Contents

Table of Contents

1. Introduction, Features and Applications.......................................................................................................................1

Introduction ............................................................................................................................................................. 1

Features....................................................................................................................................................................1

Applications.............................................................................................................................................................1

2. Specifications............................................................................................................................................................... 1

Electrical Specifications .......................................................................................................................................... 1

Operating Environment and other Specifications.....................................................................................................2

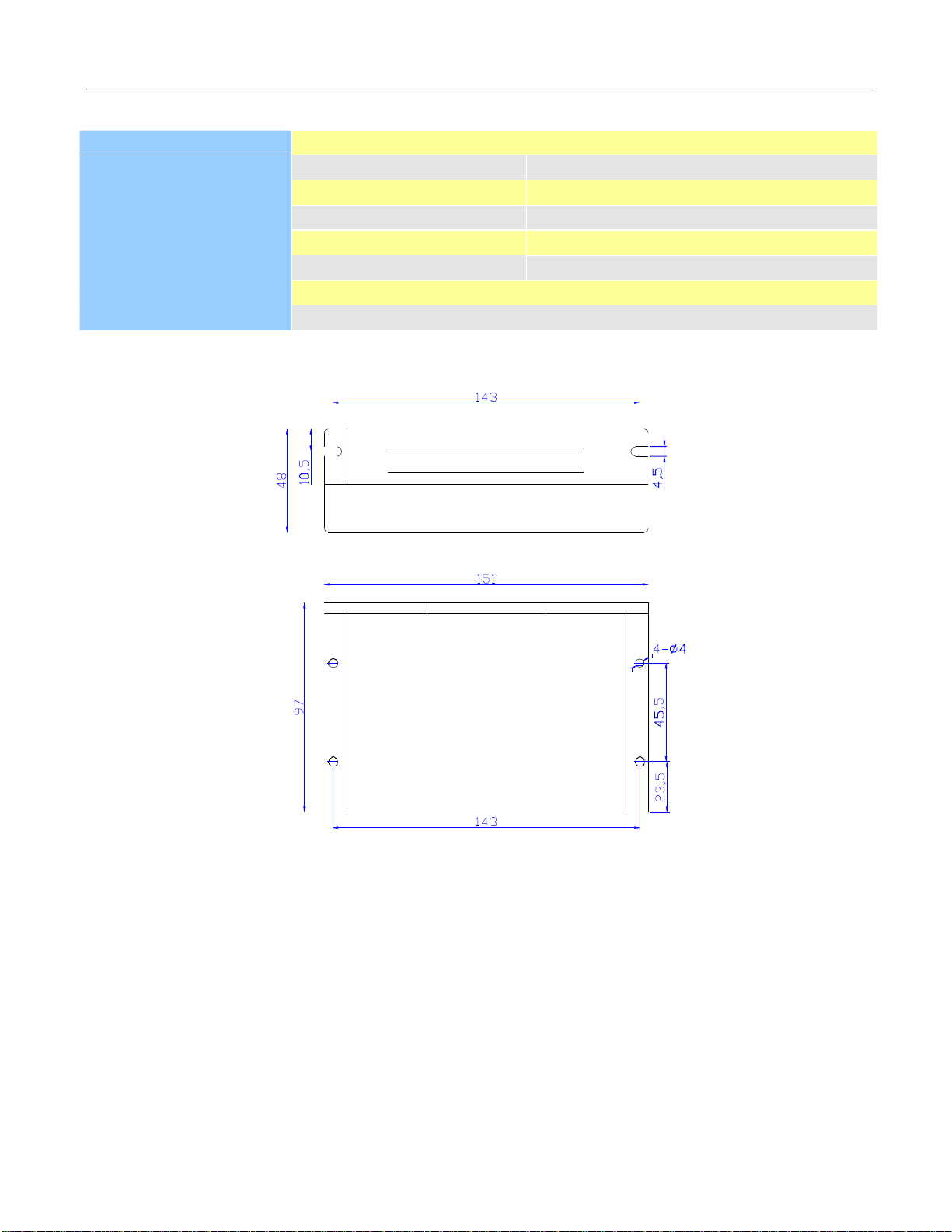

Mechanical Specifications........................................................................................................................................2

Elimination of Heat ................................................................................................................................................. 2

3. Pin Assignment and Description.................................................................................................................................. 3

Connector P1 Configurations................................................................................................................................... 3

Selecting Active Pulse Edge or Active Level and Control Signal Mode...................................................................3

Connector P2 Configurations................................................................................................................................... 4

4. Control Signal Connector (P1) Interface ......................................................................................................................4

5. Connecting the Motor..................................................................................................................................................4

