Installation, Operating & Maintenance Instructions

Series 615 DN 40 (I.D. 1.5”), RS485

VAT Vakuumventile AG, CH-9469 Haag, Switzerland

Contents:

1Use of product .......................................................................................................................................................... 5

1.1 Technical data.................................................................................................................................................. 6

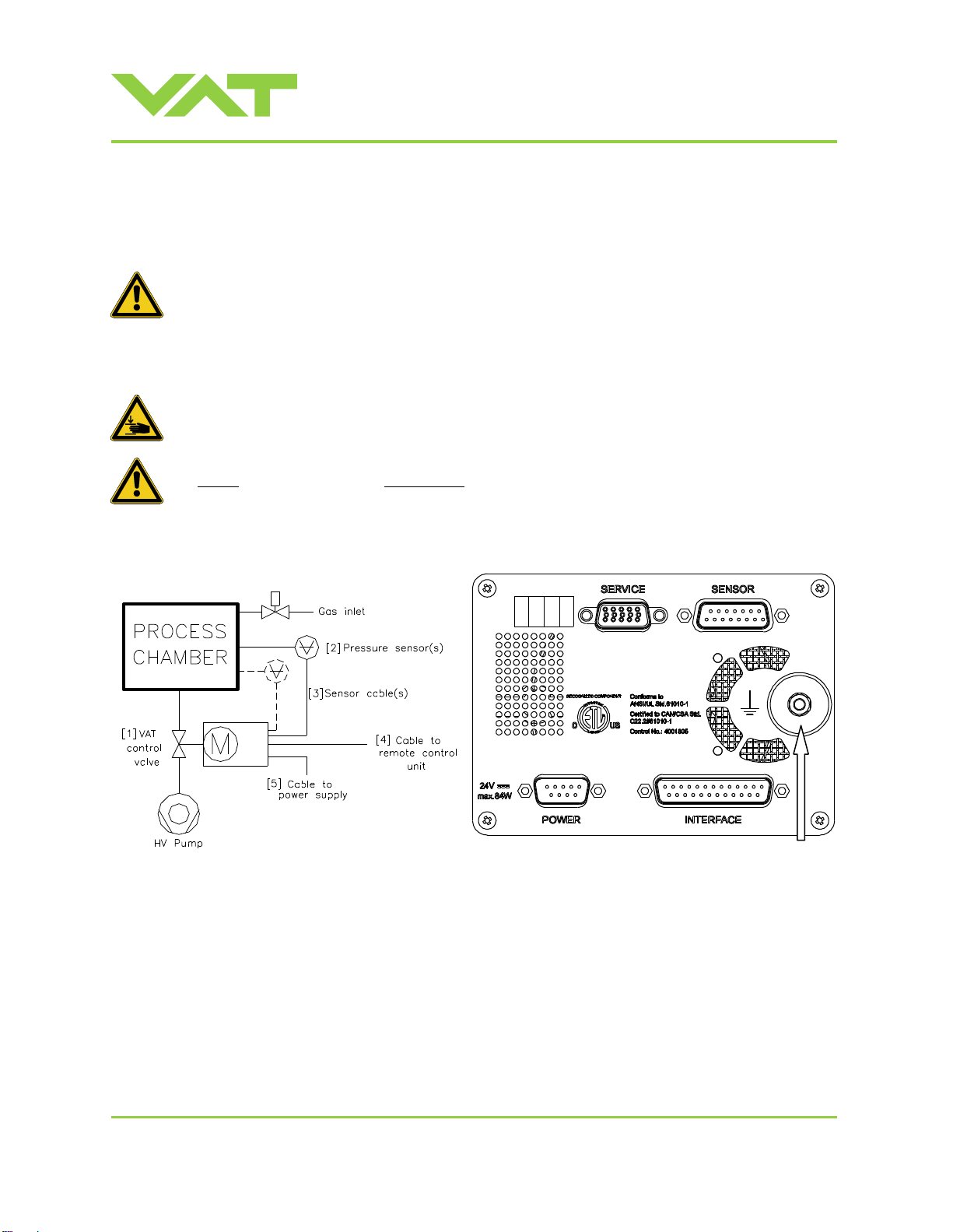

2Installation................................................................................................................................................................. 8

2.1 Unpacking........................................................................................................................................................ 8

2.2 Installation into the system .............................................................................................................................. 8

