Probe/Thermistor Interface Module Installation Guide Module Positions and Labeling

2

Module Positions and Labeling

1. Modular consoles have three bays in which interface modules can be installed; Comm bay (left door), Power bay,

and Intrinsically Safe (I.S.) bay (right door). The Probe/Thermistor Interface Module is installed in the I.S. bay.

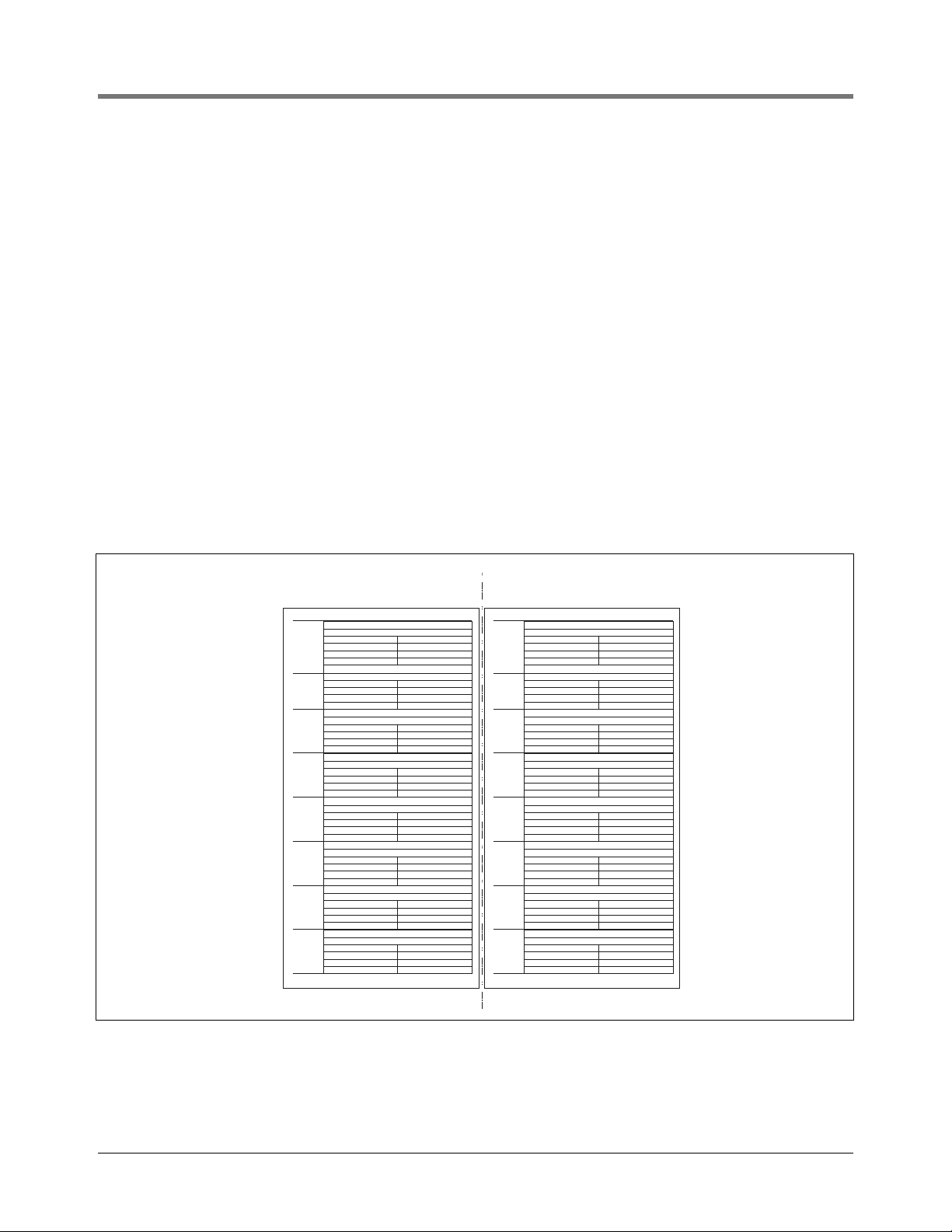

Figure 1. Console Interface Module Bays

In all cases, the position of all modules, their respective connectors, and the devices wired to the connectors

must be recorded to prevent improper replacement during installation or service. A circuit directory for Pow-

er and I.S. bay Interface Modules is adhered to the back of the right-hand door for this purpose.

During programming, module positions and the devices wired to each module are identified and stored in memo-

ry. If a connector is removed and reinstalled on a different module after programming, or if an entire module with

its connector is removed and reinstalled in a different module slot, the system will not properly recognize the data

being received.

2. If a system contains multiple modules of a single type (i.e., two Probe/Thermistor Interface Modules), they may be

swapped between their respective slot locations, however, the connectors must remain with their original

locations, not with the original modules.

WARNING

The equipment is used in location where lethal voltages and explosive vapors or flammable fuels

may be present.

Care must be taken when installing, servicing or replacing parts in the system or serious injury or

death from explosion, fire or shock may occur.

For this system:

1. Comply with the latest National Electric Code, federal, state, and local codes, and any other

applicable safety codes. In addition, take necessary precautions during installation, service,

and repair to prevent personal injury, property loss and equipment damage.

2. Refer servicing to trained and qualified personnel only.

3. Substitution of components may impair intrinsic safety.

4. Be sure AC power to the console is “OFF” before opening the console panel covers, plugging

in the module, and connecting probe and thermistor wires. Do not short any voltage across

any barrier terminal including sensors or probes.

OFF

console\350rjmods.eps

Intrinsically

Safe Bay

Permissible

Modules

(Limit 8

per console)

Power

Bay

Permissible

Modules

(Limit 8

per console)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

12 34

Power Bay

Slot Numbers

Power Bay

Slot Numbers

I.S. Bay

Slot Numbers

Comm Bay

Slot Numbers

Comm Cage*

*See Serial Comm Installation Guide

for permissible modules.