4Operating instructions 0020330792_00

1 Safety

1.1 Action-related warnings

Classification of action-related warnings

The action-related warnings are classified in

accordance with the severity of the possible

danger using the following warning symbols

and signal words:

Warning symbols and signal words

Danger!

Imminent danger to life or risk of

severe personal injury

Danger!

Risk of death from electric shock

Warning.

Risk of minor personal injury

Caution.

Risk of material or environmental

damage

1.2 Intended use

There is a risk of injury or death to the user or

others, or of damage to the product and other

property in the event of improper use or use

for which it is not intended.

The product is the outdoor unit of an air-to-

water heat pump with monoblock design.

The product uses the outdoor air as a heat

source and can be used to heat a residential

building and for domestic hot water genera-

tion.

The air that escapes from the product must

be able to flow out freely, and must not be

used for any other purposes.

The product is only intended for outdoor in-

stallation.

The product is intended exclusively for do-

mestic use.

Intended use includes the following:

–observance of the operating instructions

included for the product and any other

installation components

–compliance with all inspection and main-

tenance conditions listed in the instruc-

tions.

This product can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental capabil-

ities or lack of experience and knowledge if

they have been given supervision or instruc-

tion concerning use of the product in a safe

way and understand the hazards involved.

Children must not play with the product.

Cleaning and user maintenance work must

not be carried out by children unless they are

supervised.

Any other use that is not specified in these

instructions, or use beyond that specified in

this document, shall be considered improper

use. Any direct commercial or industrial use

is also deemed to be improper.

Caution.

Improper use of any kind is prohibited.

1.3 General safety information

1.3.1 Risk of death caused by fire or

explosion if there is a leak in the

refrigerant circuit

The product contains the combustible refri-

gerant R290. In the event of a leak, escaping

refrigerant may mix with air to form a flam-

mable atmosphere. There is a risk of fire and

explosion.

