Valcom PagePac V-5331215A User manual

Other Valcom Horn manuals

Valcom

Valcom FLEXHORN V-1090 User manual

Valcom

Valcom V-1030C Manual

Valcom

Valcom VIP-148AL-SA Syn-Apps User manual

Valcom

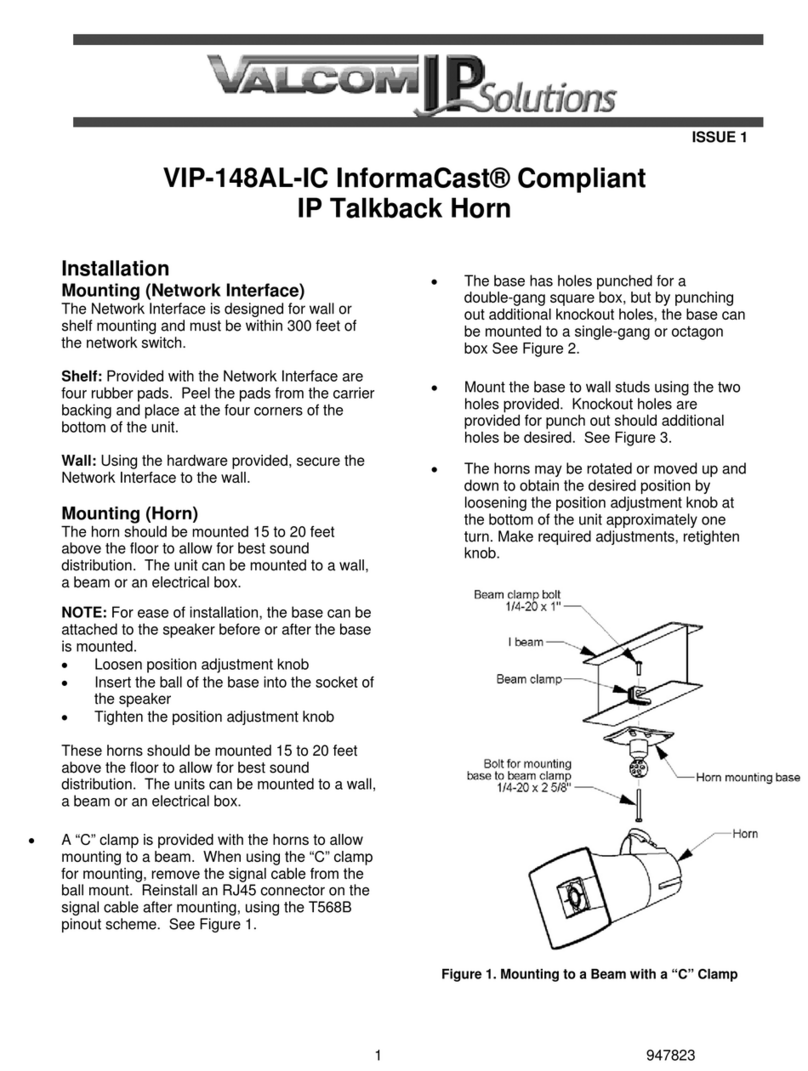

Valcom VIP-148AL-IC User manual

Valcom