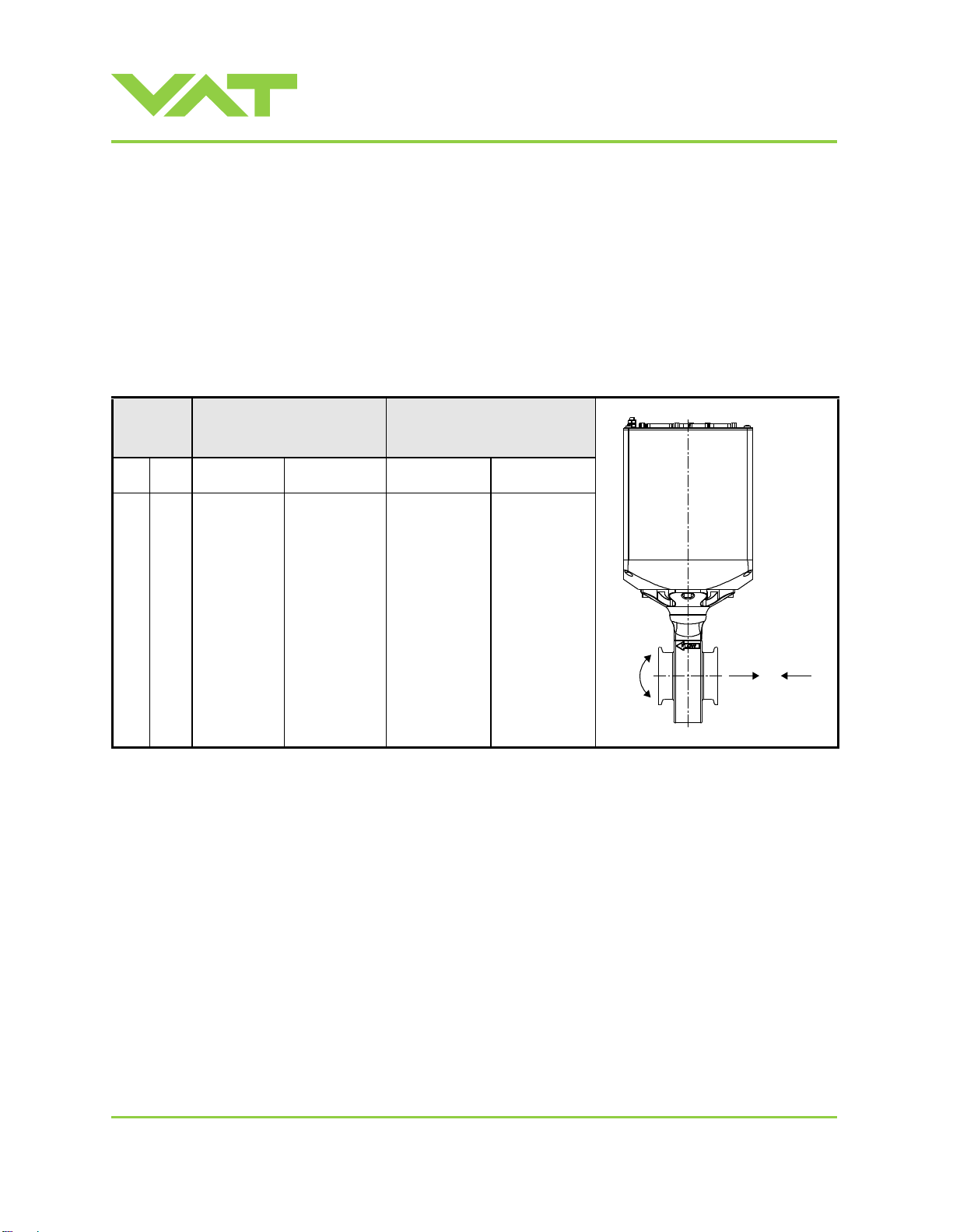

2.3 Tightening torque........................................................................................................................................... 10

2.3.1 Mounting of ISO-KF flanges .............................................................................................................. 10

2.4 Admissible forces........................................................................................................................................... 10

2.4.1 Admissible forces at controller .......................................................................................................... 11

2.5 Requirements to sensor connection .............................................................................................................. 12

2.6 Electrical connection...................................................................................................................................... 13

2.6.1 Ground connection............................................................................................................................ 13

2.6.2 Sensor supply concepts .................................................................................................................... 14

2.6.3 Power and sensor connection (+24 VDC sensors)............................................................................ 15

2.6.4 Power and sensor connection ( 15 VDC sensors) without optional SPS module............................. 17

2.6.5 RS485 interface connection .............................................................................................................. 19

2.6.6 Service port connection..................................................................................................................... 19

3Operation................................................................................................................................................................ 20

3.1 Introduction.................................................................................................................................................... 20

3.1.1 Local operation.................................................................................................................................. 21

3.1.2 Remote operation.............................................................................................................................. 21

3.1.3 Safety mode ...................................................................................................................................... 22

3.2 Operation under increased temperature........................................................................................................ 22

3.3 Behavior during power up.............................................................................................................................. 22

3.4 Behavior in case of power failure................................................................................................................... 22

3.5 Display information ........................................................................................................................................ 23

3.6 Setup procedure ............................................................................................................................................ 25

3.6.1 Interface configuration....................................................................................................................... 25

3.6.2 LOGIC I/O configuration.................................................................................................................... 27

3.6.3 Valve and sensor configuration......................................................................................................... 28

3.6.4 ZERO................................................................................................................................................. 28

3.6.5 Pressure control configuration........................................................................................................... 29

3.6.6 Control algorithms ............................................................................................................................. 31

3.7 Close valve .................................................................................................................................................... 35

3.8 Open valve..................................................................................................................................................... 35

3.9 Position control .............................................................................................................................................. 36

3.10 Pressure control............................................................................................................................................. 36

3.11 Tuning of pressure control performance........................................................................................................ 36

3.11.1 Tuning of pressure control (adaptive)................................................................................................ 37

3.11.2 Tuning of pressure control performance with fixed PI control............................................................ 42

3.11.3 Tuning of pressure control (soft pump).............................................................................................. 47

3.12 RS485 interface............................................................................................................................................. 50

3.12.1 Settings.............................................................................................................................................. 50

3.12.2 Schematics........................................................................................................................................ 50

3.12.3 RS485 network topology ................................................................................................................... 53

3.12.4 Connection cable drawing................................................................................................................. 53

3.12.5 Digital inputs...................................................................................................................................... 54

3.12.6 Command syntax............................................................................................................................... 55

3.12.7 Addressed communication................................................................................................................ 55

3.12.8 RS485 Control commands ................................................................................................................ 56

3.12.9 RS485 Inquiry commands................................................................................................................. 57

3.12.10RS485 Setup commands................................................................................................................... 62

3.12.11Error messages................................................................................................................................. 69

4Trouble shooting..................................................................................................................................................... 70

5Maintenance & repairs............................................................................................................................................ 73

5.1 Maintenance procedures ............................................................................................................................... 73