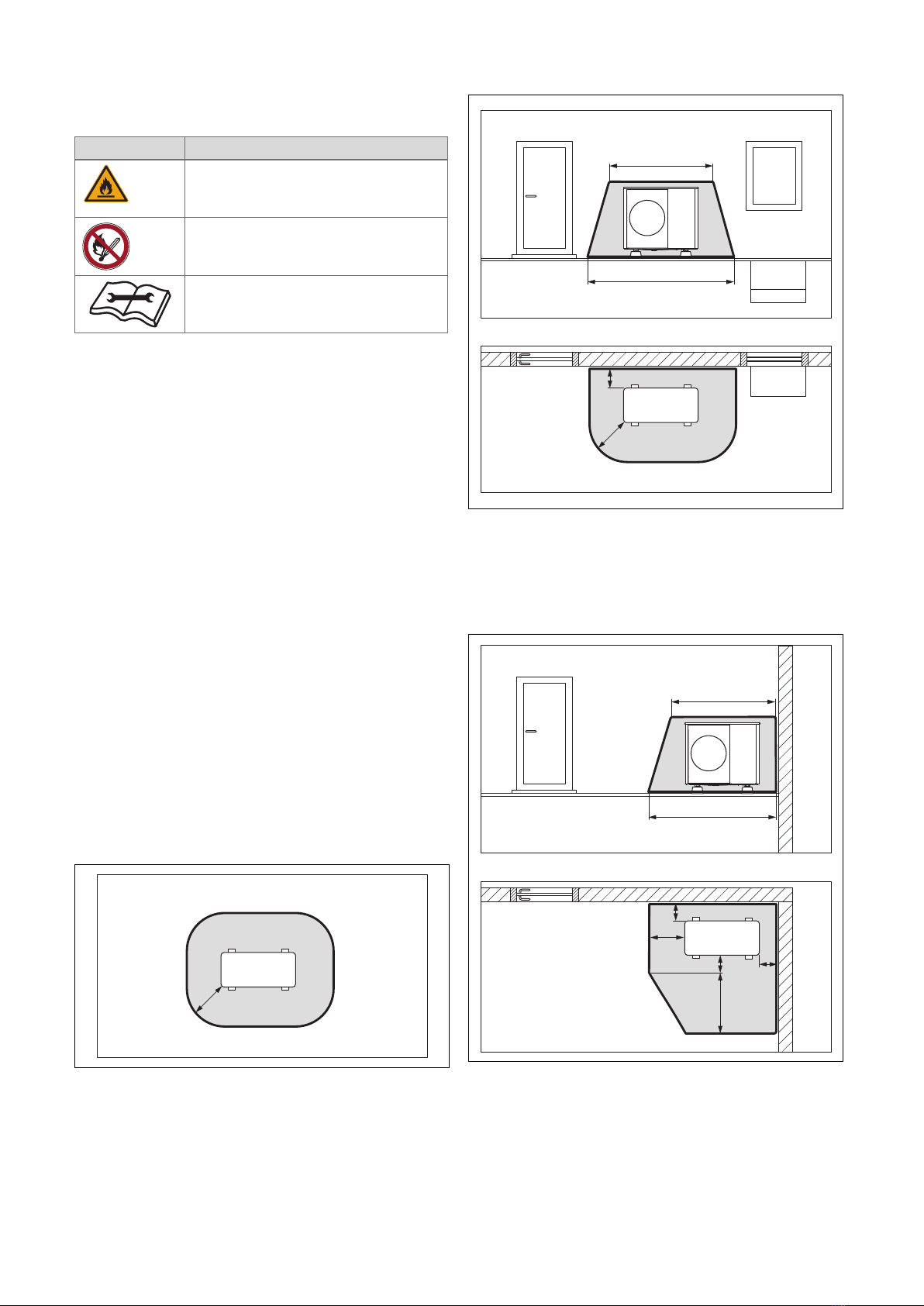

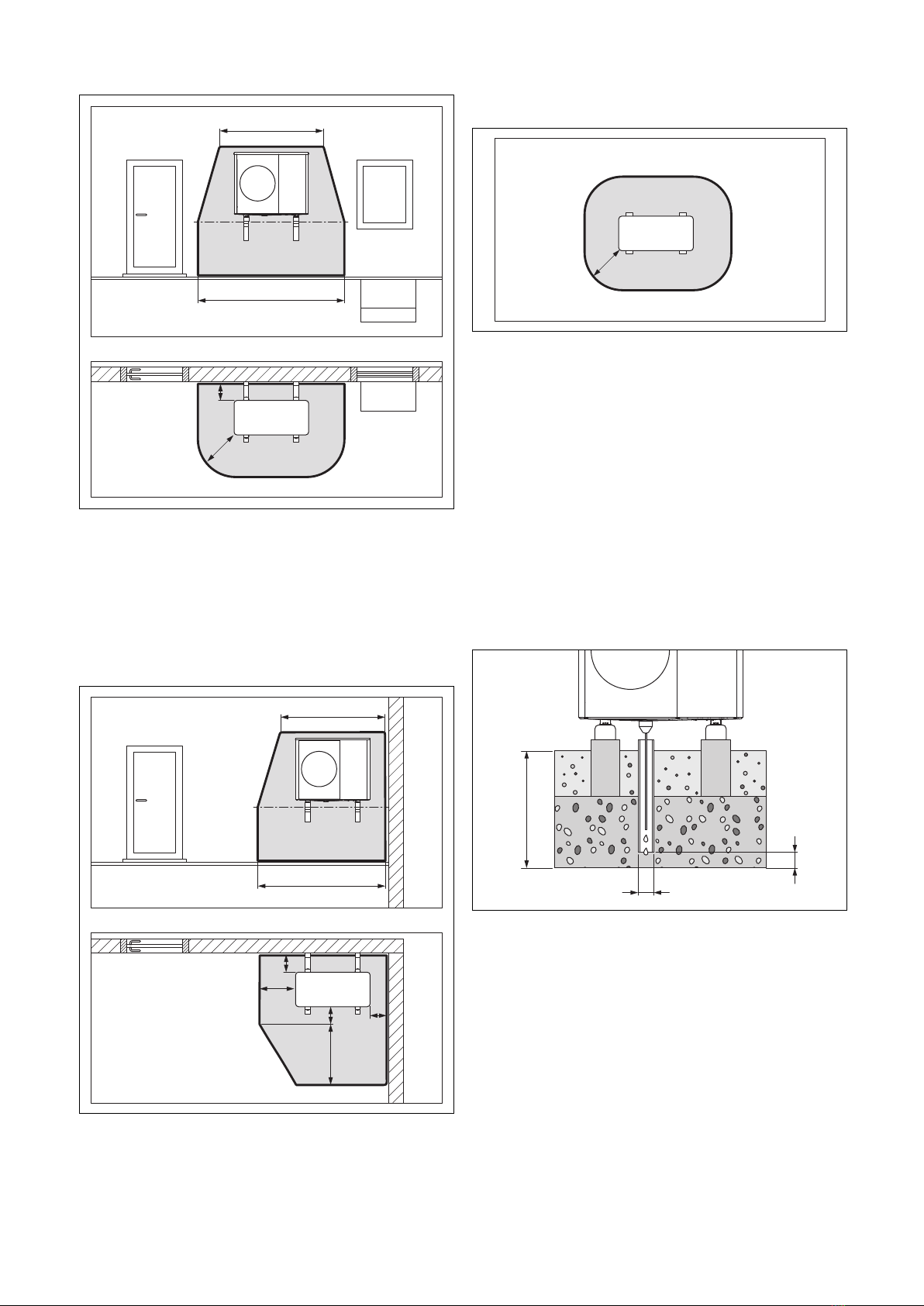

A protective zone is defined for the area

close around the product. See section

"Protective zone".

▶Ensure that there are no ignition sources,

such as plug sockets, light switches,

lamps, electrical switches or other per-

manent ignitions sources, in the protective

zone.

▶Do not use any sprays or other combust-

ible gases in the protective zone.

1.3.2 Risk of death due to changes to the

product or the product environment

▶Never remove, bridge or block the safety

devices.

▶Do not tamper with any of the safety

devices.

▶Do not damage or remove any tamper-

proof seals on components.

▶Do not make any changes:

–The product itself

–To the supply lines

–On the drain pipework

–On the expansion relief valve for the

heat source circuit