Doc: iom5610.5616.onoff.trouble.0618 Cornelius, N.C. • USA www.valworx.com

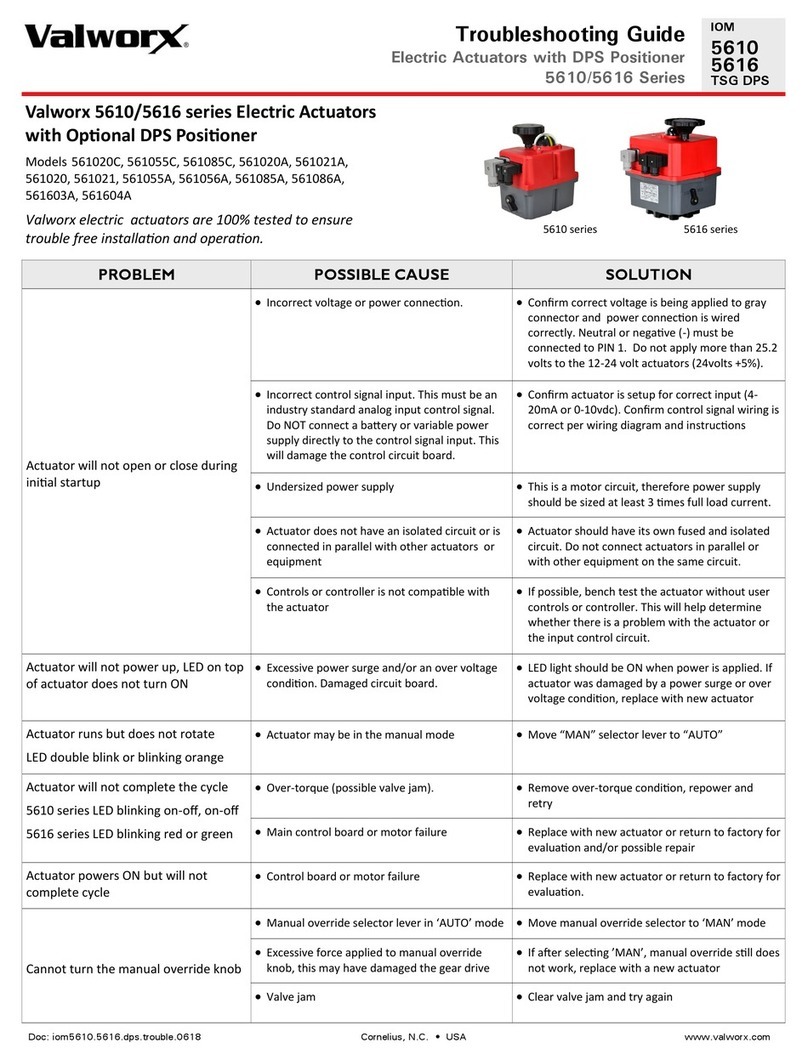

Troubleshooting Guide

Multi-Voltage On/Off Electric Actuators

5610/5616 Series

IOM

5610

5616

TSG On/Off

PROBLEM POSSIBLE CAUSE SOLUTION

Actuator will not open or close during

inial startup

Incorrect wiring of the gray DIN power

connector

Rewiring the gray DIN power plug per the

actuator electrical diagram and instrucons.

No suitable switching device Customer to supply a SPDT mechanical relay or a

3-way 2-posion manual switch to open and close

the actuator.

Incorrect voltage being supplied to actuator Conrm correct voltage is being applied to the

actuator. Connecng incorrect voltage may

damage the actuator beyond repair. Do not apply

more than 25.2 volts to the 12-24 volt actuators

(24volts +5%).

Power supply is not sized large enough This is a motor circuit, therefore power supply

should be sized at least 3 mes full load current.

Actuator does not have an isolated circuit or is

connected in parallel with other actuators or

equipment

Actuator should have its own fused and isolated

circuit. Do not connect actuators in parallel or

with other equipment on the same circuit.

Controls or controller is not compable with

the actuator. Leakage current from solid state

relays or contacts may cause actuator

malfuncon.

If possible, bench test the actuator without user

controls or controller. This will help determine

whether there is a problem with the actuator or

the input control circuit.

Actuator (valve) will close, but will not

open during inial startup. Slow LED

blink with DC voltage models.

Incorrect wiring of the gray DIN power

connector

Neutral or minus (-) power lead MUST be

connected to PIN 1 on gray power connector

(polarity sensive).

Actuator will not power up, LED on top

of actuator does not turn ON

Excessive power surge and/or an over voltage

condion. Damaged main circuit board.

LED light should be ON when power is applied. If

actuator was damaged by a power surge or over

voltage condion, replace with new actuator

Actuator runs but does not rotate

LED double blink or blinking orange

Actuator may be in the manual mode Move “MAN” selector lever to “AUTO”

Over-torque (possible valve jam). Remove over-torque condion, repower and try

again

Actuator will not complete the cycle

LED blinking on-o, red or green

Main control board or motor failure Replace with new actuator or return to factory for

evaluaon and/or possible repair

Valworx 5610/5616 series

On/O Electric Actuators

Models 561020C, 561055C, 561085C, 561020A,

561021A, 561020, 561021, 561055A, 561056A,

561085A, 561086A, 561603A, 561604A

Valworx electric actuators are 100% tested to

ensure trouble free installaon and operaon. 5610 Series 5616 Series