abcde

ADCA

VALSTEAM

ADCA

IMI M3HP.10 E 03.15

INSTALLATION AND MAINTENANCE INSTRUCTIONS

HIGH PURITY BALL VALVES

M3HP TRUE BORE

GENERAL

These instructions must be carefully read before any work involving products supplied by VALSTEAM ADCA

ENGINEERING S.A. is undertaken.

The installation procedure is a critical stage in a life of a valve and care should be taken to avoid damage to the

valve or equipment.

They give their maximum performance only when the equipment associated with them is correctly sized and

installed in accordance with our recommendations.

M3HP three pieces body ball valves are isolating valves designed for use on clean steam, condensate and

other gases and liquids used in high purity and aseptic processes. The valve is not designed as a control valve

and should be used only as an isolating valve, fully open or fully closed.

The product was mainly designed for the pharmaceutical, biotech, semiconductor, cosmetics, fine chemical,

food and beverage industries.

Note:

Current regional safety regulations should be take in to account and followed, while doing the installation and

maintenance work.

Handling, installation and maintenance work must be carried out by trained personnel. A supervisor must follow

and check all activities.

For the problems that cannot be solve with the help of this instructions, please contact the supplier or the

manufacturer.

The manufacturer reserves the right to change the design and material of this product without notice.

CE Marking: This product has been designed for use on water, clean steam and other liquids or gases which are in

Group 1 and 2 of the PED-European Pressure Equipment Directive 97/23/EC and it complies with those

requirements.