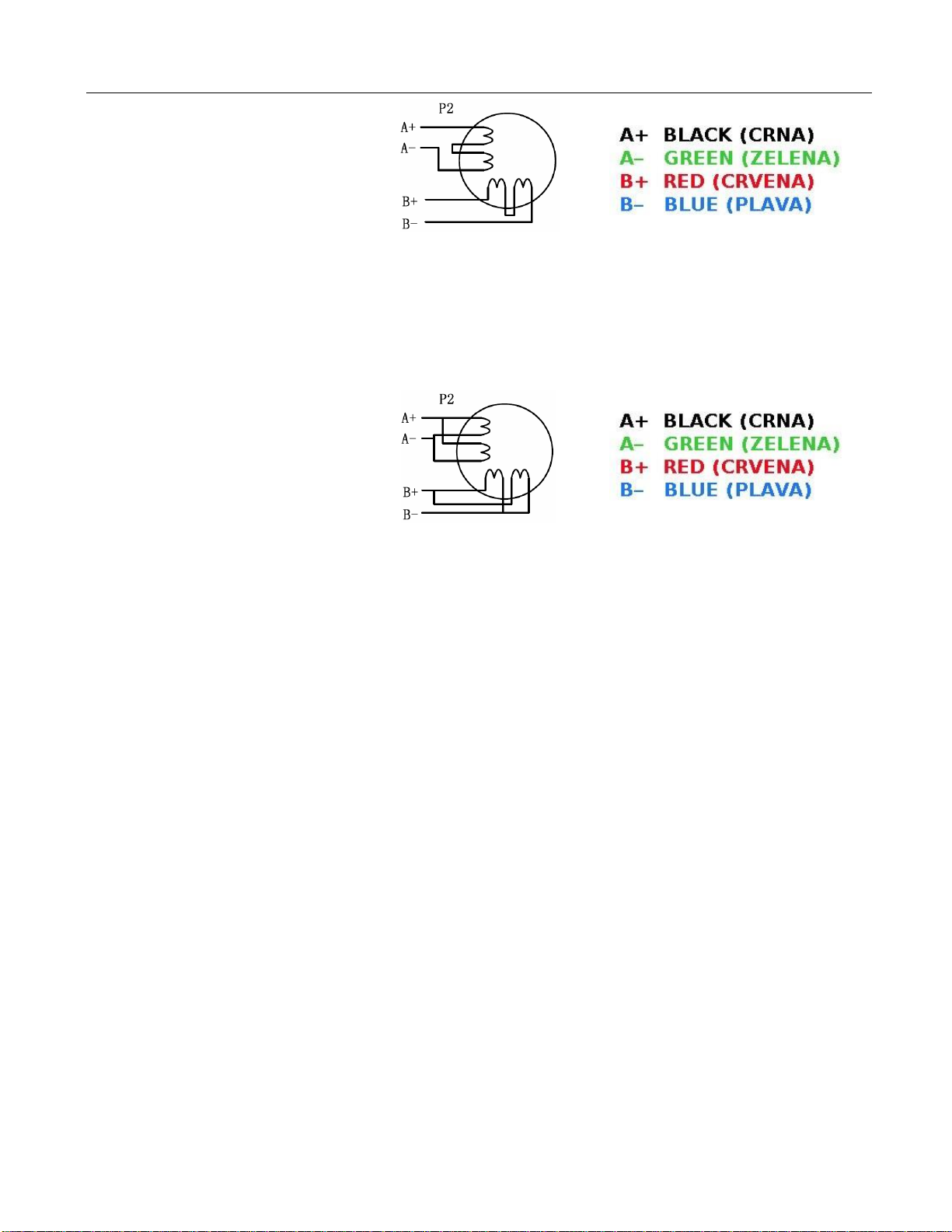

Connections to 4-lead Motors..................................................................................................................................4

Connections to 6-lead Motors..................................................................................................................................5

Half Coil Configurations ................................................................................................................................. 5

Full Coil Configurations...................................................................................................................................5

Connections to 8-lead Motors..................................................................................................................................5

Series Connections........................................................................................................................................... 5

Parallel Connections.........................................................................................................................................6

6. Power Supply Selection...............................................................................................................................................6

Regulated or Unregulated Power Supply................................................................................................................. 6

Multiple Drivers ...................................................................................................................................................... 6

Selecting Supply Voltage. ....................................................................................................................................... 7

7. Selecting Microstep Resolution and Driver Output Current........................................................................................ 7

Microstep Resolution Selection...............................................................................................................................7

Current Settings........................................................................................................................................................7

Dynamic Current Setting..................................................................................................................................8

Standstill Current Setting.................................................................................................................................8

28BAuto Tuning by SW4.........................................................................................................................................8

8. Wiring Notes................................................................................................................................................................ 9

9. Typical Connection...................................................................................................................................................... 9

10. Sequence Chart of Control Signals..........................................................................................................................10

11. Protection Functions.................................................................................................................................................10

12. Frequently Asked Questions.....................................................................................................................................11

Problem Symptoms and Possible Causes ...............................................................................................................11