Valcom V-9925A User manual

Valcom

Valcom V-1080 Flexhorn User manual

Valcom

Valcom InformaCast VIP-480L-IC User manual

Valcom

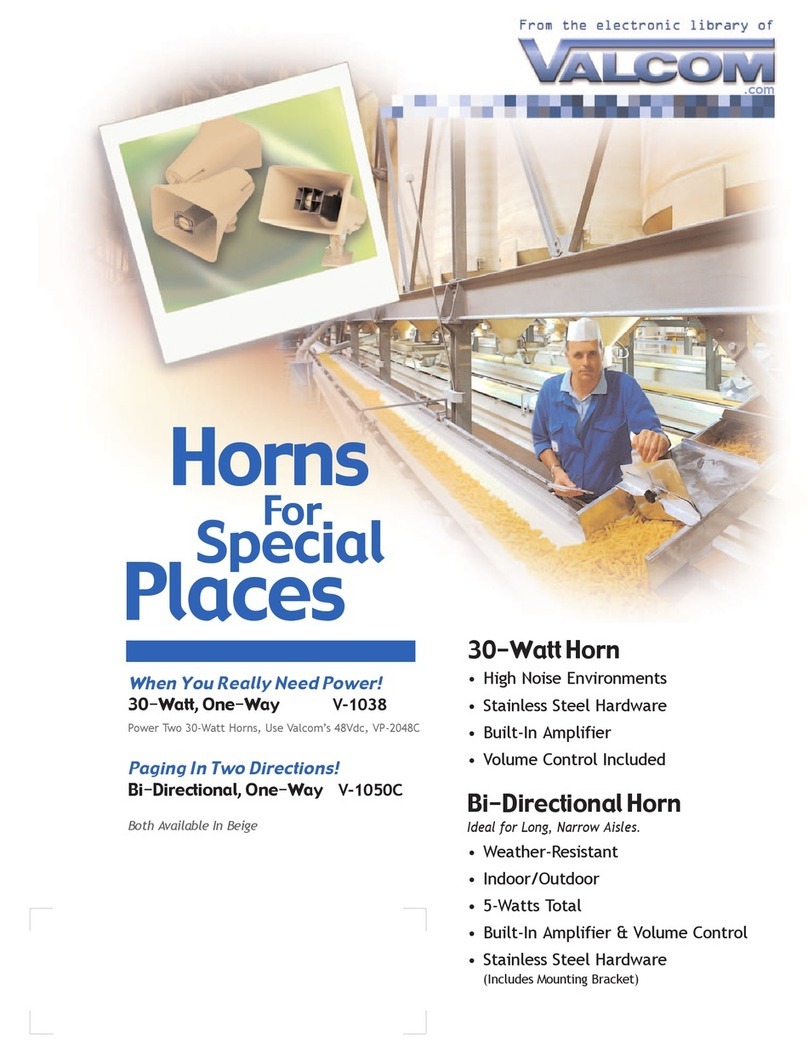

Valcom V-1038 User manual

Valcom

Valcom VIP-480L User manual

Valcom

Valcom V-1030C User manual

Valcom

