9

Troubleshooting Guide

HydrX Quick Help - ATG Control Section 5 - HydrX System Alarm Troubleshooting

Vacuum Fault Actions

The HydrX system requires a minimum vacuum level of -1.25 psi on its pressure sensor for startup with new filters. If at least

-1.25 psi cannot be generated the following steps can be taken.

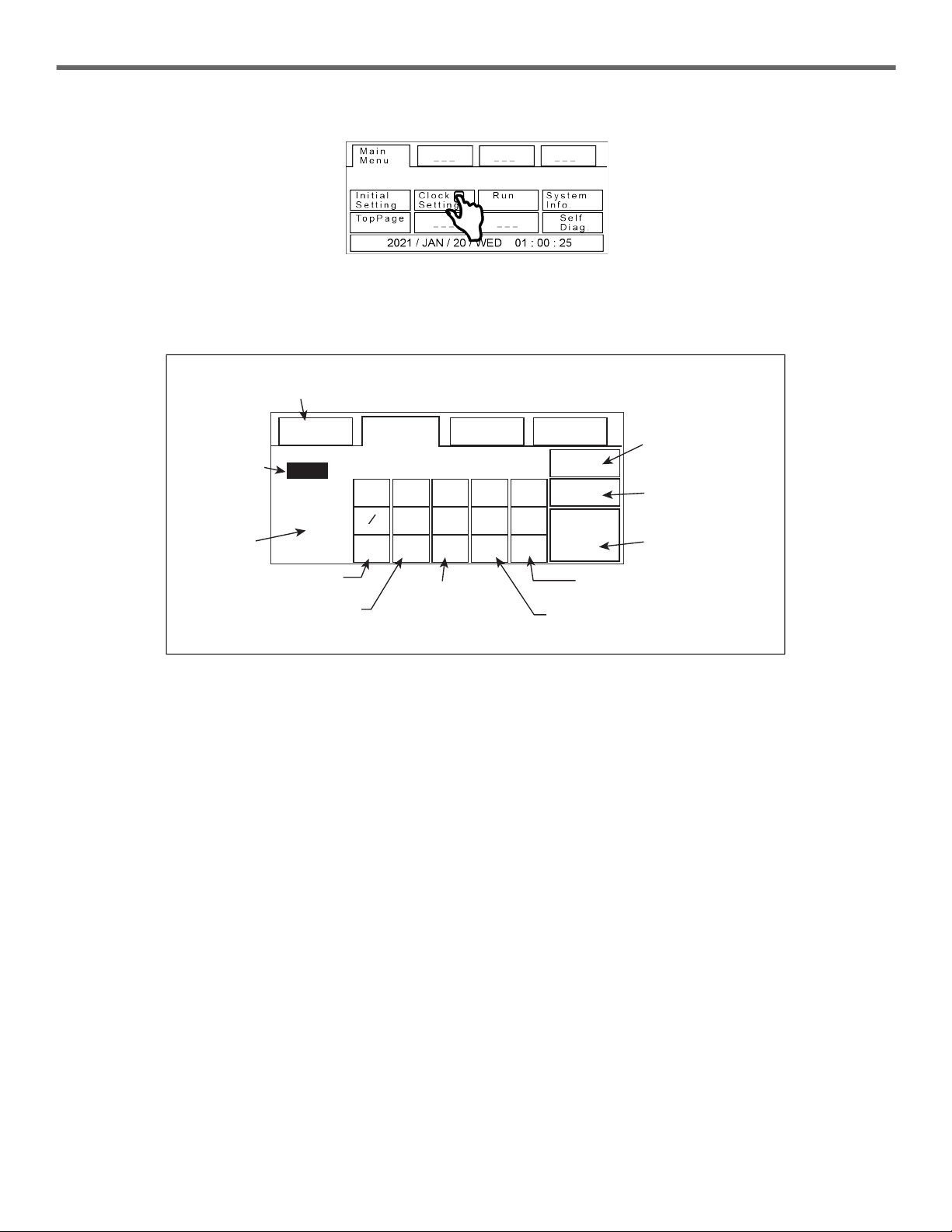

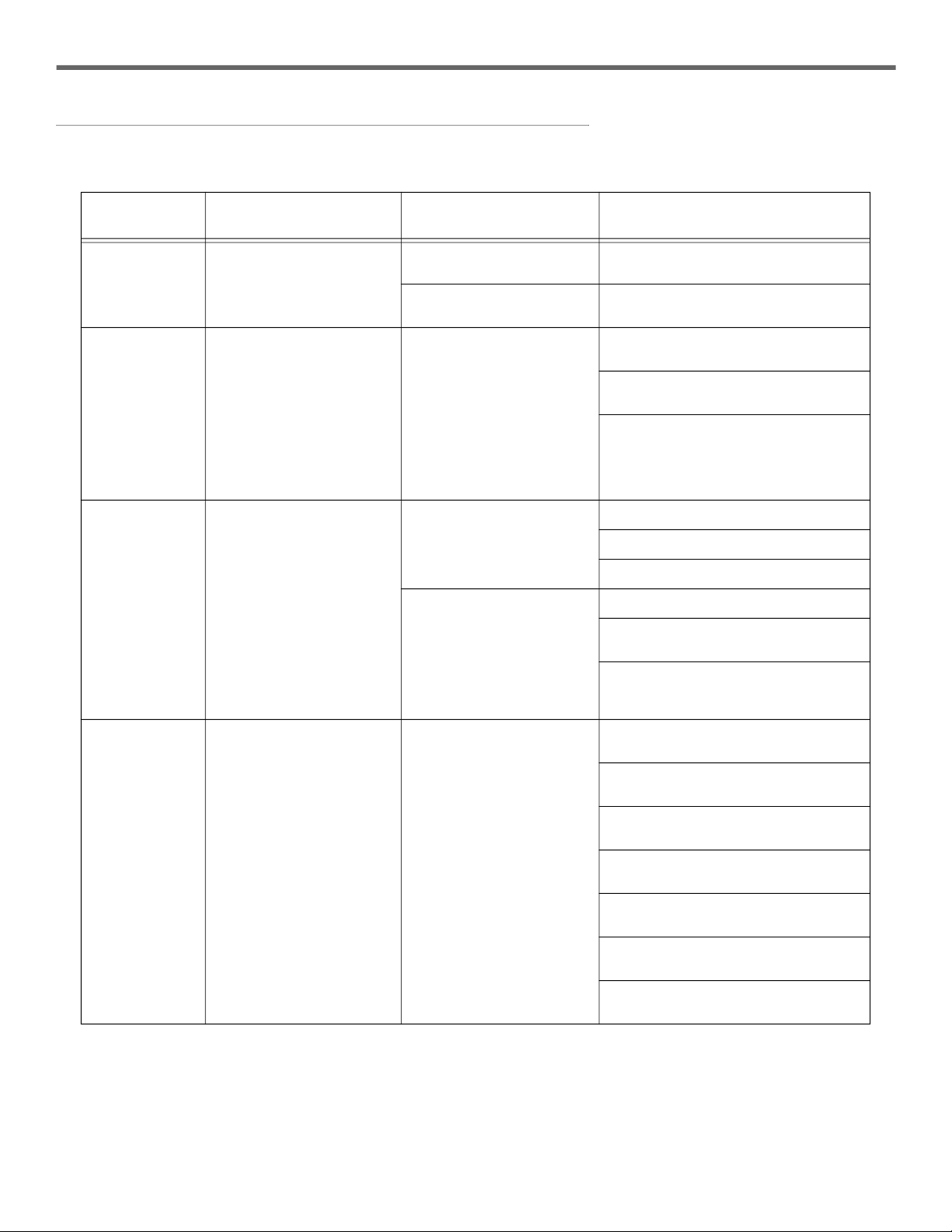

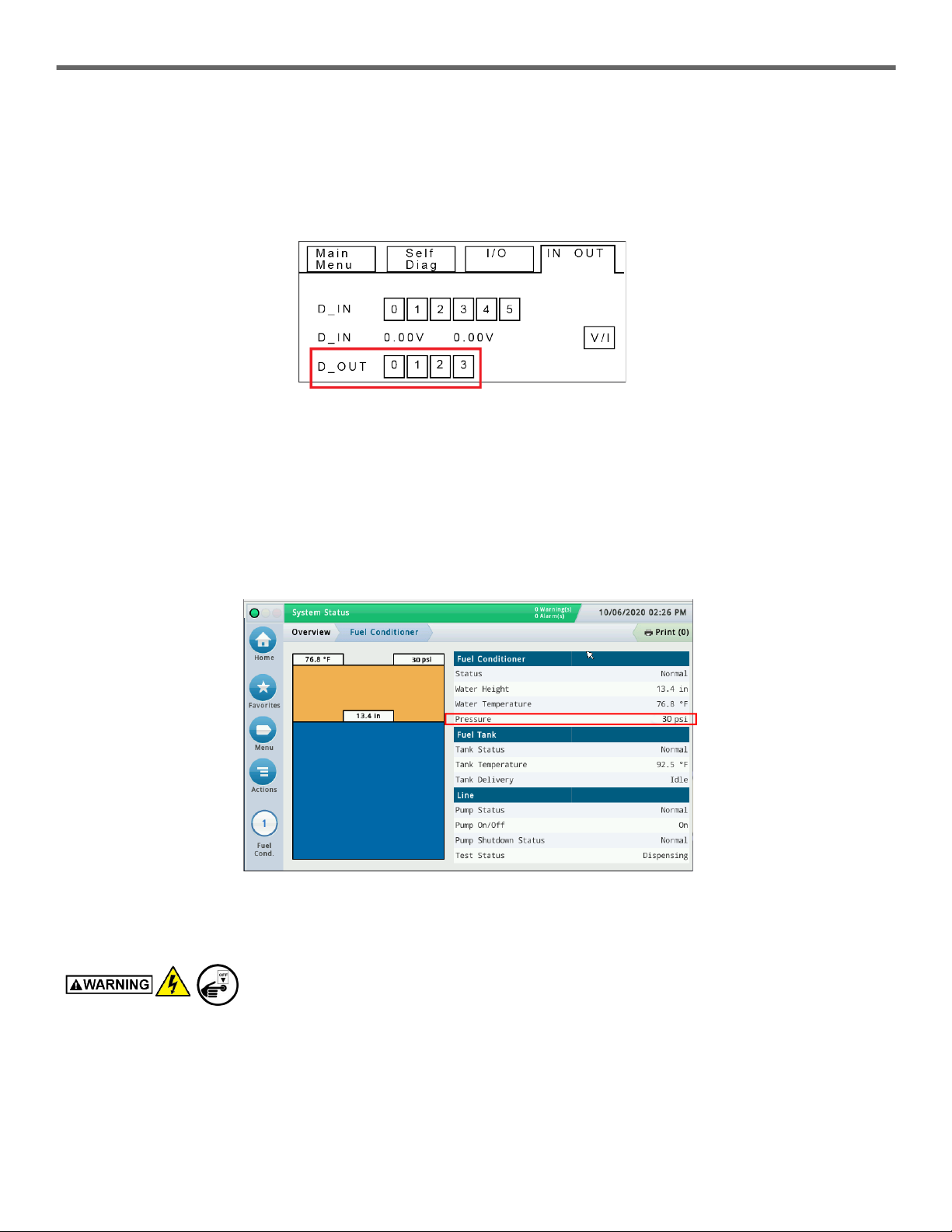

1. Enter the FCC Self Diag. screen by following the steps in “Accessing FCC Manual Control” above.

2. Turn on the STP and Outlet Valve (Touch 0 and 1 on the IN OUT screen). Observe the Pressure reading in the Fuel

Conditioner tab on the TLS-4xx HydrX Overview>Fuel Conditioner screen (see Figure 14).

3. If the vacuum level cannot reach at least -1.25 psi, de-energize the devices and verify general troubleshooting steps have

been followed before continuing.

4. Excessive Vacuum. If at system startup, the HydrX pressure sensor is reading more than -10 psi vacuum, an alarm will be

generated. This is generally due to a blockage in or damage to the WID.

Tag, lockout power to the STP.

- Close the STP Adapter ball valve.

- Remove the (3) 1/4" bolts securing the WID to the guide tube and raise the WID so the tubing is visible. Once damage

