Page 1 of 14

GEN2-V1 10-ft Instructions (Generic) doc:r1

RETRACTABLE PATIO SHADE AWNING

Patio Awning Guide-8ft.x10ft.(Proj. X Width)

Model: APR-100810***/APR-60020810 (version: GEN2-V1)

1. INTRODUCTION:

Thank you for purchasing a Retractable Shade Awning.Before proceeding, please ensure that all the parts are in

the box, as listed below:

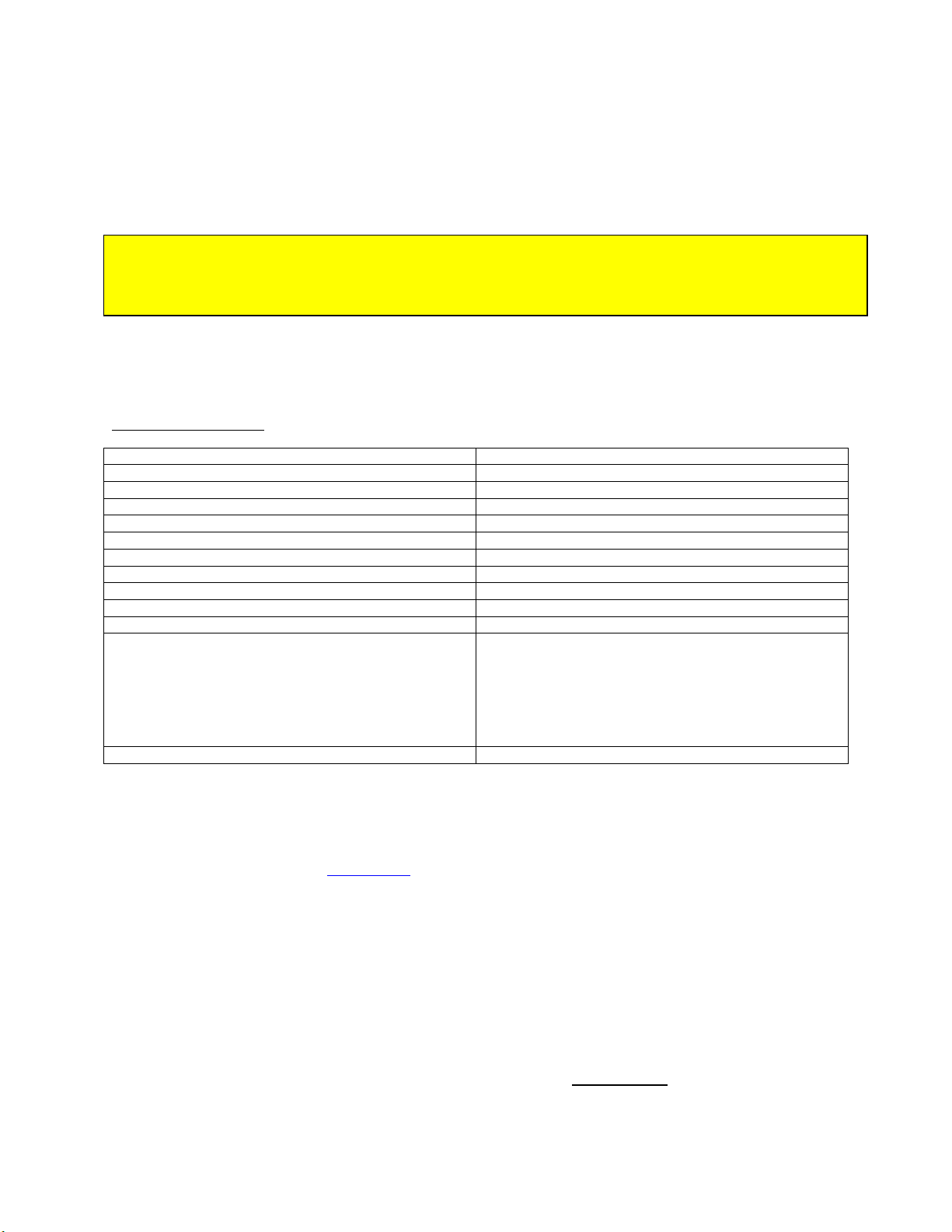

Master Carton Contents:

labeled LEFT WALL BRACKET ASSEMBLY

labeled RIGHT WALL BRACKET ASSEMBLY

labeled GEAR MECH. & Support Bracket

150 cm Roller Tube, w/Square Drive

150 cm Roller Tube, w/Round Drive

150 cm Valance Tube, drilled left

150 cm Valance Tube, drilled right

50 mm Valance Tube Joiner, drilled

312cm Plastic Spline (coiled)

Bubble Bag, labeled MISC. PARTS, includes:

-2-Wrist Assemblies

-2-Position Poles

-Level

-6-Spline Stops

-Right & Left Valance Tube End Caps

-2-Bags of 4-pcs 1/2” x3” Sleeve Anchors

In the event that there is ANY part missing or damaged, please DO NOT RETURN THE PRODUCT TO YOUR

RETAILER. By returning the product to your retailer we can not assist you in getting your awning properly installed.

Call our TOLL FREE Customer Service Hotline at 1-888-875-4844 for parts or replacement of parts that may have

been damaged when shipped.

You may also go to our website at www.valor.ca in the Valor Shade/Patio Awning section for all assembly and

installation instructions, set up, adjustment, and troubleshooting instructions. There you will be able to see common

problems and how to rectify them usually with a simple adjustment. You may also use this section to email us your

questions, and during business hours between 9:00 AM and 4:00 PM EST you will be able to connect with a

customer service representative for assistance.

2. PRODUCT:

The Valor Shade Awning is a unique program that allows you to order awnings that are modular in design making

them easier to transport . The product is offered with your choice of several available patterns (sold separately). The

product is factory configured with Left Side operation (when facing the house), but can be converted to right side

operation by following the steps outlined in this guide.

IMPORTANT WARNING:

Your new awning is intended as protection against the sun only. It is not to be used during periods of strong

wind, rain, hail, or snow. The warranty will not cover use during these periods. Bird droppings, pine needles,

and various air born materials that may settle on your awning; awning fabric should be cleaned using water

and a light soap. No abrasive cleansers or harsh chemicals should be used on the fabric. Damage to the

Awning (including the fabric) from any foreign material is not covered under our warranty.

WARNING:

DO NOT CUT THE PLASTIC ZIP TIES ON THE AWNING EXTENSION ARMS UNTIL INSTRUCTED TO

DO SO IN THIS GUIDE. THE FOLDING ARMS ARE UNDER SPRING TENSION AND SHOULD NOT BE

CUT UNTIL THE AWNING IS FULLY ASSEMBLED AND INSTALLED ON THE WALL.