Valcom VIP-130L-IC User manual

Valcom

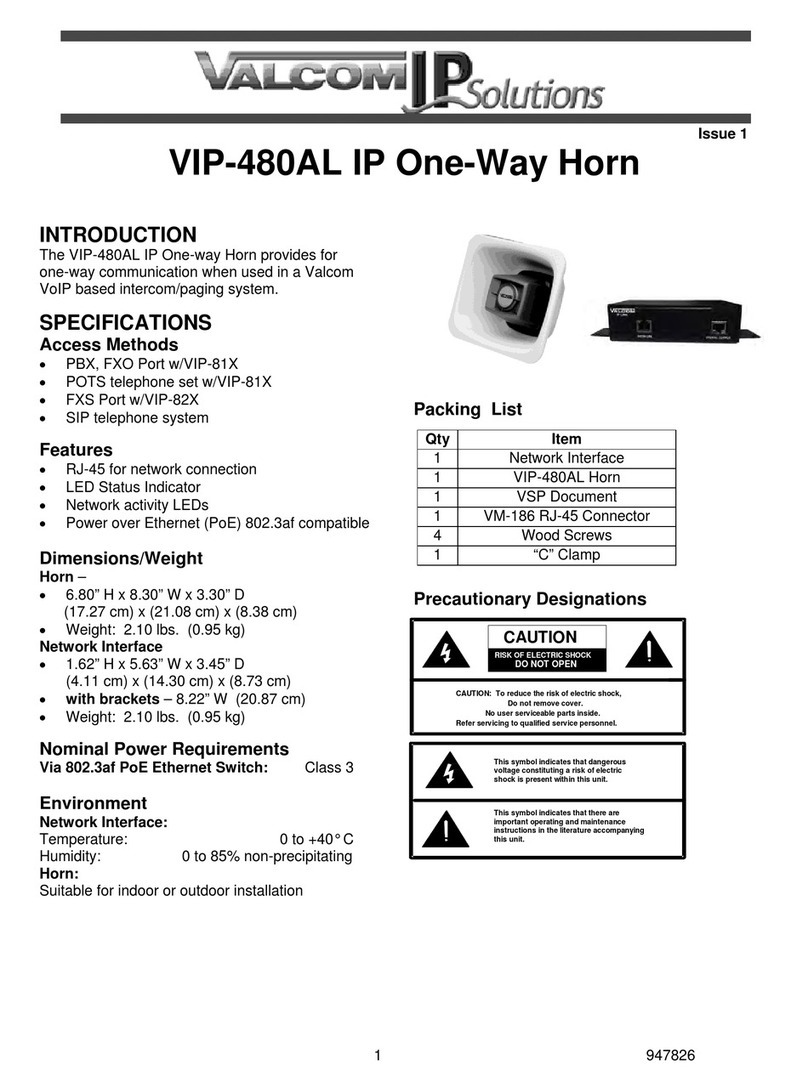

Valcom VIP-480AL User manual

Valcom

Valcom VIP-9831AL User manual

Valcom

Valcom VIP-480L User manual

Valcom

Valcom V-1090 Flexhorn User manual

Valcom

Valcom VIP-130AL-IC User manual

Valcom