such as kinked tubing or excessive debris is corrected, repeat step 1 after power is restored to check vacuum levels.

5. Vacuum Loss during Idle Periods. 30 minutes after each HydrX cycle, a leak check is performed on the fuel conditioner

housing. Under normal circumstances the housing will hold a vacuum of around -1.5 psi during idle periods. If after 30

minutes from the last HydrX cycle the vacuum in the housing is between -0.75 and 0 psi, an alarm will be generated. This

indicates that there is a small leak in the system. At system startup verify that the general troubleshooting steps have been

followed.

a. If no leaks are visually present and the system cannot hold vacuum during idle periods the following steps can be

followed

- Run a Fill or New Filter cycle. Setting ‘Fill Time’ to 3 minutes allows for quicker troubleshooting.

- After running a complete Fill or New Filter Cycle, the clear tubing on the WID should be filled with fuel. Any presence

of bubbles or air cavities indicate a leak in the WID. This can be checked at the end of the cycle.

Tag, lockout power to the STP.

- Close the STP Adapter ball valve. Visually inspect tubing by removing the (3) 1/4" bolts securing the WID to the

guide tube and raising the WID so the tubing is visible. If any significant air leaks are present, contact technical

support for further action.

b. Uneven or obstructed valve sealing surfaces can also cause slow leaks in the system that will cause it to fail the idle

leak check.

Tag, lockout power to the STP.

- Close the STP Adapter ball valve and ensure that FC Outlet Valve (round body) was not accidentally loosened during

installation. Loosen valve coil nut and snug valve body by turning the knurled valve body clockwise.

- If the valve body was loose, tighten the coil nut and re-enable the system by unlocking the STP breaker, opening the

pump adapter ball valve and running a fill or new filter cycle. If the outlet valve body was tight, continue with the

following steps.

c. Debris accumulated in the valve seats can also cause slow vacuum loss. This generally applies to systems that have

been in service for an extended period of time, however, this can be an issue with highly contaminated retrofit sites or

construction debris in new installations.

Tag, lockout power to the STP.

- Close the STP Adapter ball valve.

- Remove the Siphon Cartridge from the HydrX manifold and inspect the screen. If heavy debris is present on this

screen and siphon cavity, the Inlet Valve sealing surfaces may also contain similar debris.