1General Information

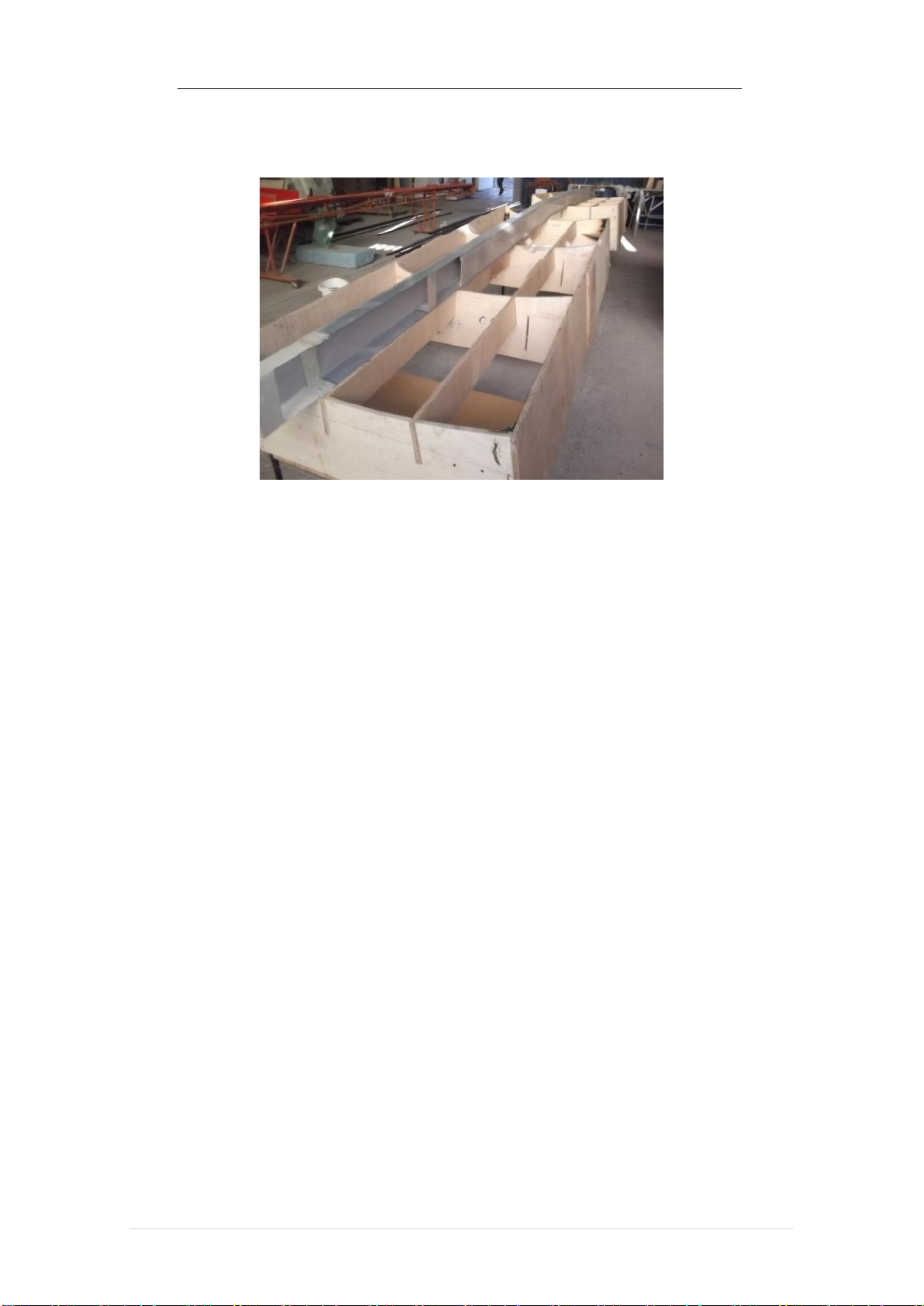

Congratulations on selecting the Veloce 400 as your personal aircraft build kit. If

you've built any other composite aircraft before, you'll be pleasantly surprised at the

simplicity and ease with which this project will progress. If this is your first build on a

project, please pay particular attention to all phases of instruction and you will also be

guided to a satisfactory completion of this excellent aircraft. The theme under the entire

project development line is focused on the simplicity in the construction and operation of

the complete aircraft. This manual provides detailed step-by-step instructions for

assembling the Veloce 400 aircraft kit. However, the basic instructions in each section

assume a certain degree of familiarity and experience in building with composite material.

The introductory chapters will define several terms and provide detailed assistance on

many of the repeated operations, but if you do not have any experience, it is recommended

to look at other reference texts and possibly some test projects with composite

construction. Working with some practice in using composite material is strongly

recommended.

If during construction you have any questions or concerns about the construction

procedure, do not continue until you obtain the required information or skill to complete

the procedure correctly. If you are not knowledgeable about fiberglass construction

techniques, please consult some of the referenced sources for such knowledge before

starting construction. It is also important to have someone with previous experience help

you and provide training in these procedures. Changes to the aircraft design or specified

construction procedures must not be made without the prior approval of VOLATO.

Unauthorized changes can create hazardous conditions impacting aircraft safety and/or

structural integrity. Failure to comply with these warnings and/or other instructions and

precautions contained in the manual coan result in an unsafe aircraft with the potential for

increased injury or possible fatality.