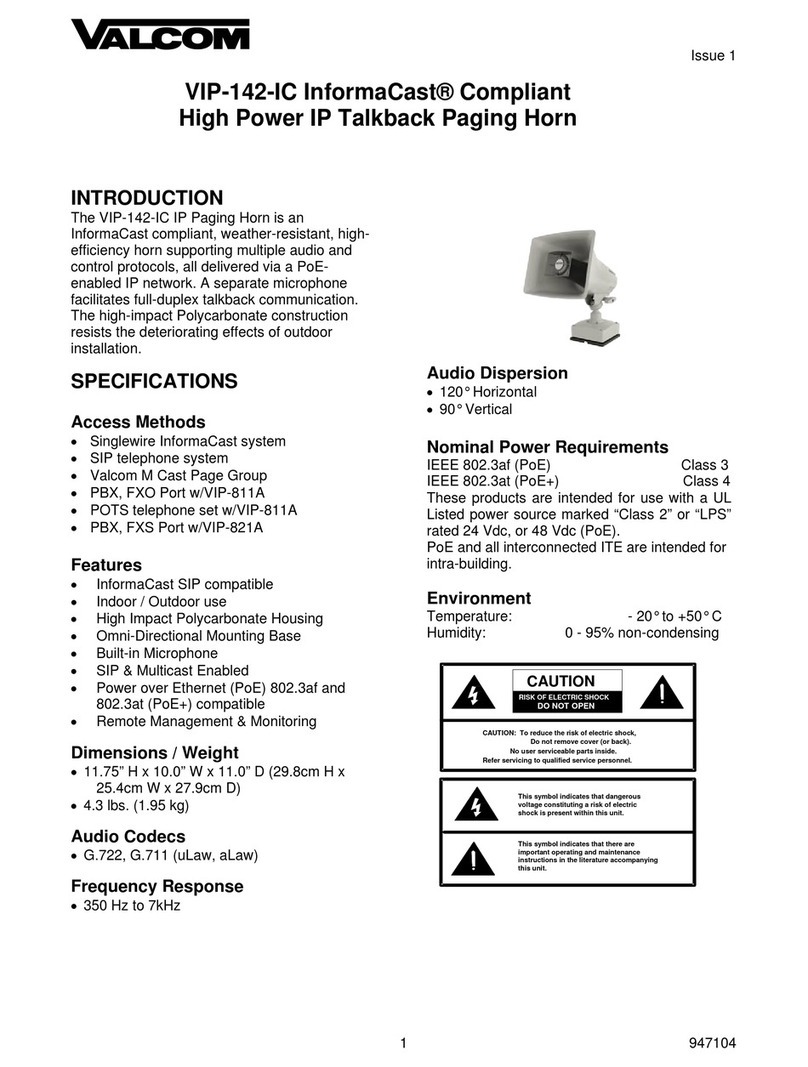

Valcom InformaCast VIP-142-IC User manual

Valcom

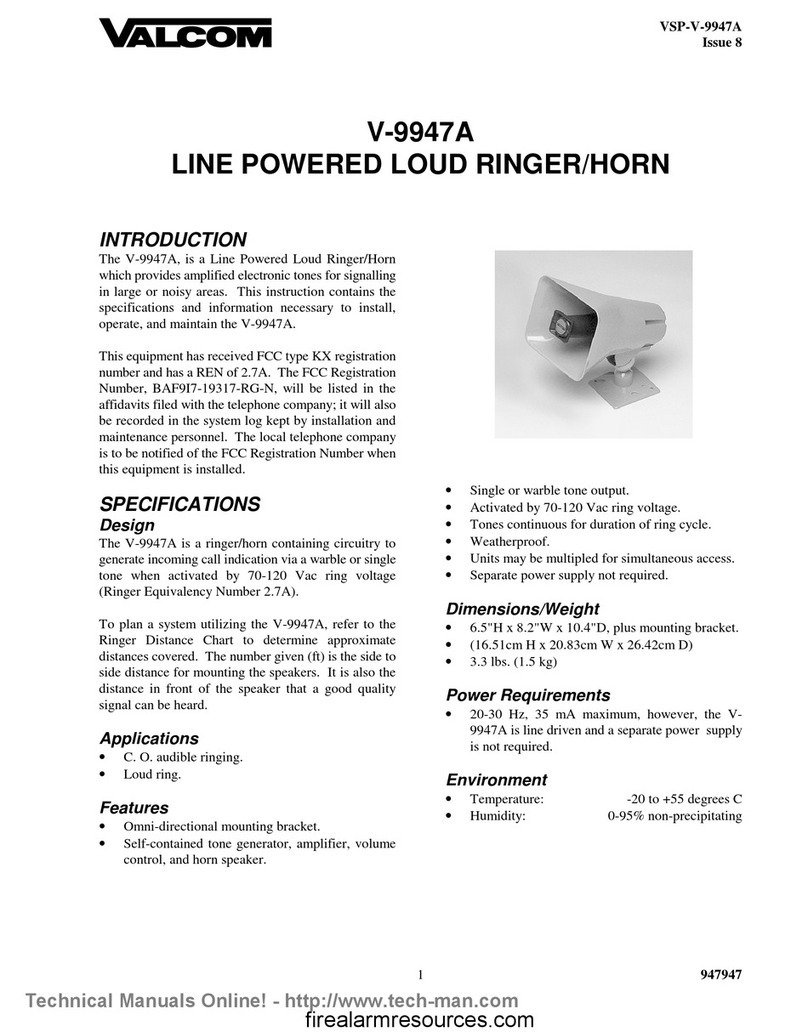

Valcom V-9947A User manual

Valcom

Valcom PagePac V-5331200 User manual

Valcom

Valcom V-1050C User manual

Popular Horn manuals by other brands

