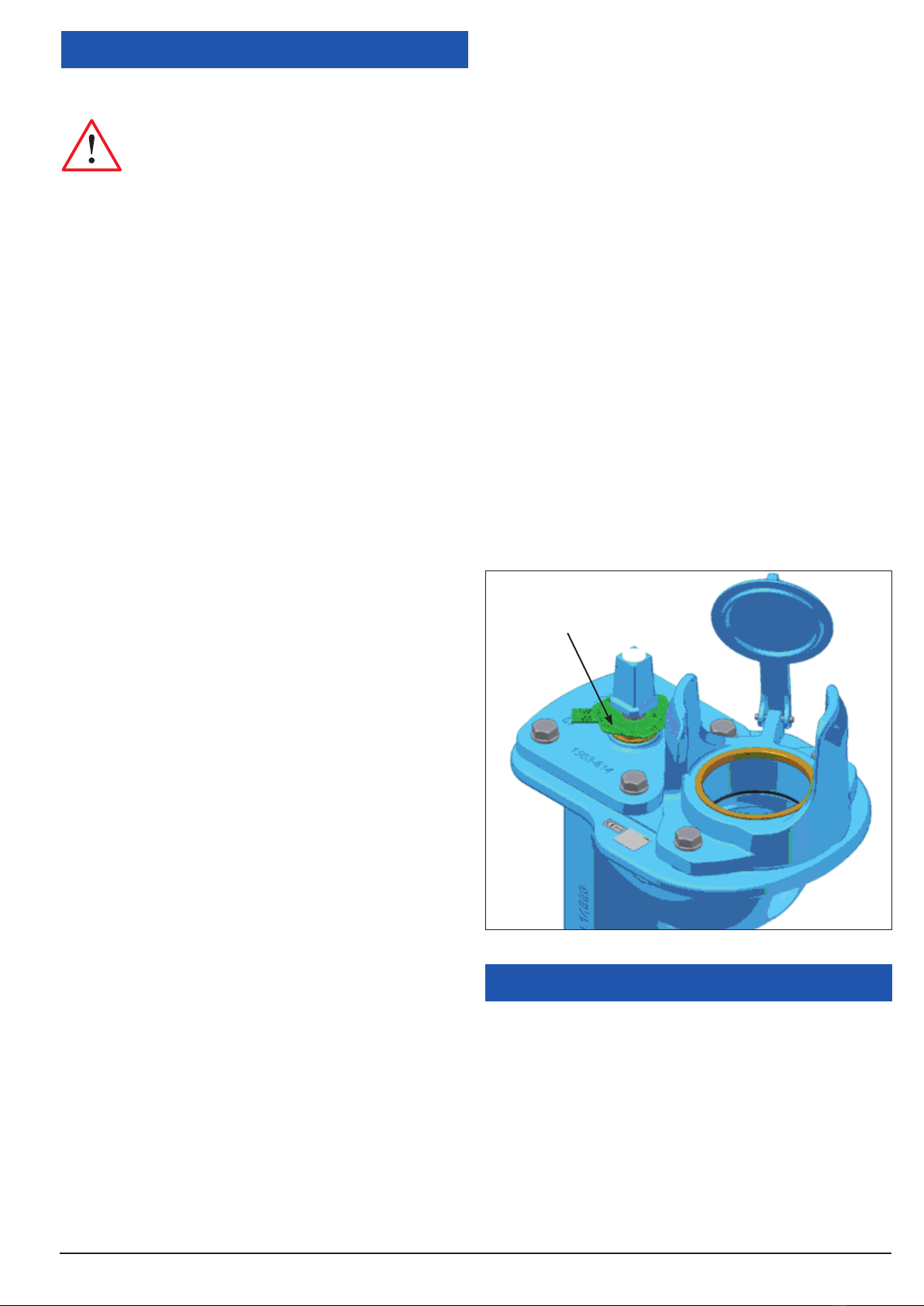

After installation in the pipeline cap, the following information can

been seen on the name plate when viewed from above.

VAG Manufacturer’s name

DN Nominal diameter of the valve

PN Nominal pressure of the valve

Installation depth (important for spare part definition)

Date of manufacture

2 Transport and Storage

2.1 Transport

For transportation to its installation site, the valve must be packed

in stable packaging material suitable for the size of the valve. It

must be ensured that the valve is protected against atmospheric

influences and external damage. When the valve is shipped under

specific climatic conditions (e.g. overseas transport), it must be

specially protected and wrapped in plastic film and a desiccant

must be added.

The factory-applied corrosion protection and any assemblies

must be protected against damage by external influences during

transport and storage.

1 General

1.1 Safety

These Operation and Maintenance Instructions must

be observed and applied at all times along with the

general “VAG Installation and Operation Instructions

for Valves” (see www.vag-group.com / Category: In-

stallation and Operation Instructions).

Arbitrary alterations of this product and the parts supplied with it

are not allowed. VAG will not assume any liability for consequen-

tial damage due to non-compliance with these instructions.

When using this valve, the generally acknowledged rules of tech-

nology have to be observed (e.g. national standards, EN 1074-6

hydrants, fitness for purpose requirements and appropriate veri-

fication tests, etc.). The installation must only be carried out by

qualified staff (see also Section 6.1 General safety instructions).

For further technical information such as dimensions, materials or

applications, please refer to the respective documentation (KAT

1622-A).

VAG valves are designed and manufactured to the highest stand-

ardst and their safety of operation is generally ensured. However,

valves may be potentially dangerous if they are operated improp-

erly or are not installed for their intended use.

Everyone dealing with the assembly, disassembly, operation,

maintenance and repair of the valves must have read and under-

stood the complete Operating and Maintenance Instructions (Ac-

cident Prevention Regulations, VBG 1 §§ 14 [Regulations issued

by the Trade Associations], ANSI Z535).

Before removing any protective devices and/or performing any

work on the valves, depressurise the pipeline section and ensure

it is free of hazards. Unauthorised, unintentional and unexpected

actuation as well as any hazardous movements caused by stored

energy (pressurised air, water under pressure) must be prevented.

In case of equipment that must be monitored and inspected, all

relevant laws and regulations, such as the Industrial Code, the

Accident Prevention Regulations, the Ordinance of Steam Boilers

and instructional pamphlets issued by the Pressure Vessels Study

Group must be complied with. In addition, the local accident pre-

vention regulations must be observed.

When a valve needs to be dismantled from a pipeline, fluid may

emerge from the pipeline or the valve. The pipeline must be emp-

tied completely before the valve is dismantled. Special care needs

to be taken in case of residues which may continue flowing.

1.2 Proper use

The VAG HYDRUS®G Underground Hydrant is a valve for installa-

tion in drinking water pipeline networks.

Refer to DVGW technical standard W331 for deployment and cor-

rect installation.

For the respective technical application ranges (e.g. operating

pressure, medium, temperature) please refer to the product-relat-

ed documentation (KAT 1622-A).

For any alternative operating conditions and applications, the

manufacturer’s written approval must be obtained!

These Operation and Maintenance Operation Instructions contain

important information on the safe and reliable operation of the

VAG name plate

Picture 1: VAG name plate