Revision: 2.3 Date: 10/30/20

G2-2

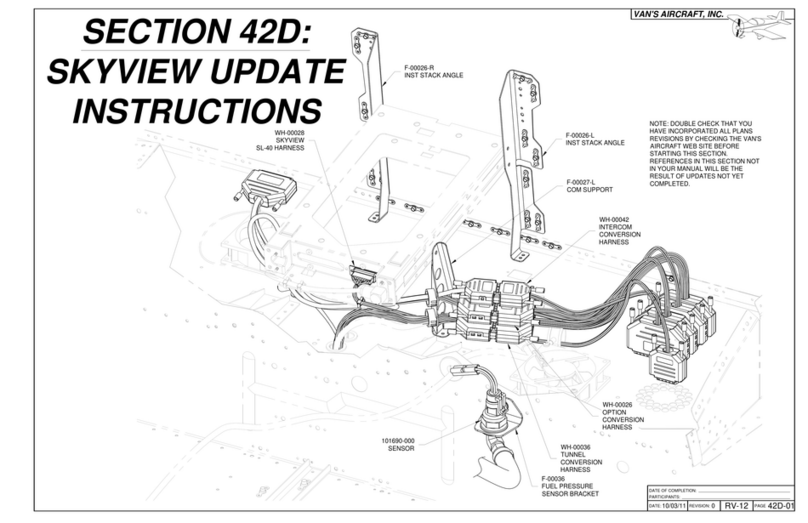

Standing alongside the stabilator, move stabilator from full-up to full-down and check for

binding/interference of the anti-servo tab and actuating mechanism.

Move the stabilator to the full trailing edge up position and hold it there.

Verify that there is at least 1/4 inch [6.3mm] clearance between the bottom of the rudder and

the AST pushrod.

Actuate trim switch to place the trim in the TAKEOFF position on the EFIS.

Move the stabilator to the full trailing edge up position and measure the tab position.

Distance from center of AST T.E. to center of stabilator T.E: (nominal

distance: 2.0 inches [50.8mm]) See Figure 3.

Turn the master switch “OFF”.

Install the empennage fairing.

Verify that there is no interference between the empennage fairing and the stabilator or anti-

servo tab pushrod at any point in their full ranges of travel.

Using a 12 inch or 30cm. straightedge, verify that:

The rudder skin, anti-servo tab, and stabilator skin are flat between the spar and trailing edge

and that there is no pillowing or bulging between ribs. (If necessary, re-shape trailing edge

bend using the procedure described in Section 5.7 of the KAI).

Ensure the trim tab is in the TAKEOFF position.

Move the rudder full left and hold against the stop.

Measure distance from bottom of rudder trailing edge to center of anti-servo pushrod with

stabilator held in full up position. Distance: inches (nominal distance: 7 1/8

inches [18.1cm] - measured horizontal, 7 5/16±1/8 inches [18.57±.3 cm] - measured

diagonally from point-to-point)

Move the rudder full right and hold against the stop.

Measure distance from bottom of rudder trailing edge to center of anti-servo pushrod with

stabilator held in full up position. Distance: inches (nominal distance: 7 1/8

inches [18.1cm] - measured horizontal, 7 5/16±1/8 inches [18.57±.3 cm] - measured

diagonally from point-to-point)

While seated in pilot seat, move rudder through its full range of motion.

Verify that when the left pedal is pushed, the rudder moves trailing edge left and when the

right pedal is pushed, the rudder moves trailing edge right.

Verify smooth movement of the rudder from stop-to-stop with no binding and little or no

friction.

Verify that the left flaperon moves trailing edge up when the stick is moved left and vice

versa.

Using a 12 inch or 30 cm. straightedge, verify that:

The flaperon skin is flat between the spar and trailing edge and that there is no pillowing or

bulging between ribs. (If necessary, re-shape trailing edge bend using the procedure detailed

in KAI Section 5.7).

Turn the master switch “ON”

Calibrate the Flap Position Indicator per the EFIS manual.

Cycle flaps through entire range. Verify smooth operation and position readout on EFIS.