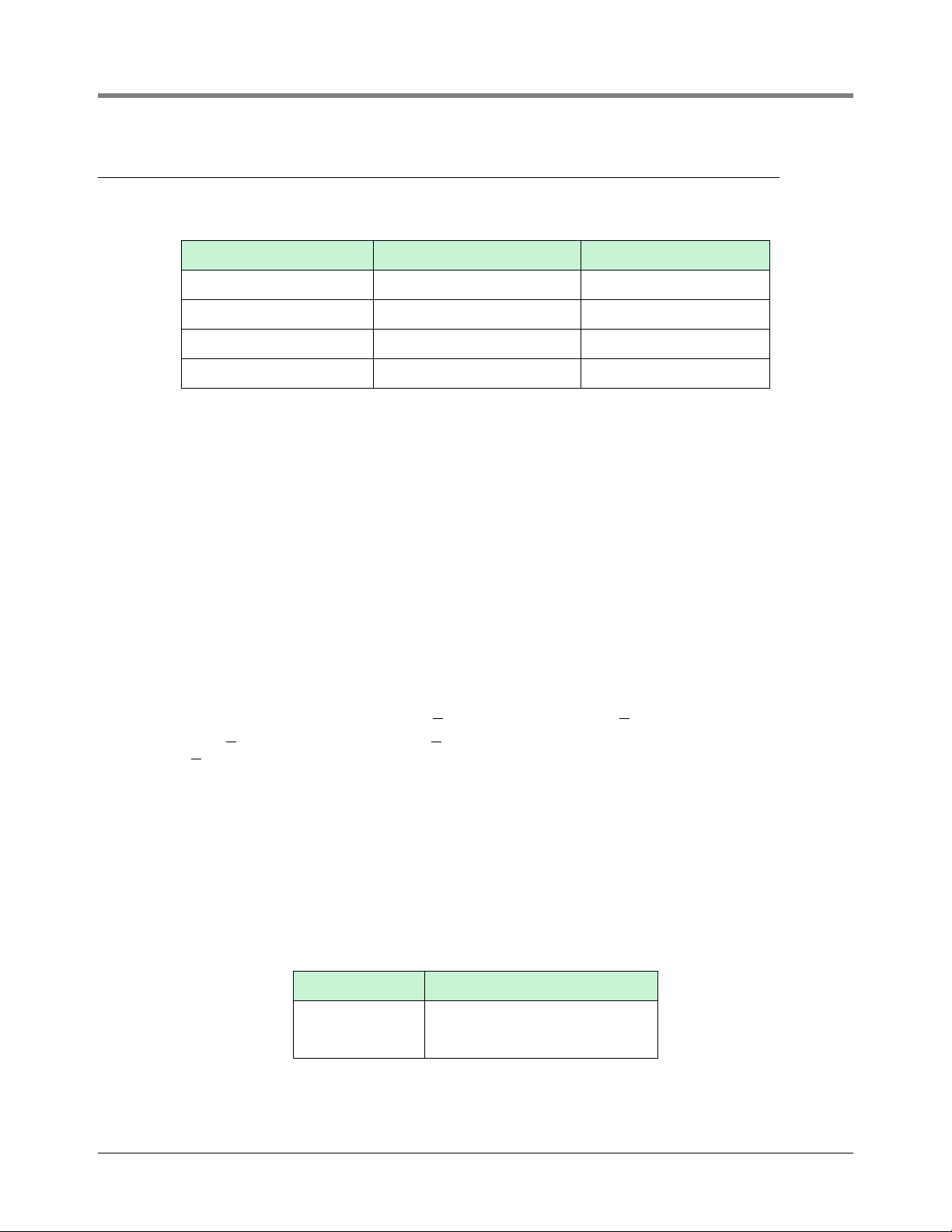

Table of Contents

iii

Introduction

Contractor Certification Requirements ..............................................................................2

Related Manuals ...............................................................................................................3

Safety Precautions ............................................................................................................4

Safety Warnings ...............................................................................................................5

VaporTEK Configurations .................................................................................................5

VaporTEK Pump Certifications & Markings .....................................................................6

Safety Certification ...................................................................................................6

Hazardous Area Installation Instructions ..................................................................6

Equipment Marking...................................................................................................6

Material Compatibility With Constituents Of The Potentially

Explosive Atmosphere..............................................................................................7

TUV Certification ......................................................................................................7

VaporTEK Kits ..................................................................................................................7

VaporTEK Pump, ATEX/IECEX/ITRI Kit - P/N 900612-001 ....................................7

VaporTEK Pump, ATEX/IECEX Kit - P/N 900882-001 (Salzkotten).........................8

VaporTEK Pump, PCEC Kit - P/N 900869-001 (China PCEC Version) ...................8

VaporTEK-3 Controller Board Kit - P/N 900895-001 ................................................9

VTEK-3 Pulse Interface Adapter Kit - P/N 900905-001..........................................11

VaporTEK High Voltage Relay Kit - P/N 900664-001.............................................11

VaporTEK Valve Adapter Interface Kit - P/N 900XXX-001.....................................12

VaporTEK Pump Characteristics ....................................................................................12

VaporTEK Pump Specifications .............................................................................13

VaporTEK Controller .......................................................................................................14

VaporTEK Controller Pulse Interface (Optional) .............................................................15

VaporTEK Pulse Interface Adapter Board (P/N 900900-001) Jumpers .................15

VaporTEK Valve Adapter Board (Optional) ....................................................................16

VaporTEK Pump Configuration ......................................................................................18

Installation

VaporTEK Pump .............................................................................................................19

VaporTEK-3 Controller and VaporTEK Pulse Interface Installation ................................21

VaporTEK-3 Controller Board InstallatioN..............................................................21

VaporTEK Pulse Interface Adapter Board Installation............................................22

Alternate VaporTEK-3 Controller Board Mounting ..........................................................24

Retrofit Installation Of VaporTEK-3 Controller Board .....................................................25

Rules To Be Observed ...........................................................................................25

Retrofit Kits .............................................................................................................25

Site Preparation......................................................................................................26

Retrofit Procedure ...........................................................................................................26

VaporTEK-3 Controller Board Replacement ..........................................................26

VaporTEK-3 Controller Board/New VaporTEK Pump Replacement ......................26

Wiring Schematics

VaporTEK Wiring ............................................................................................................27

Communication Setup - VaporTEK Interface

Setup with Laptop ...........................................................................................................34

VaporTEK Calibration

Manual Calibration Using The Speed Setup If High Voltage Signals M1

And M2 Are Used ...........................................................................................................44

Equipment Required...............................................................................................44

Initial Setup.............................................................................................................44