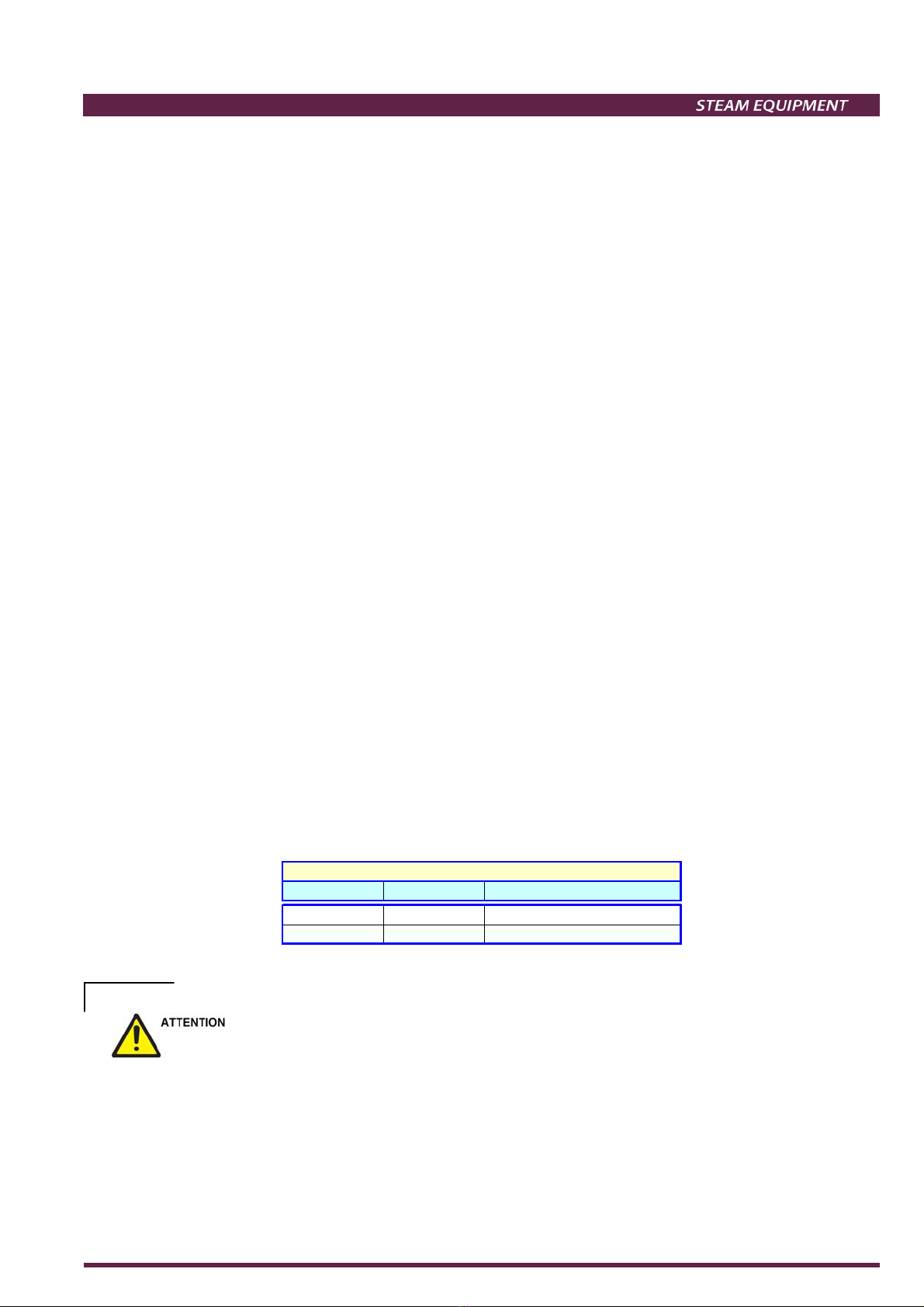

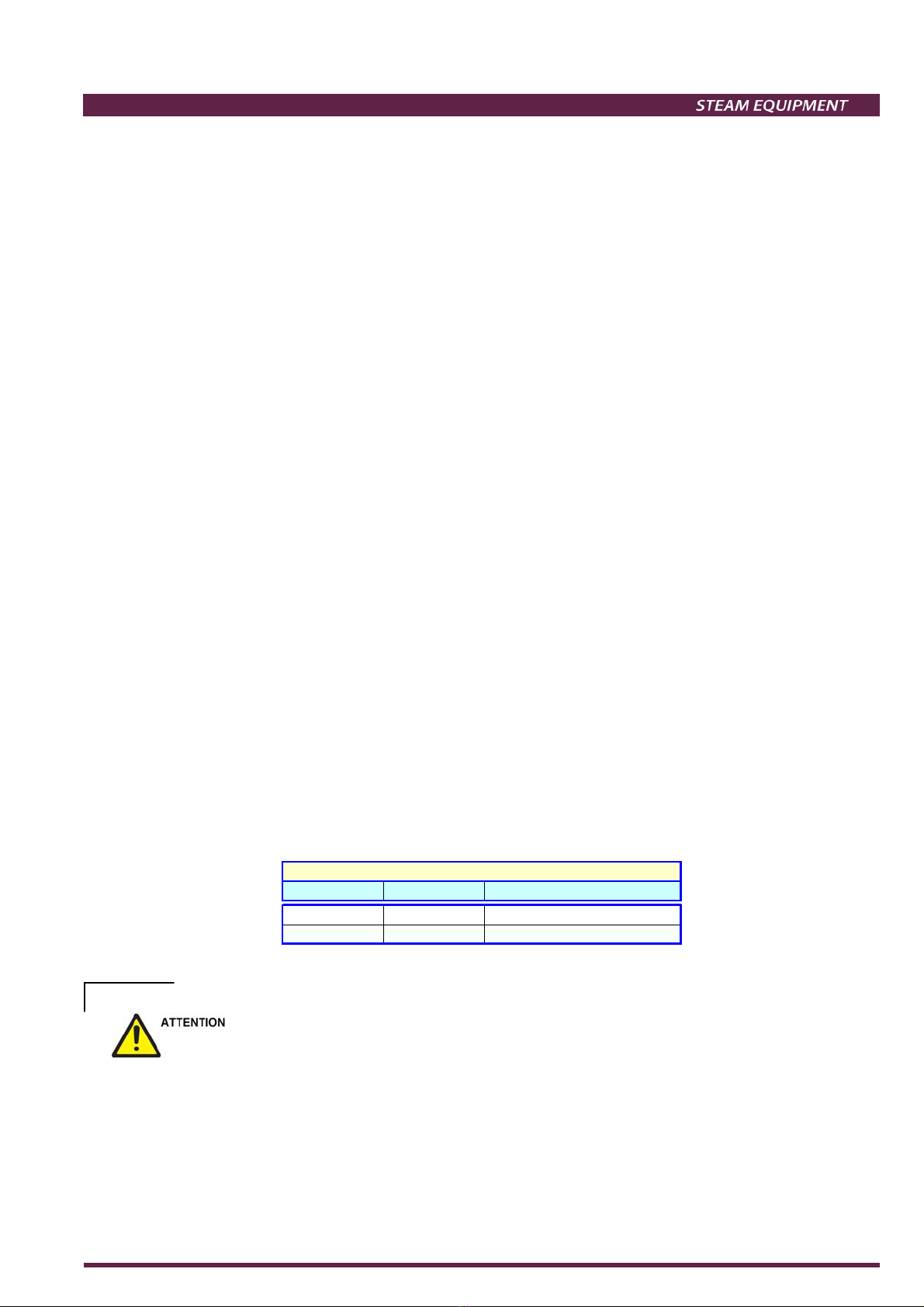

PN 100 PN 64 Category

DN 1/2" to 1" / SEP - art. 3, paragraph3

/ DN 11/2" -2" 1 (CE Marked)

CE MARKING (PED - European Directive 97/23/EC)

- If malfunction of any other equipment or system operation failure may result in a dangerous overpressure, over

temperature or even vacuum condition, a safety device must be included in the system to prevent such

situations.

- At start up, the presence of small particles in the fluid (dirt, scale, weld splatters, etc) may cause an imperfect

closure of the seat. If this occurs, proceed to an accurate cleaning.

- Do not touch the equipment without appropriate protection during working operation because it may conduct

heat if the used fluid is at high temperature.

- Before starting maintenance be sure that the equipment is not pressurized or hot.