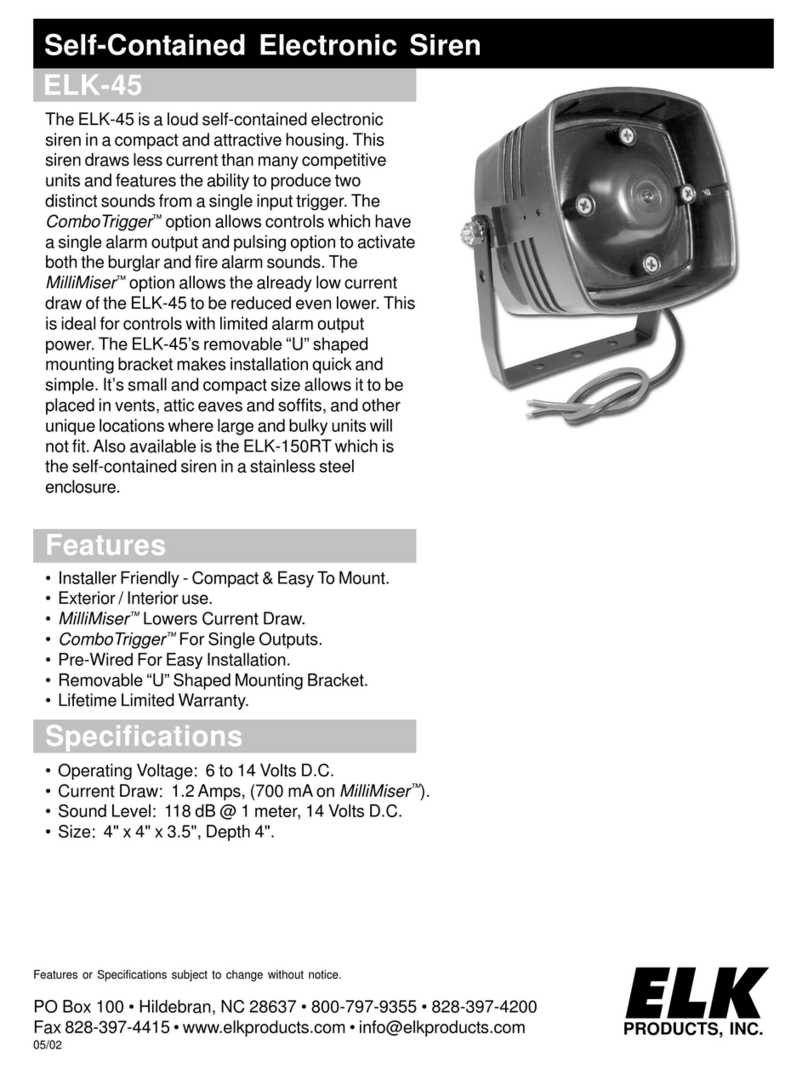

Elk Products

Elk Products 45 user manual

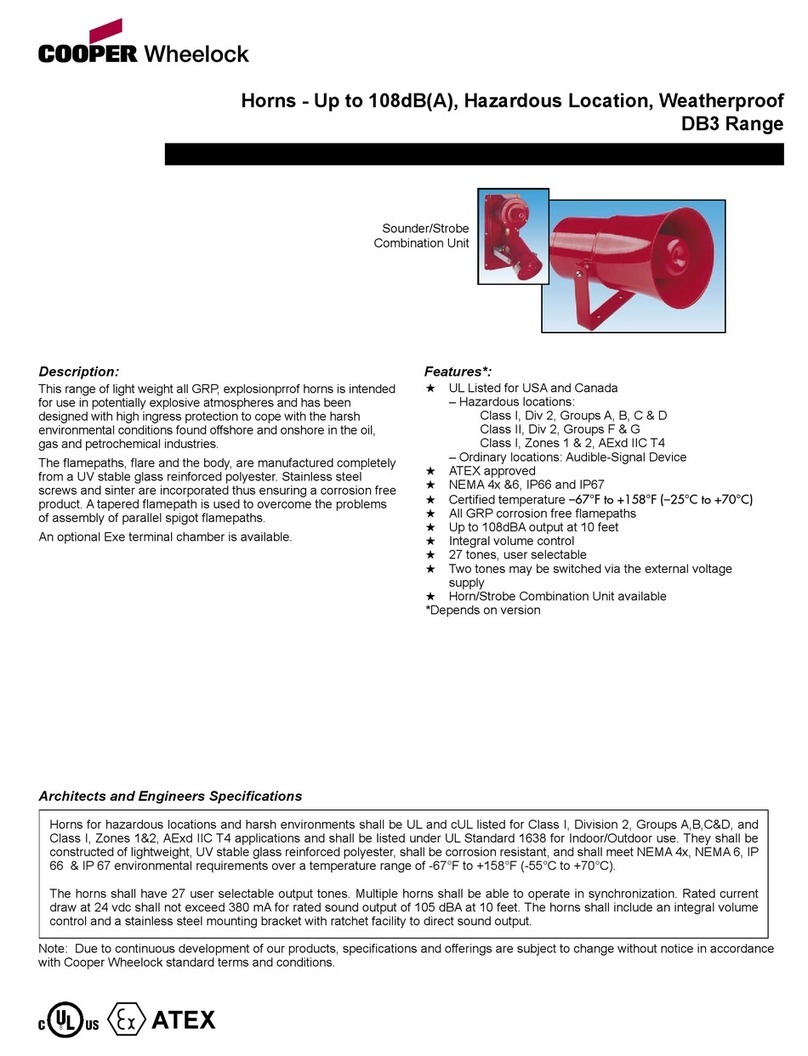

Cooper Wheelock

Cooper Wheelock DB3 Series specification

Altec Lansing

Altec Lansing 811B HF HORN manual

RF Elements

RF Elements UltraHorn CC Series quick start guide

Edwards Signaling

Edwards Signaling 869DSTR-G1 Series Installation sheet

Electro-Voice

Electro-Voice HPT94 specification

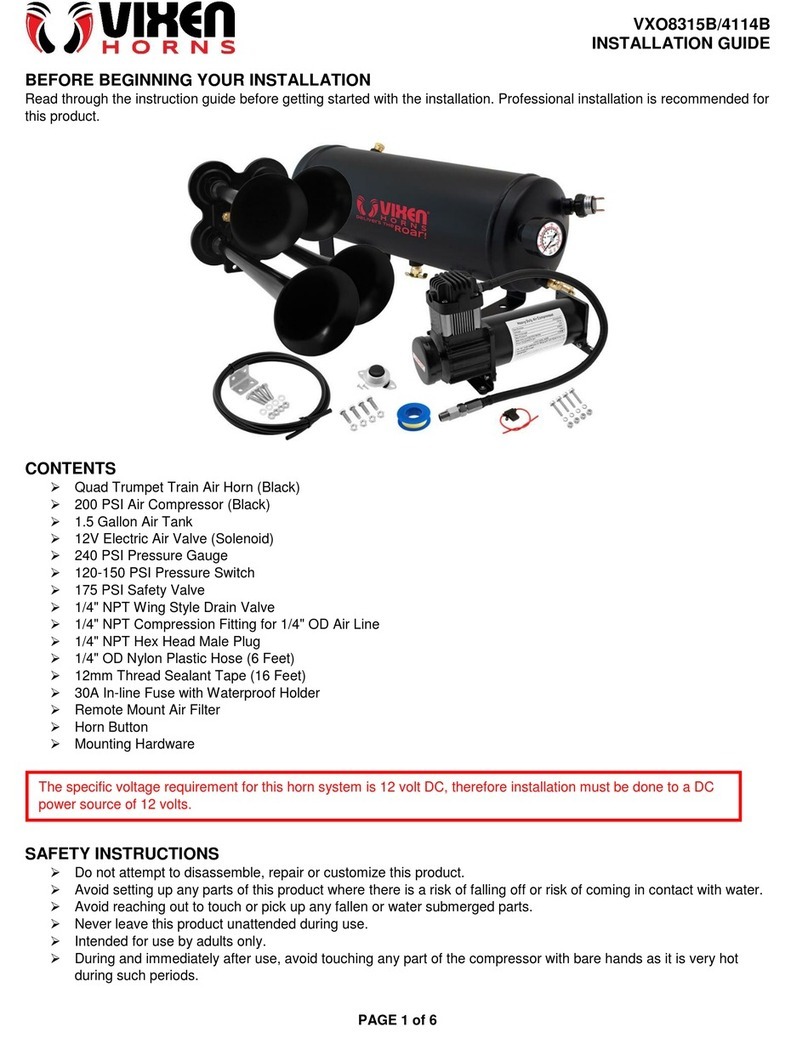

Vixen Horns

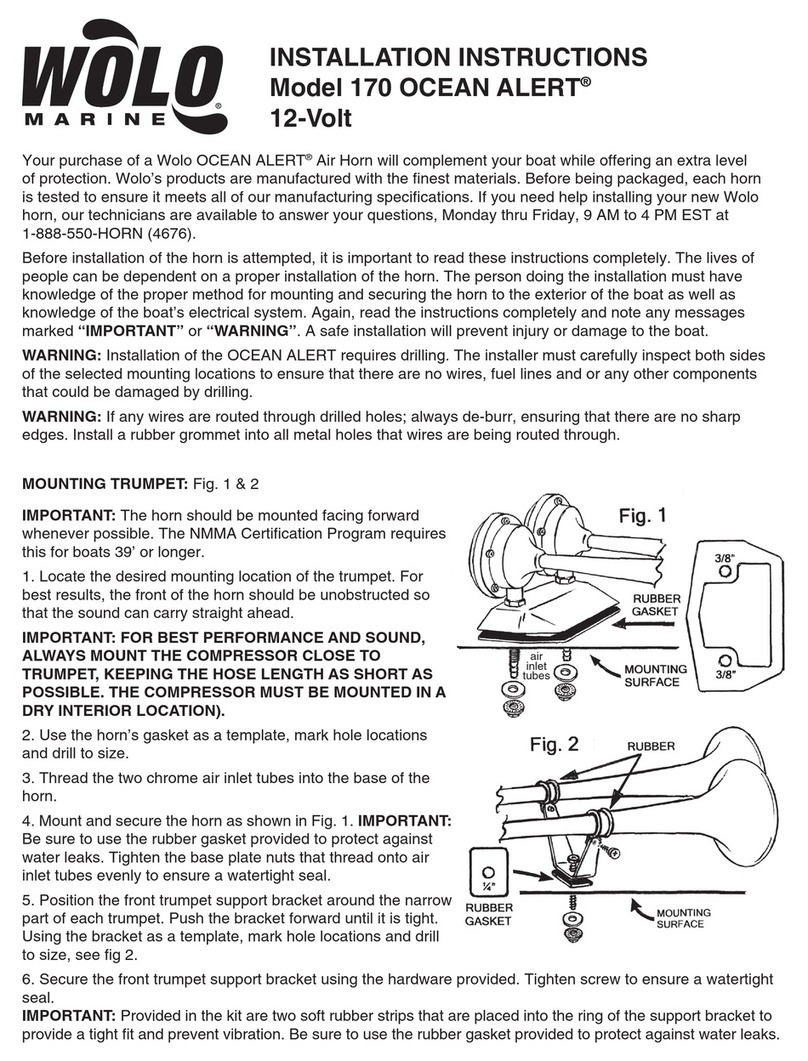

Vixen Horns VXO8315B/4114B installation guide

Altec

Altec 151A PAGING HORN manual

aidapt

aidapt VM953 Usage and maintenance instructions

auna

auna MEG1-HY quick start guide

ACR Electronics

ACR Electronics ACR-EM-1A - REV Y Product support manual

Behringer

Behringer Eurosound Megaphone XT quick start guide